Circular Motion Vibrating Screen Manufacturers

YK Type

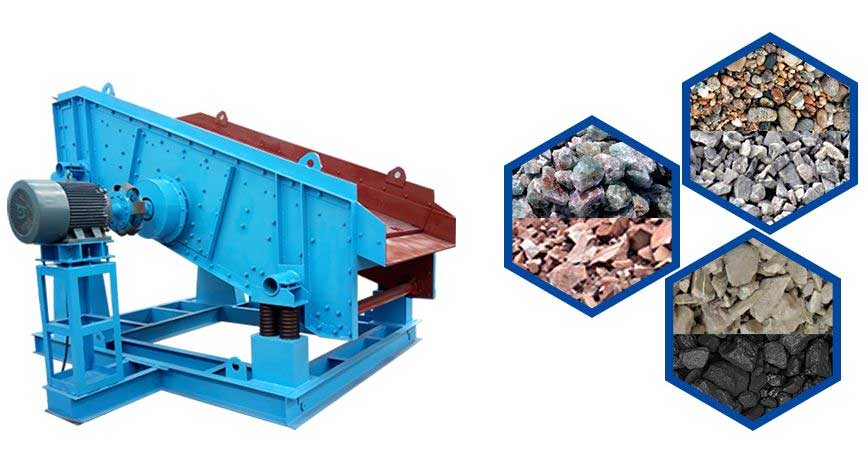

Circular Motion Vibrating Screen

UHM YK vibrating screen can be adjusted, flow line of sieve is long, multi-layer screening, screening of each grade is clear, efficiency is high.

YK series circular motion vibrating screen

The YK series circular motion vibrating screen uses the inner eccentric shaft as the exciting force, and uses the motor to drive the eccentric shaft to rotate, and then the linked vibrating screen makes a circular motion track of up, front, down and back, so that the screened materials can evenly slip through the screen quickly. And complete the screening work.

The amplitude of YK series circular motion vibrating screen manufactured by UHM can be adjusted, the flow line of the material sieve is long, multi-layer screening, the screening of each grade is clear, and the screening efficiency is high.

Application of YK series circular motion vibrating screen

YK series circular motion vibrating screens are suitable for screening sand and gravel in quarries, and can also be used for product classification in coal preparation, mineral processing, building materials, electric power and chemical industries.

Working principle of YK series circular motion vibrating screen

YK series circular motion vibrating screen mainly consists of screen box, screen mesh, vibrator, damping spring device, chassis and so on. A cylinder-type eccentric shaft exciter and an eccentric block are used to adjust the amplitude. The vibrator is installed on the side plate of the screen box, and is driven by a motor to rotate through a V-belt to generate centrifugal inertial force, forcing the screen box to vibrate. The side plate of the screen machine is made of steel plate, and the side plate is connected with the beam and the base of the vibrator with high-strength bolts or ring groove rivets.

The motor drives the eccentric block of the exciter to rotate at high speed through the V-belt. The running eccentric block produces a large centrifugal force, which excites the screen box to produce a circular motion with a certain amplitude. The material on the screen receives the impulse transmitted by the screen box on the inclined screen surface and produces continuous throwing motion. The process of the material meeting the screen surface In the middle, the particles smaller than the sieve are sieved to achieve classification.

Product Features and Technical Advantages of YK Series Circular Motion Vibrating Screen

The block eccentricity is used as the exciting force, and the exciting force is strong;

The screen beam and the screen box are connected by high-strength bolts without welding;

The vibrating screen has a simple structure and is easy to maintain;

Using tire coupling, flexible connection, stable operation;

High screening efficiency, large processing capacity and long service life

Specification of YK series circular motion vibrating screen

| Type | Layers | Screen area (m2) | Mesh size (mm) | Feeding size (mm) | Apacity (m3/h) | Vibrating Frequency (r/min) | Double Amplitude (mm) | Motor (kw) | Overall dimensions (mm) | Weight kg | Angle | Screen size (mm) |

| YK1020 | 1 | 2.0 | 3-30 | 100 | 5-38 | 960 | 8 | 5.5 | 2160*1770*1675 | 1400 | 20° | 980*2050 |

| 2YK1020 | 2 | 2.0 | 3-30 | 100 | 5-38 | 960 | 8 | 5.5 | 2160*1170*1920 | 1950 | 20° | 980*2050 |

| YK1230 | 1 | 3.2 | 3-50 | 200 | 7.5-78 | 960 | 8 | 5.5 | 3073*2030*1611 | 1750 | 20° | 1200*3000 |

| 2YK1230 | 2 | 3.2 | 3-50 | 200 | 7.5-78 | 960 | 8 | 5.5 | 3122*2050*2247 | 2375 | 20° | 1200*3000 |

| 3YK1230 | 3 | 3.6 | 5-50 | 200 | 15-86.3 | 970 | 8 | 7.5 | 3200*2145*2300 | 2700 | 20° | 1200*3050 |

| YK1535 | 1 | 4.7 | 5-50 | 200 | 20-125 | 970 | 8 | 11 | 4684*3971*2404 | 3270 | 20° | 1500*3500 |

| 3YK1535 | 3 | 5.25 | 5-50 | 400 | 21-125 | 970 | 8 | 15 | 4719*3106*3273 | 5710 | 20° | 1500*3500 |

| YK1545 | 1 | 6.75 | 5-50 | 400 | 27.25-161 | 970 | 8 | 11 | 4600*2911*2076 | 3900 | 20° | 1500*4500 |

| 2YK1545 | 2 | 6.75 | 5-50 | 400 | 22-150 | 970 | 8 | 15 | 4650*2820*3500 | 4370 | 20° | 1500*4500 |

| 3YK1545 | 3 | 6.75 | 5-50 | 400 | 22-150 | 970 | 8 | 15 | 4710*3035*3232 | 5800 | 20° | 1500*4500 |

| 3YK1548 | 3 | 7.2 | 5-50 | 400 | 22.5-162 | 970 | 8 | 15 | 5210*3035*3800 | 5800 | 20° | 1500*4800 |

| 2YK1848 | 2 | 8.64 | 5-100 | 400 | 56-330 | 970 | 8 | 15 | 4802*3035*3232 | 6189 | 20° | 1830*4880 |

| 3YK1848 | 3 | 8.64 | 5-400 | 400 | 56-330 | 970 | 8 | 18.5 | 5027*350*4150 | 6600 | 20° | 1880*4800 |

| 2YK1854 | 2 | 9.72 | 5-100 | 400 | 63-420 | 970 | 8 | 18.5 | 6000*3350*3500 | 8050 | 20° | 1800*5400 |

| 3YK1854 | 3 | 9.72 | 5-100 | 400 | 63-380 | 970 | 8 | 22 | 6200*3350*4100 | 8640 | 20° | 1800*5400 |

| YK2154 | 1 | 11.34 | 5-100 | 400 | 73-580 | 970 | 8 | 18.5 | 5400*3350*3450 | 8200 | 20° | 2100*5400 |

| 2YK2154 | 2 | 11.34 | 5-100 | 400 | 73-580 | 970 | 8 | 22 | 5600*3650*3600 | 9710 | 20° | 2100*5400 |

| 3YK2154 | 3 | 11.64 | 5-100 | 400 | 56-520 | 970 | 8 | 22 | 5890*3650*4100 | 11000 | 20° | 2100*5400 |

| YK2160 | 1 | 12.6 | 5-100 | 400 | 90-680 | 970 | 8 | 18.5 | 6375*3821*3500 | 8500 | 20° | 2100*6000 |

| 2YK2160 | 2 | 12.6 | 5-100 | 400 | 90-640 | 970 | 8 | 22 | 6500*3950*3550 | 9800 | 20° | 2100*6000 |

| 3YK2160 | 3 | 12.6 | 5-100 | 400 | 80-600 | 970 | 8 | 30 | 6720*4150*4198 | 11500 | 20° | 2100*6000 |

| 2YK2454 | 1 | 12.9 | 6-150 | 400 | 83-760 | 980 | 8 | 30 | 5775*4550*3530 | 11500 | 20° | 2400*5400 |

| 2YK2454 | 2 | 12.9 | 6-150 | 400 | 83-760 | 980 | 8 | 30 | 5900*4550*3580 | 13000 | 20° | 2400*5400 |

| YK2460 | 3 | 14.4 | 6-150 | 400 | 110-800 | 980 | 8 | 30 | 6375*4550*3730 | 11580 | 20° | 2400*6000 |

| 2YK2460 | 1 | 14.4 | 6-150 | 400 | 110-800 | 980 | 8 | 30 | 6500*4550*3780 | 13400 | 20° | 2400*6000 |

| 3YK2460 | 2 | 14.4 | 6-150 | 400 | 110-800 | 980 | 8 | 37 | 6720*4615*4198 | 15590 | 20° | 2400*6000 |

Read More: Vibrating Screen Wikipedia

Notice

YK series circular motion vibrating screens are divided into single-layer, double-layer and three-layer. The screen structure includes woven mesh, perforated screen plate, polyurethane screen plate, etc. Users can choose according to their needs and should be specified when ordering.

The motor of YK series circular motion vibrating screen can be installed on the left or right side, please specify when ordering, if there is no instruction, then supply according to the installation drawing.

The foundation bolts of YK series circular motion vibrating screen are prepared by the user.

Read More: Guide to the Best Vibrating Screen in 2023