Bucket Conveyor Manufeaturer

Bucket Elevator

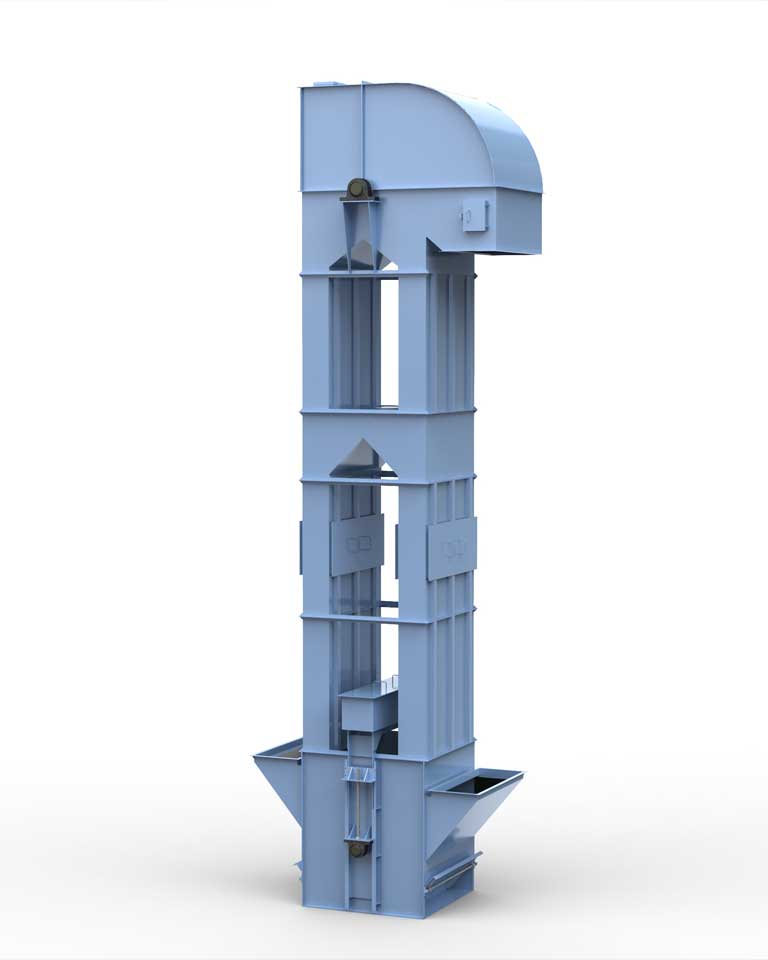

Bucket conveyor, also known as bucket elevator, is a transportation machine that continuously conveys powdery and granular materials vertically upwards.

What is a bucket conveyor

A bucket conveyor is a kind of transportation machinery that continuously conveys powdery and granular materials vertically upward. It is suitable for conveying powdery and granular garbage after crushing and screening. Because of its simple structure, small footprint, shortest conveying distance, large lifting height, and good sealing performance, it can avoid environmental pollution and is widely used in waste treatment.

However, the bucket conveyor can only transport powdery and granular materials and has poor adaptability to overloading. Sometimes the hopper is not clean, which is easy to cause blockage, the conveying efficiency is not high, and the hopper and traction mechanism are also easily damaged. The bucket conveyor consists of a driving device, an upper section, a middle casing, a lower section, a belt or chain, a bucket body, and a backstop brake. The biggest feature of the bucket conveyor is that it can be installed at any inclination within the horizontal and vertical ranges and arranged in many shapes. Read More: Bucket Conveyor Wikipedia

Classification and characteristics of bucket conveyor

| Item | Type | Main Feature |

| Traction member | Adhesive tape | Light weight, low noise |

| Chain | Large arc, can transport high temperature materials | |

| Hopper form | Deep bucket | With a deep round bottom hopper, it is suitable for conveying dry, loose and easy-to-throw materials |

| Shallow bucket | With a pouring round bottom hopper, it can convey wet, agglomerated and difficult-to-throw materials. | |

| Loading method | Scoop | The material is at the bottom and is dug out by the hopper, and only small particles and less abrasive materials are transported |

| Load | The material is delivered from the hopper, and the bottom slope of the feed inlet forms an angle of 45°C or 60°C with the horizontal plane. It can transport materials with large lumps and abrasiveness | |

| Unloading method | Centrifugal force | The running speed of the bucket is high, and the material is thrown out by centrifugal force |

| Full dismantling | The speed of the bucket is relatively low. In order to make the material fall into the discharge port, a compression sprocket is generally installed on the discharge side near the head sprocket to press the chain to the rear. |

Bucket conveyor conveying principle and structure

The conveying principle of the bucket elevator is that the hopper scoops up the material from the lower storage tank, lifts it to the top with the conveyor belt or chain, bypasses the top wheel and then turns downward, and pours the material into the receiving tank

The transmission belt of the bucket elevator with transmission is generally a rubber belt, which is installed on the lower (or upper) driving roller and the upper (or lower) redirecting roller. The chain-driven bucket elevator is generally equipped with two parallel transmission chains, a pair of transmission sprockets on the upper (or lower) surface, and a pair of redirecting sprockets on the lower (or upper) surface. Bucket elevators are generally equipped with a casing to prevent dust from flying.

Bucket Conveyor Loading and Unloading

Two Load Moethods

- Pull-out loading. The hopper is loaded by digging out the material at the tail. It is mainly used for conveying powdery and granular materials, and the resistance is not large when digging out, and the moving speed of the hopper is 0.8-2m/s.

- Inflow loading. Material flows directly into the hopper to realize loading. The inflow type is used to transport bulky or abrasive materials. The inflow hoppers should be closely connected to prevent material from being scattered between the hoppers. The moving speed of the hopper is less than 1m/s.

Uninstall

There are three types of bucket elevator unloading, namely centrifugal, centrifugal-gravity and gravity.

Five requirements for daily maintenance of bucket elevators

- The upper and lower bearings should be lubricated regularly to maintain good working conditions.

- Regularly check and lubricate the reducer, keep the oil quantity appropriate, avoid insufficient or excessive, and replace the oil on time.

- Regularly maintain and clean the moving parts, and check the wear of chains, sprockets, drive belts, rollers, and hoppers. The inspection should be carried out when the machine is shut down and the power supply is cut off.

- Regularly check and adjust the tensioning device. When the tightening stroke is less than 1/5 of the specified value, the length of the traction member can be cut off (usually shortened by one bucket distance) to restore the tightening stroke, thereby eliminating the possibility of the hopper being scratched by the bottom of the feed port. For the screw tensioning device, it is necessary to maintain the normal working tension of the traction parts.

- Regularly check the wear of the backstop, and replace it when the ratchet, pawl, and roller are severely worn to keep the backstop working reliably.

Nantong United Heavy Machinery Co., LTD(UHM) has always been an innovative pioneer in the technological development of vibrating machines, such as vibrating feeders, conveyors, screening, and drying. UHM is not only an equipment manufacturer but also a solution provider. Questions no matter whether bulk & granular or powder material processing, our experienced engineers are always able to offer the best solutions.