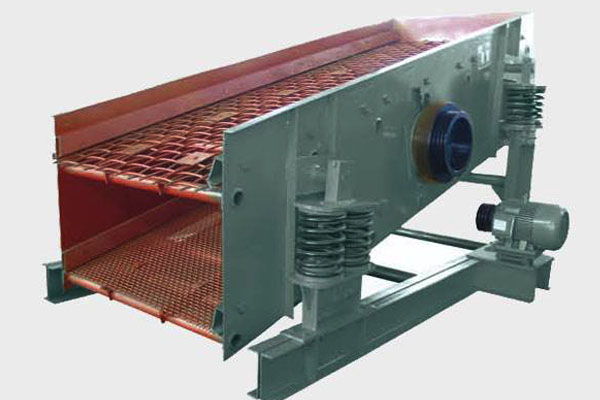

Circular Motion Vibrating Screen Manufacturers

Circular Motion Vibrating Screen

Mining Vibrating Motion Screen for Sale, Single or Multi-Deck, Full Model, Proven Technology. UHM Has 20+ Years of Experience in Vibrating Screen.

What is Circular Motion Vibrating Screen?

Circular vibrating screens operate using indirect excitation of the screen mesh. The entire screen frame is driven by unbalanced masses, which produce a circular vibrating motion.

The directionless vibrations of the circular vibrating system have a steep launch angle and the screen area must be further tilted in order to achieve a suitable transport speed. The optimum angle has been proven to be 15° to 30° in practice.

The Circular Motion Vibrating Screen is a versatile piece of equipment having the capacity to screen a wide range of minerals. It is widely used for segregating minerals such as aggregate, sand, coal, coke, slag, sinter, refractories, and urea and in various crushing and screening plants.

Circular Motion Vibrating Screens designed and manufactured by UHM are well-engineered equipment that proves their maximum reliability and efficiency in mineral screening.

Working Principle and Constructional Features

The circular vibration is usually generated by shafts with unbalance discs fixed on both sides, the shaft bearings being integrated in the sidewalls of the screen. The motors are mounted outside the screen tray on small platforms in the steel structure and are connected to the drive shafts by means of V-belts. To adapt screening performance and for optimum screen settings, the vibration amplitude can be adjusted by increasing or decreasing the unbalance weights. The speed can be varied just by changing the V-belt pulley.

The screen frame is an independent vibrating mass supported by a set of spring which is mounted on a rigid base frame. The mass mounted on the horizontal eccentric shaft close to the CG of the screen frame imparts oscillating circular motion due to centrifugal force. It generates a steep angle at which the particle flows forward on the screen deck which itself has a descending slope.

The feed material is then segregated where the oversize material flows to the discharge end on the screen deck and the undersize material falls through the opening below. With multiple deck arrangements, the crushed material is segregated according to size, for which suitable openings are provided on the screen deck.