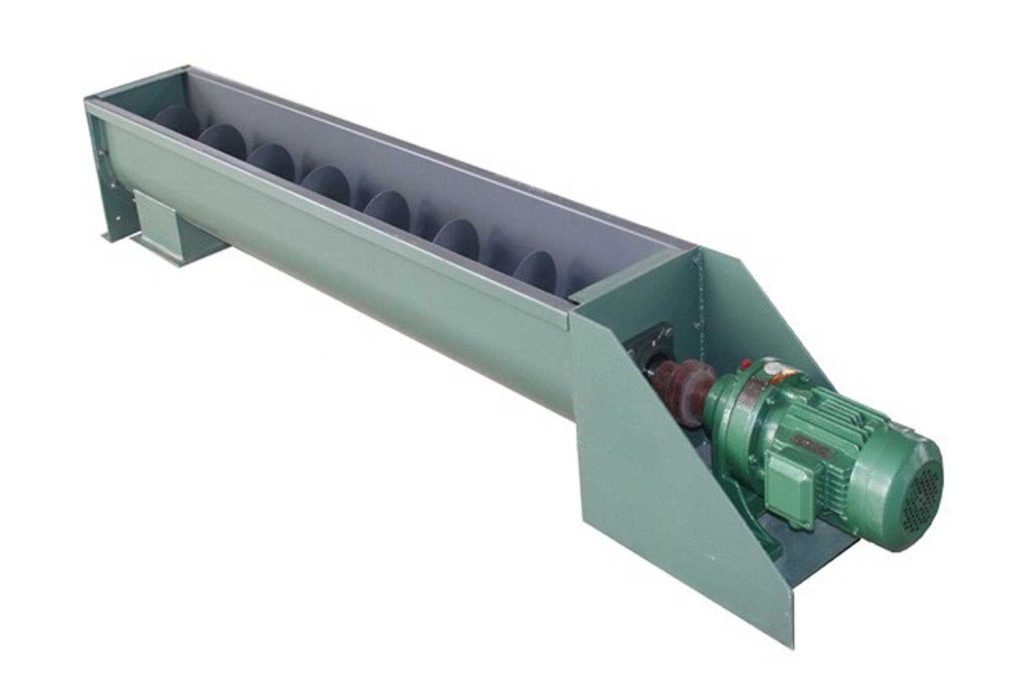

LS-type screw conveyor

LS screw conveyor

LS-type screw conveyor (hereinafter referred to spiral machine) structure, advanced technical indicators, head, tail bearing shell move, the middle hanging bearing rolling, moving interchangeable two structures located dustproof seals, cleaning device has a discharge end, the whole low noise, adaptable, easy operation and maintenance, expected out layout flexibility. Read More: screw conveyor wikipedia

- Delivery capacity: 2.2-48 (m³/h)

- Motor power: 1.6-78 (kw)

LS type screw conveyor is widely used in various industries, such as building materials, chemical industry, electric power, metallurgy, coal, grain and other industries. High reliability, long life, strong adaptability, easy installation and maintenance. It is suitable for horizontal or inclined conveying of powdery, granular and small block materials, such as coal, ash, slag, cement, grain, etc., and the temperature of the material is less than 200 °C.

Applications

Screw conveyor is widely used in various industrial sectors such as building materials, electrical, chemical, metallurgy, aluminum and magnesium, coal, machinery, light industry, food and food industries; used in horizontal or less than 20 ° angle, conveying powder, granular and small fast-like materials, such as cement, coal, grain, fertilizer, ash, sand and other material temperature below 200 ℃.

Screw conveyor should not transport perishable, viscous, easy caking materials because these materials at the time of delivery will be binding on the screw and rotates without moving forward or volume of material in the hanging bearing formation plug, leaving the screw machine is not working properly.

LS-type screw machine screw diameters from 100 mm to 800 mm, a total of nine kinds of rules, the length from 4 m to 70 m, at intervals of 0.5 m of a block, the selection criteria should be in line with nominal length, optional special needs in section presented separately.

Read More: Vibrating Conveyor, Conveyor Vibration System

Screw Conveyor Design Standards

LS series screw conveyor is designed and manufactured according to JB/T7679-95 “Screw Conveyor” standard, and it is a replacement product of GX screw conveyor. The head and tail bearings are moved to the outside of the housing. The suspension bearings are sliding bearings with dust-proof sealing devices. The bearing pads are generally made of powder metallurgy, and the cement is conveyed using felt bearing pads. The suspension shaft and the screw shaft are connected by sliders. When disassembling the screw, There is no need to move the driving device, no need to move the screw when disassembling the suspension bearing, and the suspension bearing can be lubricated without removing the cover plate. The whole machine has high reliability, long service life, strong adaptability, and convenient installation and maintenance.

LS type screw conveyor working principle

The rotating helical blades of the LS type screw conveyor push the material to be conveyed by the screw conveyor. The force that prevents the material from rotating together with the screw conveyor blades is the material’s own weight and the frictional resistance of the screw conveyor casing to the material. The spiral blades welded on the rotating shaft of the screw conveyor have different surface types such as solid surface type, belt type surface type, and blade surface type according to the different materials to be conveyed. The screw shaft of the screw conveyor has a thrust bearing at the end of the material movement direction to give the screw axial reaction force with the material. When the length of the screw conveyor is long, an intermediate suspension bearing should be added.

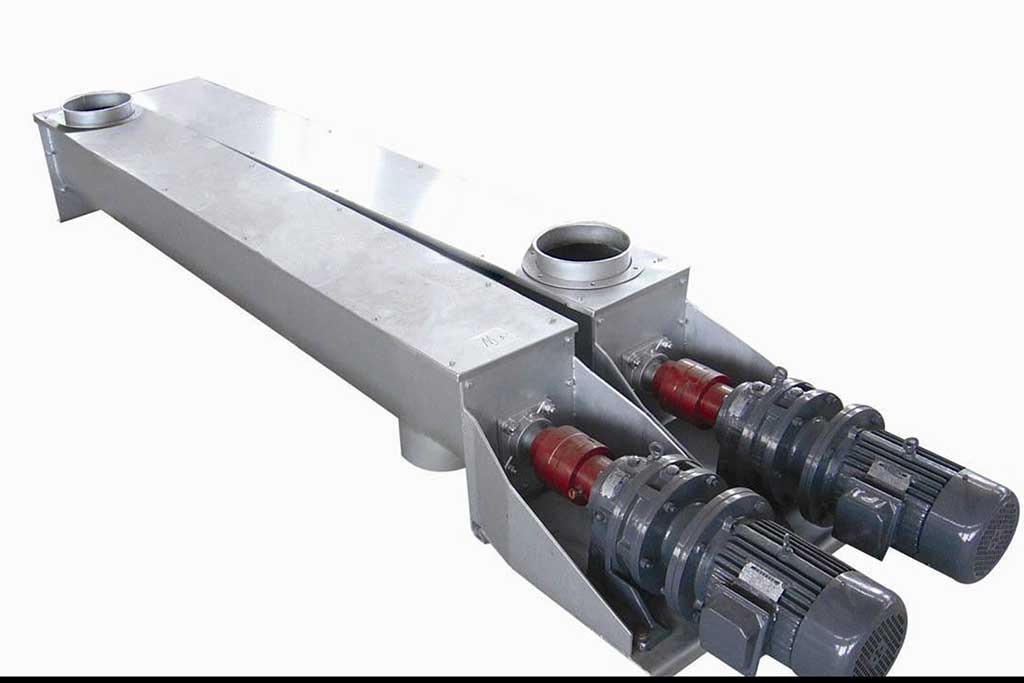

Press the rotary machine drive is divided into two kinds

- C1 Method – When screw conveyor length is less than 35m, single-ended drive.

- C2 system of law – screw machine is greater than 35m, double-ended driving.

According to the spiral machine intermediate bearing types are divided into:

- M1 is a rolling bearing, the 80000 type sealed bearings, shaft cover and sealing structure, commonly used in is not easy to come on, no gas or oil pollution to the material, the sealing effect is good, the bearing life is long, the output of material temperature ≤ 80 ℃ (order can not specify)

M2 – for the sliding bearing, a dustproof sealing device, used in the conveying high temperature (> 80 ℃), or transporting liquid material.

Technical parameters of LS type screw conveyor specification

| Model | 200 | 250 | 315 | 400 | 500 |

| Model | 200 | 250 | 315 | 400 | 500 |

| Pitch | 200 | 250 | 315 | 355 | 400 |

| n | 100 | 90 | 80 | 71 | 63 |

| Q | 13 | 22 | 31 | 62 | 98 |

| n | 80 | 71 | 63 | 56 | 50 |

| Q | 10 | 18 | 24 | 49 | 78 |

| n | 63 | 56 | 50 | 45 | 40 |

| Q | 8 | 14 | 19 | 39 | 62 |

| n | 50 | 45 | 40 | 36 | 32 |

| Q | 6.2 | 11 | 15.4 | 31 | 50 |

Nantong United Heavy Machinery Co., LTD(UHM) has always been an innovative pioneer in the technological development of vibrating machines, such as vibrating feeders, conveyors, screening, and drying. UHM is not only an equipment manufacturer but also a solution provider. Questions no matter whether bulk & granular or powder material processing, our experienced engineers are always able to offer the best solutions.