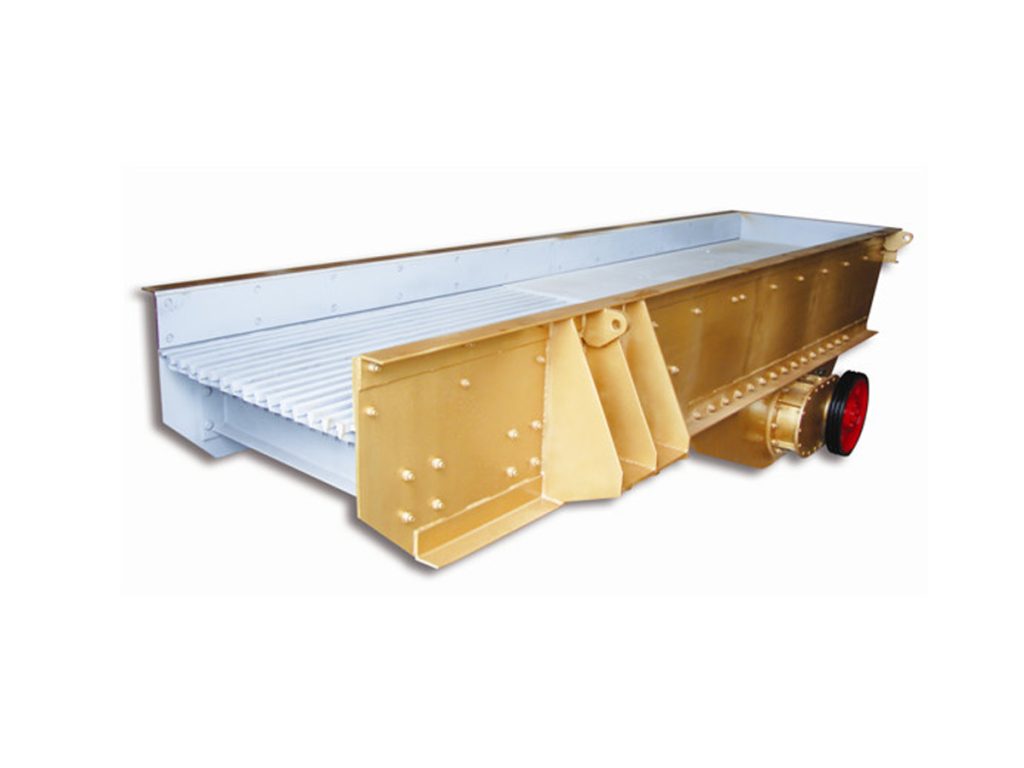

Grizzly feeder

vibrating grizzly screen

Experts in Vibrating Grizzly Screen. Have 30+ Years of Experience in Grizzly Feeder.

Hot Sale High-Quality Vibrating Grizzly Feeder Online from China.

What is a vibrating grizzly Feeder screen?

The Vibrating Grizzly Screen(also named Grizzly Feeder, Grizzly Screen ) is used for the uniform feeding of bulk materials in front of the coarsely crushing machine. At the same time, due to the function of the bar screen surface, it can also remove finely crushed materials such as soil, achieve pre-screening function, and improve the coarse crushing capacity. Especially suitable for the hydropower industry, construction stone, metal ore, and other materials before coarse crushing.

grizzly feeder working principle

The Vibrating Grizzly Screen (Grizzly Feeder) is mainly composed of a pair of vibration motors with the same performance parameters as the excitation source. When the two vibration motors run in opposite directions at the same angular velocity, the inertial force generated by the eccentric block is repeatedly superimposed or canceled in a specific phase. Thereby a huge synthetic excitation force is generated, which makes the body vibrate on the support spring forcibly, and the vibration is used as the driving force to drive the material to slide and throw on the trough so that the material moves forward continuously to achieve the purpose of feeding. When the material passes through the sieve bars on the tank body, the smaller materials can fall through the gap of the sieve bars without going through the next crushing process, which has the effect of screening.

In the production process, the Vibrating Grizzly Feeder can uniformly, regularly, and continuously feed the block and granular materials from the storage bin to the receiving device. In the sand and gravel production line, it can continuously and evenly feed the crushing machinery. It is widely used in crushing and screening combined equipment in metallurgy, coal mine, mineral processing, building materials, chemical industry, abrasives, and other industries.

Structure and Feeding Process

The Vibrating Grizzly Feeder consists of a pan section at the feed end to receive and start segregating the material. The discharge end consists of a grizzly section with openings that allow the undersized material to pass before discharging into the crusher. The feeder is mounted on springs and vibrated via a mechanism located underneath the feeder pan, protecting it from misfed material that fails to reach the feed hopper. The vibration force is angled to the feeder, pointing toward the discharge end. This action of the vibrator forces the material toward the discharge end while segregating the material, causing the finer particles to move toward the bottom of the load.

As the material travels to the grizzly section, the finer material settles to the bottom and passes through the openings in the grizzly. This bypassed material decreases the amount of material going into the crusher, reducing the size of the crusher required as well as the wear inside the crusher. The bypassed material can be combined with the material going through the crusher on under the conveyor. This prescreened material protects the under conveyor from the impact of the material exiting the crusher. The prescreened material can be segregated as a product, or it can be discarded if the fines in the material are contaminated.

Advantages

- Vibration steady

- Reliable

- Long-life advantages

- Can crusher continuously and evenly feed?

- While the front-end design for feeding special bars structure

- Can the material in the soil and crushing grain level in the feed material separation process out

- Meet the crushing and screening job requirements

- Is a sand and gravel crushing and screening system in the field ideal primary feeding equipment.

Features

The grizzly screen has a firm chute body structure and bears heavy compartment pressure, heavy impact load, and high strength of machine body, which is the precondition to satisfy thick segment feeding operation condition as a qualified primary vibrating feeder.

- Small size, lightweight, and simple structure.

- Easy installation and maintenance, low operating costs.

- High efficiency and large feeding capacity.

- Low noise, low power consumption, high power factor.

- Smooth vibration, uniform feeding, and long service life.

- Through the double gear rotates, the eccentric shaft generates linear vibration.

- The machine feeding uniform, stable, high bars strength, wear resistance, more suitable for continuous processing of hard, high wear resistance of materials

- It also has a strong body structure, feeding capacity, and lower overall installation height advantages.

- Stable vibration, reliable operation, and long service life

- Adjustable excitation force, can change and control flow at any time, easy to adjust and stabilize

- Feeding stable

Application

Grizzly feeders (Vibrating Grizzly Screen) have good performance in the quarry, construction, road building, bridge construction, quarrying, recycling, aggregates, and cement industries. Almost all kinds of minerals &rocks and some other materials processing plants can use the vibrating feeder.

It is widely used in crushing and screening combined equipment in metallurgy, coal mining, mineral processing, building materials, chemical industry, abrasives, and other industries.

Applicable materials: granite, marble, basalt, limestone, quartz, river pebble, copper ore, iron ore, etc.

Specification

| Model | Maximum Feed Size (mm) | Processing capacity (t/h) | Installation angle | Motor Power | Weight(kg) |

| (kw) | |||||

| GZD-250×75 | 300 | 100 | 0-10 | 2×1.5 | ≈1100 |

| GZD-360×100 | 500 | 150 | 0-10 | 2×3.0 | ≈2100 |

| GZD-420×120 | 600 | 200 | 0-10 | 2×4.5 | ≈4800 |

| ZSW-380×95 | 500 | 100-150 | 0 | 11 | ≈5100 |

| ZSW-420×110 | 580 | 200-250 | 0 | 15 | ≈6100 |

| ZSW-490×110 | 580 | 200-300 | 0 | 15 | ≈6700 |

| ZSW-590×130 | 700 | 300-100 | 0 | 22 | ≈7900 |

| ZSW-600×130 | 700 | 400-500 | 0 | 22-30 | ≈8200 |

| ZSW-600×150 | 800 | 500-700 | 0 | 30-37 | ≈9800 |

| ZSW-600×160 | 1000 | 650-800 | 0 | 37 | ≈11000 |