drying plants fluid vibrating bed manufacturers

Industrial Dryers

Fluid Vibrating Bed

Experts in Vibrating Fluid Bed. Have 30+ Years of Experience in Vibrating Fluid Bed Dryers

Hot Sale High-Quality Industrial Dryers Fluid Vibrating Bed/Vibration Fluid Bed online.

What is Vibrating Fluid Bed Dryer

The Vibrating Fluid Bed Dryer and Cooler is a new fluidized and efficient drying and cooling device suitable for the drying of granular materials and powdery materials. It has the advantages of easy operation, energy-saving, and environmental protection.

In recent years, with the progress of vibration fluidized bed technology, vibration fluidized beds are used more and more widely for their unique advantages, especially in the sugar and food industry.

- Vibrating Fluid Bed Dryer: New fresh air from a fresh air room is heated then been blown into the lower chamber of the fluidizing bed and goes up through the mesh panel, and materials to be dried are fed into the vibrating bed, under the action of vibration and airflow the material is fully loosened and fluidized and move from the inlet to the outlet.

- Vibrating Fluid Bed Cooler: New fresh air from a fresh air room is cooled then been blown into the lower chamber of the fluidizing bed and goes up through the mesh panel, and materials to be cooled are fed into the vibrating bed, under the action of vibration and airflow the material is fully loosened and fluidized and move from the inlet to the outlet.

Vibrating fluid bed dryer Type

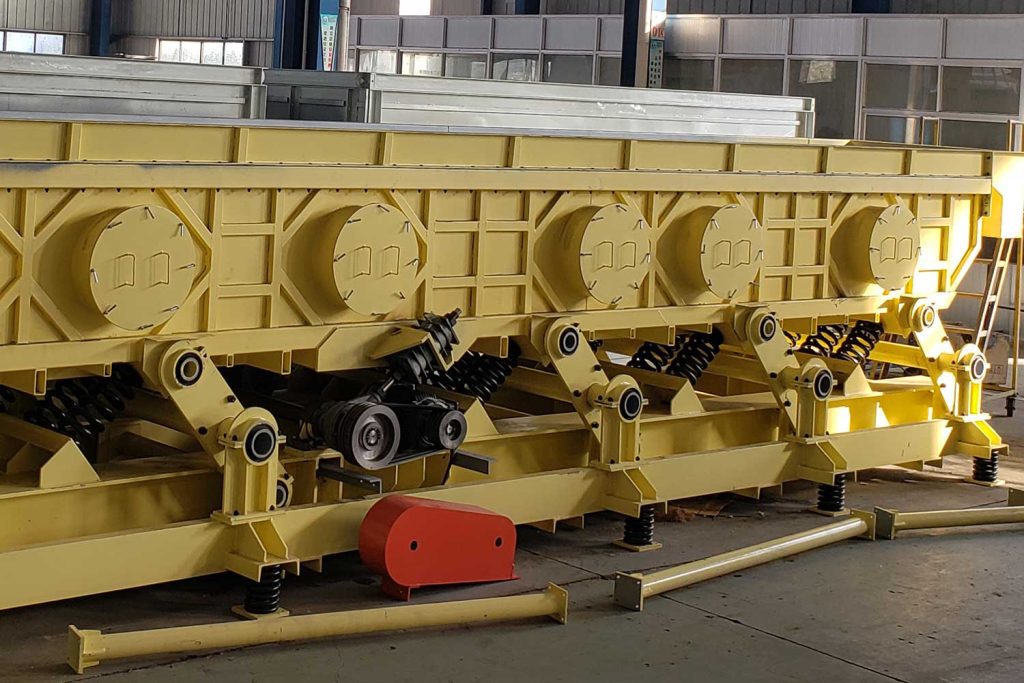

The vibrating fluid bed is divided into two types according to its vibration actuator, namely the ZLZ type with vibrating motors as vibration actuator and the ZLL type driven by a motor-driven eccentric shaft and elastic connecting rod ( Dynamically balanced vibratory conveyor ).

Both of these two types of vibrating fluidized bed can control the material walking speed by adjusting the vibration amplitude and vibration frequency, so as to control the residence time of the material in the fluidized bed to achieve the best dry or cooling effect and reduce the energy consumption, improve economic efficiency.

Vibrating fluid bed dryer

- Suitable for a wide range of materials of different particle sizes and gravity

- No damage to materials

- Drying and cooling in one is possible

- Smooth material flow and fully fluidization result in excellent drying and cooling efficiency

- Very easy control of temperature and moisture content

Structure of Vibrating Fluid Bed Dryer

The vibrating Fluid Bed Dryer & Cooler main structure is basically the same, divided into cover, box, air inlet, and observation windows.

Where the cover plate and between the bed breathable material constituting the fluidized chamber, with full access to the material to be dried and the moisture-absorbing materials in wet air from the exhaust outlet cited; set the viewing window on the cover, the material can be observed in real-time fluidized condition; width greater than 600mm on a bed cover generally use a separate support structure, the use of canvas or soft rubber sealing connection between the cover and the body.

Breathable panels below the box for the inflatable room, hot or cold air from entering the air inlet on the side, a certain pressure to make a uniform fluidized bed permeability through the gas distribution plate; due to non-normal operation, the material can fall into the box located plenum at the end of the discharge port discharge cleared.

Work Principle of Vibrating Fluid Bed Dryer

The system consists of a vibrating conveying & fluidizing bed as the main equipment.

New fresh air from a fresh air room is heated or cooled then been blown into the lower chamber of the fluidizing bed and goes up through the mesh panel, and materials to be dried or cooled are fed into the vibrating bed, under the action of vibration and airflow the material is fully loosened and fluidized and move from the inlet to the outlet.

Because the material is in a fully fluidized station, airflow can pass through every grain and take moisture away or heat or cool the material at high efficiency.

Exhausted air with dust and moisture is led into a cyclone (wet or dry) dust collector and then discharged into the atmosphere through a fan.

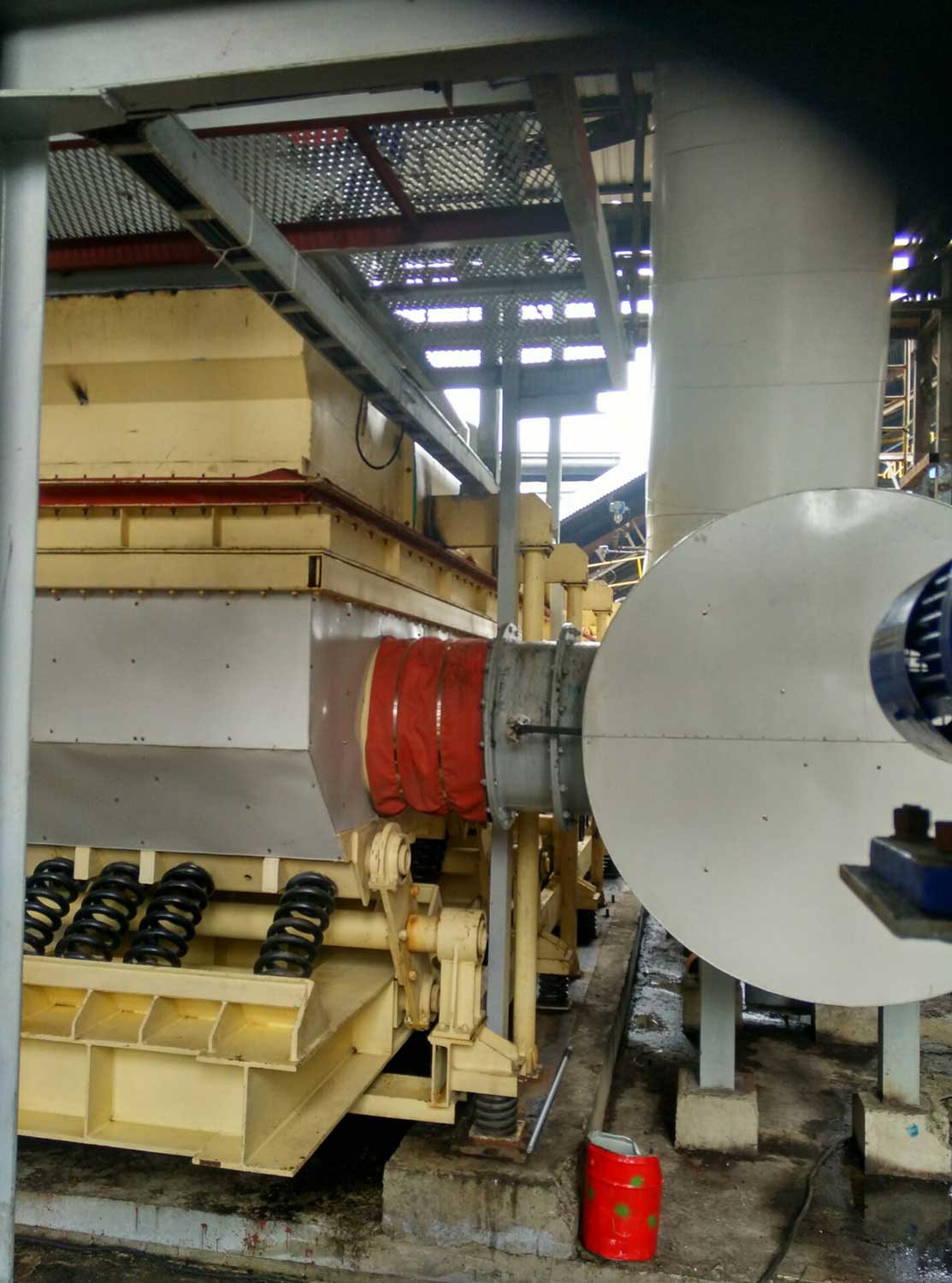

Photo of industrial dryers fluid vibrating bed