vibrating conveyor manufacturers

THREE-MASS

Vibrating Conveyor

Experts in Conveyor Vibration System. Have 30+ Years of Experience in Vibration Conveyor Systems.

Hot Sale High-Quality 3-mass Vibrating Conveyor Online.

Three-Mass Resonance Vibratory Conveyor

dynamically balanced vibratory conveyor

PSL dynamically balanced vibratory conveyor (Three-Mass Resonance Vibratory Conveyor), has very little reaction force is transmitted to the ground.

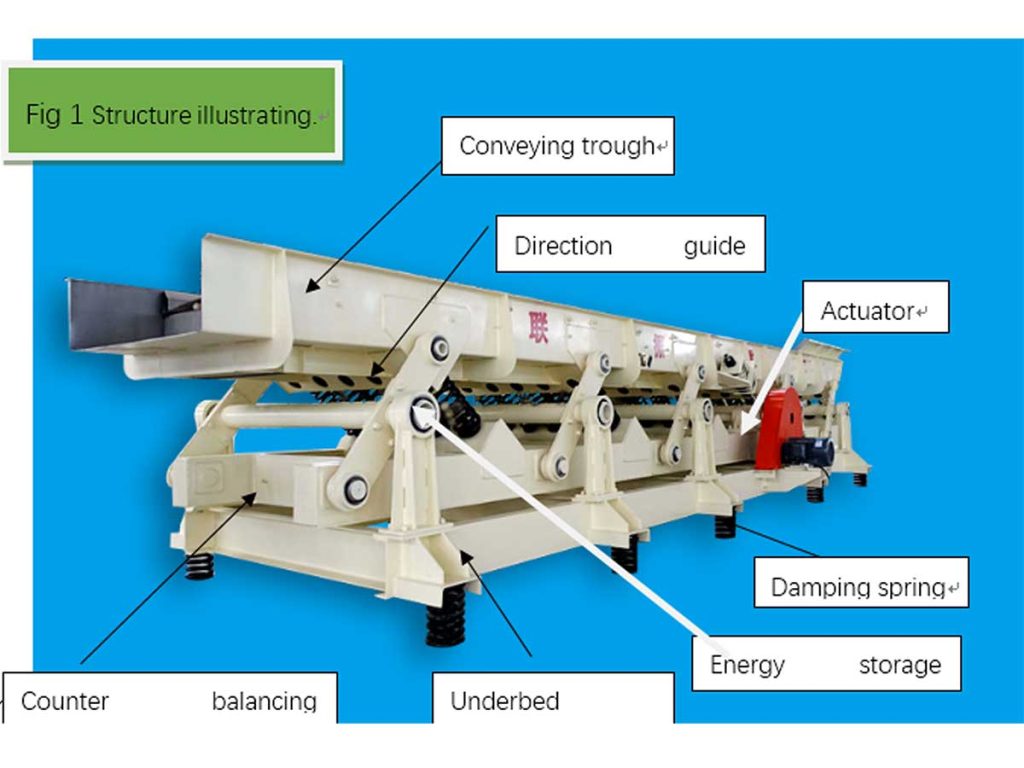

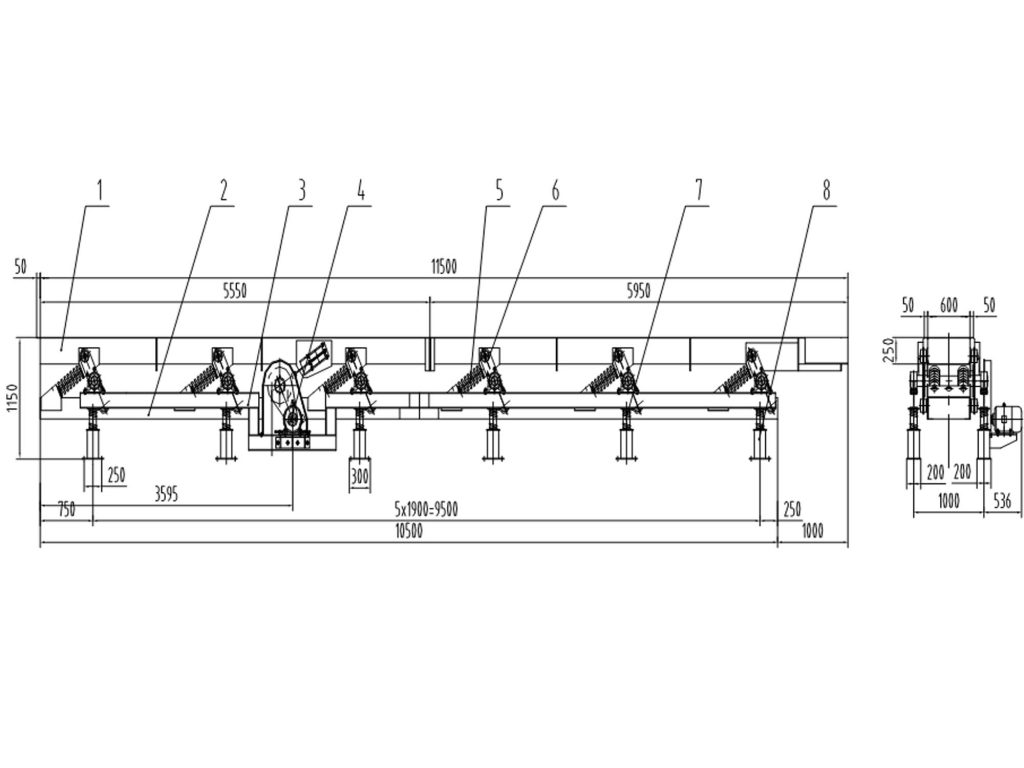

structure

Dynamically balanced vibrating conveyor use the fully balanced system. The upper and lower troughs are coupled together by springs, and mounted at the central point of the coupling on a fixed frame. Both troughs are vibrated by means of motor-driven eccentric crank action and spring-generated resonant vibration.

Advantages

PSL Dynamically balanced vibratory conveyor is developed on the basis of the plastid resonance type of a new type of vibrating conveyor, besides has the advantages of the plastid resonance type, the most prominent advantage is passed to the base of inertial vibration (dynamic load) is very small, low noise, suitable for long, wide groove width of transport requirements, when the floor surface or on steel structure installation with other type of vibrating conveyor incomparable shock absorption edge.

Features of Three-Mass Vibratory Conveyor

- 3-Mass Vibrating Conveyor is suitable to be applied in vibration-sensitive situations such as weighing packing machine area, upstairs, steel structure platform, high bridge way etc.

- Double trough is available and can convey materials simultaneously.

- In case of the height of inlet is limited, lower conveying trough can be designed to replace balancing structure.

- Leaf plate can be placed in the trough to reinforce cooling and loosening wet materials such as wet sugar.

Advantage of Three-Mass Vibratory Conveyor System

- The inertial vibration force (dynamic load) transmitted to the foundation is very small and low in noise

- Suitable for long-distance, wide groove width conveying requirements

- Unmatched shock absorption advantages of other types of vibrating conveyors when installed on floor slabs or steel frame supports

- If the balance body is used as the transport groove body, the upper and lower grooves can be transported at the same time, and the effect of using two vibrating conveyors can be produced without increasing equipment and space.

- A screen is installed in the conveying groove to realize the classification of the material while conveying.

Structure of Three-Mass Vibration Conveyor

Dynamically balanced vibratory conveyor, with unique structure as illustrated in Fig.1, the upper trough is coupled with the counterbalancing structure with direction guide beams and energy storage coil springs, they are supported at the center of the guide beam on the underbed structure.

The reacting force of the upper trough is fully balanced by the lower counter balancing structure, in case the unbalanced reacting force is caused by materials on the trough or any other reason, it can be re-balanced by the under bed structure and damper springs.

- Conveyor through

- Balancing stand

- Underbed

- Eccentric connecting rod drive

- Resonant spring;

- Elastic pendulum device

- Damping spring

- Damping seat

Principle of Three-Mass Vibratiing Conveyor

A fully balanced type vibration conveyor adopts unique elastic support, makes a delivery tub, and balances the body to form a quality complete balance of double plastid resonance system, two plasmids through swinging rod coupling resonance spiral springs and elastic guide, conveying groove under the action of the vibrator, and balance the body form a resonance system, the inertia vibration resonance system to produce the basic offset in the system;

Equipment support base plate through the spring vibration isolation system-based connection and installation can change because of material flow in the tub again to reduce the unbalanced vibration, thus equipment is the basis of the dynamic load is very small.

Application

This dynamically balanced vibratory conveyor is suitable for many industries including biomass, recycling, pellet manufacturing, sawmill, plywood, OSB, food processing, and agricultural industries.

Specification

| Model | Capacity (t/h) | Width (mm) | Length (m)→ | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 15 | 18 | 20 | 25 | 28 |

| PSL300 | 18 | 300 | KW→ | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 5.5 |

| PSL400 | 30 | 400 | KW→ | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 5.5 | 7.5 |

| PSL600 | 50 | 600 | KW→ | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 |

| PSL800 | 70 | 800 | KW→ | 1.5 | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 |

| PSL1000 | 90 | 1000 | KW→ | 2.2 | 2.2 | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 |

| PSL1200 | 110 | 1200 | KW→ | 2.2 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 7.5×2 |

| PSL1500 | 140 | 1500 | KW→ | 3.7 | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 |

| PSL1800 | 160 | 1800 | KW→ | 3.7 | 3.7 | 5.5 | 5.5 | 7.5 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 | 11×2 |

| PSL2000 | 180 | 2000 | KW→ | 3.7 | 5.5 | 5.5 | 3.7×2 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 | 11×2 | 11×2 |

| PSL2400 | 220 | 2400 | KW→ | 5.5 | 5.5 | 3.7×2 | 5.5×2 | 5.5×2 | 7.5×2 | 7.5×2 | 11×2 | 11×2 | 11×2 | 15×2 | 15×2 |

How to use the PSL Vibrating conveyor?

Commissioning

After the installation and commissioning of the vibrating conveyor, the no-load continuous test run of not less than 8 hours should be carried out.

Pay attention to the changes in conveyor amplitude, working current, and noise during operation.

After confirming that there is no abnormality, it can be put into normal operation.

Productivity adjustment

The Dynamically balanced vibratory conveyor is a fixed-frequency fixed-width vibrating conveying device.

If the productivity of the conveyor is adjusted, the opening of the silo gate can be adjusted to change the feeding amount or change the eccentric position of the driving device. To achieve the purpose of adjusting the productivity of the conveyor.

Maintain of the PSL Vibrating conveyor

- During the use of the vibrating conveyor, it is necessary to regularly apply grease (No. 3 calcium-based grease) to the bearing housing and the connecting rod bearing of the drive mechanism.

- Continuous operation is repeated every two weeks, and non-continuous operation is filled once a month.

- Always check the fastening of each fastener and replace consumables (plate springs, coil springs, rubber springs and fasteners) for long-term damage (fatigue, defects, aging wear).

- It is strictly forbidden to operate with illness

- Pay attention to check the temperature rise (feel) of the bearing part of the drive mechanism

- If an abnormality is found, it must be stopped immediately for inspection.

Notes

Delivery amount calculated in accordance with the calculation of transport sand (bulk density of 1.6t / m3, the moisture content of 5%) level.

Conveyor installation of tank closures, liner and bulk density of the material at different power delivery to be recalculated.

Transmission distance over 15 meters, using segmented structure, site assembly connection.