GZ Electromagnetic

Vibratory Feeder

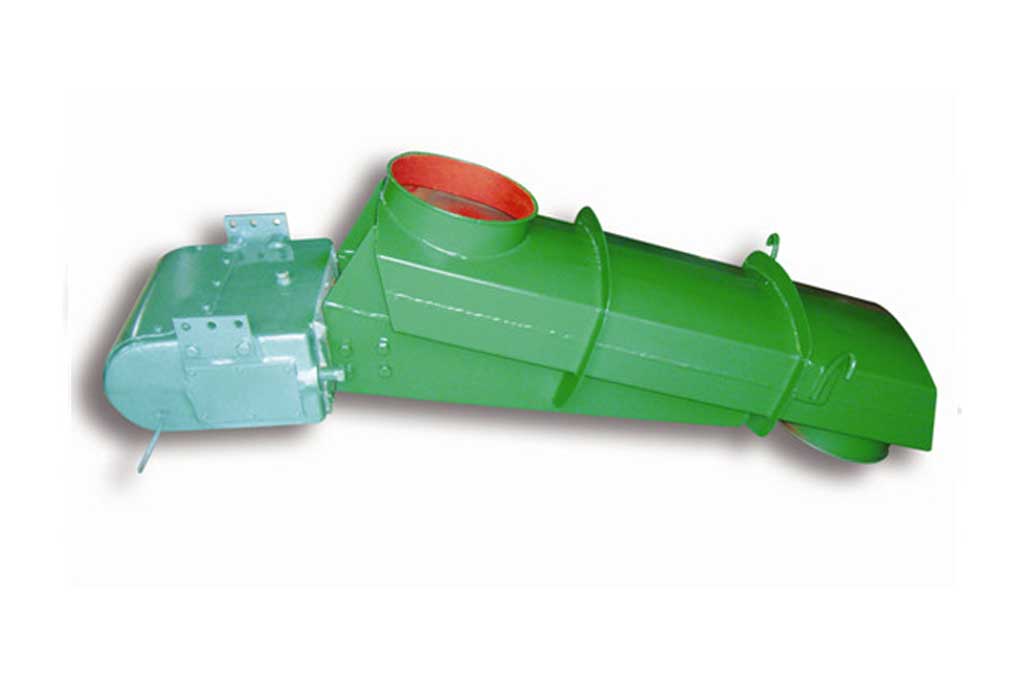

GZ Series Electromagnetic Vibratory Feeder

GZ series electromagnetic vibratory feeder is suitable for continuous production requirements. The GZ electromagnetic vibratory feeder can be widely used in cement, mining, metallurgy, coal yard, chemical industry, infrastructure, wharf, pharmaceutical, tea processing, porcelain industry, and other industrial sectors. In the production process, non-viscous granular or powder materials can be quantitatively, uniformly, and continuously sent to the receiving device from the storage bin or hopper.

Read More: Guide to the Best Vibratory Feeder & Grizzly Feeder in 2023

Four Features of GZ Series Electromagnetic Vibratory Feeder

- Electric control adopts a thyristor half-wave rectification circuit. The feeding amount can be adjusted steplessly, and it can be used in the production process of automatic control to realize production automation.

- The electromagnetic vibrating feeder has no rotating parts, no lubrication, a simple structure, and convenient maintenance.

- The material is slightly thrown, and the wear of the chute is small.

- The electromagnetic vibrating feeder adopts the trough made of alloy steel plate, which is suitable for conveying high temperature, severely worn and corrosive materials, etc.

Equipment Selection

| Type | Productivity Calculation Test Weight(T/m3) | Application |

| Basics | 1.6 | Material feeding without special requirements |

| up mode | 1.6 | Installation and use when the configuration space is unavoidable, others are the same as the basic type |

| Closed | 1.6 | Feeding of fragile particles, large dust, and volatile materials |

| Light groove | 1.0 | The feed of light material with small specific gravity |

| Flat Groove | Given according to coal blending and coal preparation conditions | Even feeding of the thin material layer |

| Wide groove | Given according to coal blending and coal preparation conditions | It is mainly used for coal preparation, and can also be used for feeding to screening equipment |

- When the actual capacity is greater or less than the above-calculated capacity, the production rate shall be converted according to the actual material capacity.

- For materials with a particle size of less than 1mm, the conveying speed will drop, and wet and viscous materials with water content greater than 10% cannot be conveyed normally. If the thickness of the material layer exceeds a certain value, it will hinder normal feeding. It is recommended that H=(1/3~1/4) tank height.

- For products with special requirements and specifications, our factory can specially design and manufacture them.

Read More: Feeder Wikipedia

Technical Parameters

| Type | Model | productivity(t/h) | Feed size(mm) | Double amplitude(mm) |

Vibration frequency (times/minute) |

Voltage (v) |

Electric current(A) |

Active power (kw) |

Weight (kg) |

||

| Level | -10° | Working current | Indicates the current | ||||||||

| Basic | GZ1 | 5 | 7 | 50 | 1.75 | 3000 | 220 | 1.34 | 1.0 | 0.06 | 77 |

| GZ2 | 10 | 14 | 50 | 3.0 | 2.3 | 0.15 | 151 | ||||

| GZ3 | 25 | 35 | 75 | 4.6 | 3.8 | 0.20 | 233 | ||||

| GZ4 | 50 | 70 | 100 | 8.4 | 7.0 | 0.45 | 460 | ||||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 668 | ||||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1271 | ||

| GZ7 | 250 | 350 | 300 | 24.6 | 20 | 2.5 | 1920 | ||||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4.0 | 3040 | ||||

| GZ9 | 600 | 840 | 500 | 47.6 | 38.6 | 5.5 | 3750 | ||||

| GZ10 | 750 | 1050 | 500 | 39.4×2 | 32×2 | 4.0×2 | 6491 | ||||

| GZ11 | 1000 | 1400 | 500 | 47.6×2 | 38.6×2 | 5.5×2 | 7680 | ||||

| up mode | GZ3S | 25 | 35 | 75 | 1.75 | 220 | 4.6 | 3.8 | 0.20 | 242 | |

| GZ4S | 50 | 70 | 100 | 8.4 | 7.0 | 0.45 | 457 | ||||

| GZ5S | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | 666 | ||||

| GZ6S | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1246 | ||

| GZ7S | 250 | 350 | 250 | 24.6 | 20 | 2.5 | 1963 | ||||

| GZ8S | 400 | 560 | 300 | 39.4 | 32 | 4.0 | 3306 | ||||

| Closed | GZ1F | 4 | 5.6 | 40 | 1.75 | 220 | 1.34 | 1.0 | 0.06 | 78 | |

| GZ2F | 8 | 11.2 | 40 | 3.0 | 2.3 | 0.15 | 154 | ||||

| GZ3F | 20 | 28 | 60 | 4.6 | 3.8 | 0.20 | 247 | ||||

| GZ4F | 40 | 50 | 60 | 8.4 | 7.0 | 0.45 | 464 | ||||

| GZ5F | 80 | 112 | 80 | 12.7 | 10.6 | 0.65 | 668 | ||||

| GZ6F | 120 | 168 | 80 | 16.4 | 13.3 | 1.5 | 1278 | ||||

| Light groove | GZ5Q | 100 | 140 | 200 | 1.5 | 380 | 12.7 | 10.6 | 0.65 | 653 | |

| GZ6Q | 150 | 200 | 250 | 1.75 | 220 | 16.4 | 13.3 | 1.5 | 1326 | ||

| GZ7Q | 250 | 350 | 300 | 1.5 | 380 | 24.6 | 20 | 2.5 | 1992 | ||

| GZ8Q | 400 | 560 | 350 | 39.4 | 32 | 4.0 | 3046 | ||||

| Flat Groove | GZ5P | 50 | 140 | 100 | 1.75 | 220 | 12.7 | 10.6 | 0.65 | 633 | |

| GZ6P | 75 | 210 | 300 | 1.5 | 380 | 16.4 | 13.3 | 1.5 | 1238 | ||

| GZ7P | 125 | 350 | 350 | 24.6 | 20 | 2.5 | 1858 | ||||

| Wide groove | GZ5K1 | 200 | 100 | 1.5 | 220 | 12.7×2 | 10.6×2 | 0.65×2 | 1212 | ||

| GZ5K2 | 240 | 100 | 1343 | ||||||||

| GZ5K | 27 | 100 | 1376 | ||||||||

Four structural features

GZ electromagnetic vibrating feeder is mainly composed of a trough, electromagnetic exciter, damping spring, control box, etc. The main structural features are:

- Material trough: welded by wear-resistant steel plate, with high strength and rigidity, mainly used for material transportation;

- Electromagnetic exciter: It is mainly composed of an electromagnet (iron core and coil), armature, and main vibration spring installed between the two. It is the excitation source of vibration, and the size of its excitation force can be adjusted through the control device;

- Damping spring: The damping spring is a steel coil spring with high reliability and stability;

- Control box: mainly used to adjust the level of the rectified voltage to realize the regulation of the exciting force