Reciprocating Feeder

Reciprocating Plate Feeder

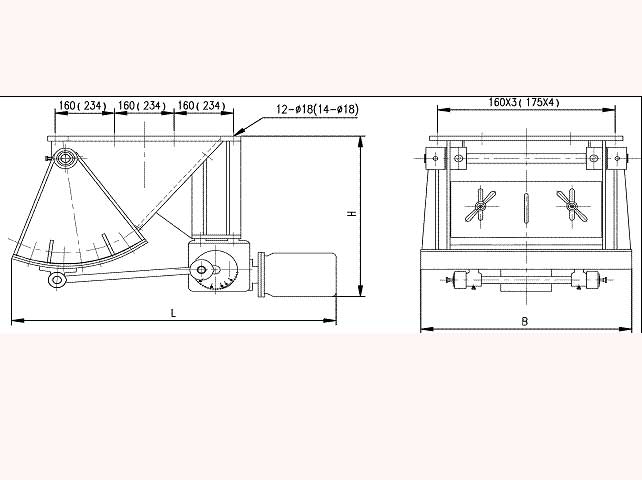

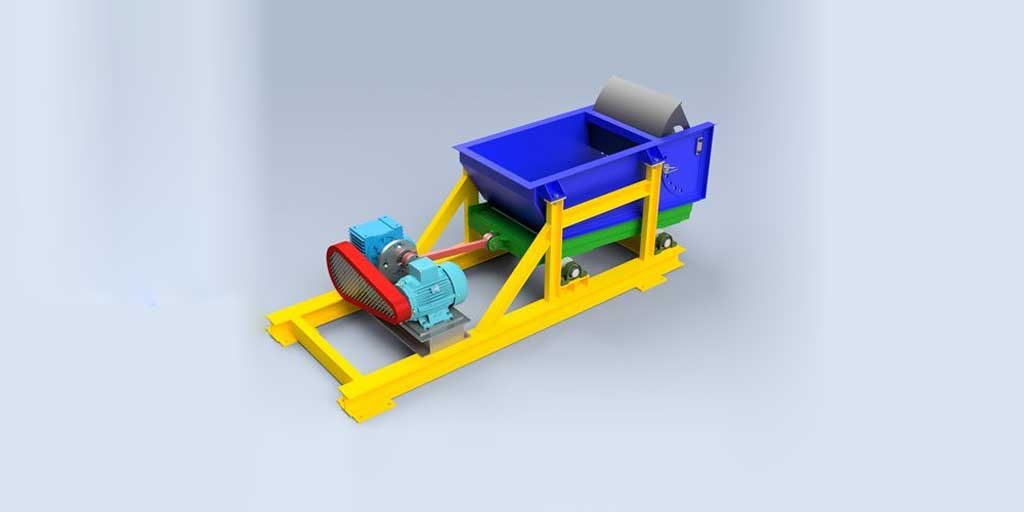

Reciprocating feeders (also called Reciprocating Plate Feeders) materials introduced by means of a hopper are unloaded from the feeder by a reciprocating motion. Back-and-forth motion frequency can be adjusted.. Consisting of a plate with reciprocating motion, sliding on rollers within guide rails, are provided with variable stroke adjustment, and a counterweight gate, in order to adapt the layer of extraction material, in order to tune the feed rate to the application.

Reciprocating Feeder

Reciprocating feeder (also called Reciprocating Plate Feeders) is a kind of feeding equipment that was used earlier in the storage tank discharge.

The reciprocating feeder produced by UHM is used for feeding coal or other loose granular materials with small abrasiveness and viscosity and unloads the materials in the storage bin or pit continuously and evenly to the transportation equipment or other equipment, vibrating screen equipment.

Read More: Guide to the Best Vibratory Feeder & Grizzly Feeder in 2023

Top 5 Advantages

- Reliable operation

- Long service life

- Lightweight

- Small size

- Convenient maintenance and maintenance

Top two Differences of Reciprocating Feeder

There are many types of reciprocating feeders.

- The common point of their structures is that they are all equipped with adjustable gates that can control the height of the material layer; At the bottom of the feeding, the chute is a feeding plate that moves back and forth.

- The difference is that the angle of the feeding plate is different. Generally, it is inclined downward at 5 degrees along the discharge direction and larger (less than the static accumulation angle of the material) and the horizontal type with an angle of zero.

The action of the feeding plate includes back-and-forth reciprocating, shaking, and swinging. The transmission mechanism of the reciprocating feeder is crank rotary type.

Application

The reciprocating feeder is suitable for beneficiation, coal, the chemical industry, and other departments. It transports granular materials from the storage tank to various types of receiving devices through the funnel. The pendulum feeder is not suitable for conveying dry powder or materials with too large particle size, otherwise, dust pollution and outlet blockage will occur.

8 Features

- Reciprocating vibratory feeder tray mounted on the standard steel channel fabricated frame at an inclination of 5 to10 degrees for better feeding results

- Adjustable reciprocating stroke length up to 300 mm. depending upon the size of lumps

- Substantial width of the tray to accommodate large lumps of material to be feed

- Tray and side walls lined with a wear-resistant plate for longer life

- The high-capacity model was designed with twin eccentric discs as well as the crank-lever mechanism

- A reciprocating feeder is ideal for sand, gravel, and recycling applications or in portable plants where the rugged durability of the feeder aids in the crusher discharge.

- The universal engineering reciprocating feeder is built in a range of sizes and types for shovel or dragline loading, ramp loading, or bulldozing to trap.

- It is available in varying widths and lengths to fit your specific application.

Overhaul and maintenance of reciprocating feeder

- Before the operation of the reciprocating feeder, there should be enough raw coal in the coal bunker to avoid direct impact on the floor when coal is loaded into the bunker.

- After continuous work, every month, check whether there are any abnormal phenomena such as the looseness of the machine parts. If any abnormal phenomenon occurs, it should be repaired immediately.

- The bottom lining plate of the reciprocating feeder in direct contact with the coal must be repaired or replaced if its thickness wear is greater than half of the original thickness.

- All rotating parts of the reciprocating feeder are required to be oiled once a month and inspected once a quarter to observe the damage of the bearings and seals and replace them in time if any problems are found.

- Maintenance of main components:

- Reducer: Check every six months, and at the same time clean the rolling bearing and the box or replace the lubricating oil.

- Motor: Carry out according to the inspection and maintenance requirements stipulated by the motor.

Attention to users: Lubricate the moving parts regularly, and check the operation of each part. If any abnormal situation is found, the cause should be found out and dealt with in time. If necessary, the manufacturer can be notified to deal with it; the gate should be closed when the empty warehouse is overhauled.

Technical Data

GZB Reciprocating Feeder

| Model |

Inlet L×M mm |

Eccentric stroke mm |

Number of swings times/min |

Maximum feed size mm |

shape |

Feeding capacity t/h |

Motor |

Weight kg |

||||

| L | B | H | Model |

Power kw |

Rotating speed r.p.m |

|||||||

| 300×300 | 300×300 | 0~90 | 46 | 30 | 1000 | 450 | 500 | 6.5 | Y80S-4 | 1.1 | 1390 | 272 |

| 400×400 | 400×400 | 0~170 | 46 | 35 | 1050 | 550 | 560 | 12 | Y90S-4 | 1.1 | 1400 | 558 |

| 600×600 | 600×600 | 0~200 | 46 | 50 | 1295 | 820 | 745 | 25 | Y90L-4 | 1.5 | 1400 | 613 |

GZB Reciprocating Feeder

| Model | K-0 | K-1 | K-2 | K-3 | K-4 | |||||||

| Feeding capacity(t/h) | Floor travel(mm) | Crank position | Anthracite | Bituminous coal | Anthracite | Bituminous coal | Anthracite | Bituminous coal | Anthracite | Bituminous coal | Anthracite | Bituminous coal |

| 200 | 4 | 100 | 90 | 150 | 135 | 225 | 200 | 330 | 300 | 590 | 530 | |

| 150 | 3 | 75 | 67 | 112 | 100 | 170 | 150 | 247 | 220 | 440 | 395 | |

| 100 | 2 | 50 | 45 | 75 | 68 | 133 | 100 | 165 | 150 | 295 | 268 | |

| 50 | 1 | 25 | 22 | 39 | 34 | 55 | 50 | 83 | 75 | 148 | 132 | |

| Crank speed(r/min) | 57 | 57 | 57 | 62 | 62 | |||||||

| Motor | Model | YB160M1-8 | YB160M1-8 | YB160M1-8 | YB160M1-6 | YB160M1-6 | ||||||

| (Y16M1-8) | (Y16M1-8) | (Y16M1-8) | (Y16M1-6) | (Y16M1-6) | ||||||||

| Power(kw) | 4 | 4 | 4 | 7.5 | 18.5 | |||||||

| Rotating speed(r/min) | 720 | 720 | 720 | 970 | 970 | |||||||

| Reducer | Model speed ratio | JZQ-350 | JZQ-350 | JZQ-350 | JZQ-400 | JZQ-500 | ||||||

| 12.64 | 12.64 | 12.64 | 15.75 | 15.75 | ||||||||

| Maximum Granularity Allowed(mm) | Moisture content below 10% | 250 | 350 | 400 | 500 | 700 | ||||||

| Moisture content above 10% | 200 | 300 | 350 | 450 | 550 | |||||||

| Weight(kg) | With hopper | 1127 | 1251 | 1481 | 1927 | 2737 | ||||||

| Without hopper | 1026 | 1144 | 1342 | 1735 | 2505 | |||||||

Read More: Feeder Wikipedia