Linear Motion Vibrating Screen Manufacturers

Linear Vibrating Screen

What is the linear vibrating screen?

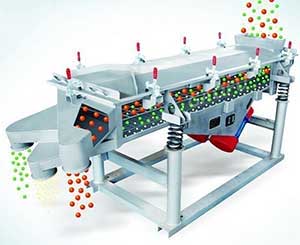

Linear vibrating screens are classic and general screening equipment, they use twin motors to shove a screening deck forward and then back. The ore is thrown up on the screening media surface and moves forward in a straight line, so as to achieve the purpose of screening and grading the ore. Linear vibrating screens have the characteristics of low energy consumption and high screening precision. The highest screening mesh is 400 mesh, which can screen out 7 kinds of materials with different particle sizes.

Principles of straight line vibration screen

When the linear vibrating screen is working, two rotating motors drive the eccentric block of the exciter to perform synchronously and reverse high-speed rotation through the V-shaped belt. The operation of the eccentric block generates a large amount of centrifugal force to make the linear screening decks reciprocate in a straight line in a direction perpendicular to the motor shaft( linear screening deck forward then back).

Linear screening decks use gravity that’s paired with the oscillating screening deck to drive the ore-sifting process, the material on the screening deck of the linear vibrating screen performs continuous throwing motion along a straight line under the action of its own gravity. During the collision between the material and the sieve(screen media), the particles smaller than the sieve pass through the sieve until all ore-containing material is sieved and classified. The linear vibrating screen is suitable for screening operations of granular materials with feed particle size < 10mm.

7 parts of the linear vibrating screen structure

The main structures of the linear vibration screen include a screen body, screen frames, screen media, vibration motors, motor bases, springs, materials feed and unload ports, and other components.

- Vibrating screen body: The vibrating screen body is the main component of a linear vibrating sieve, it is made of welding from steel plates of different thicknesses, and has a certain strength and rigidity.

- Vibrating screen frame: The material of the linear vibration screen frame is different (carbon steel or stainless steel). The sieve frame is mainly used to keep the screen flat and achieve normal screening.

- Sieve media: Mainly there are different types of silk nets, metal sieve nets, and synthetic fiber networks, and respectively meet the food industry, chemical industry, and mining applications.

- Motor: Vibration source for vibrating screen. It can be divided into horizontal vibration motor and vertical vibration motor.

- Motor base: Install the vibration motor to ensure that the position of the motor is fixed.

- Spring: Reduce the pressure of vibration screening to the base. When installation, the spring is vertically on the ground to support the protective effect on the rack.

- The ore feed port and unload port: It usually needs to be customized according to the feeding port and the material port to facilitate the installation and use of the equipment.

Features of linear vibration sieve

- Quickly replace the screen media, quickly tighten it;

- High efficiency, low noise;

- The material screening is high, and the processing volume is large;

- Linear vibration can also achieve long-distance conveying materials at the same time while screening;

- Control the screen rate and production efficiency by changing the length and inclination of the sieve;

- It is convenient to design different sizes and structures according to the production site.

Application of linear vibrating screen

Linear vibrating screens are used in a variety of ways, including screening bulk materials, separating agglomerates of large particles, and conveying between various processes. The range of applications is very wide and can be used for:

- Steel Plant

- Coal mining

- Foundry

- Sand and gravel aggregate plant

- Cement

- Glass and ceramics

- Dood and feed

- Municipal and construction waste recycling

- Production of wood chips, pellets, fiberboard

- Chemical and Plastic Production

- Mine tailings, etc.