Motor

Vibratory Feeder

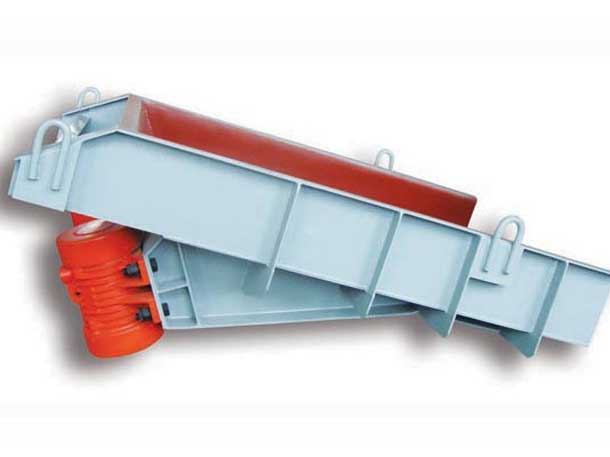

Practical and easy to use, UHM single-mass dual motor vibratory feeders provide linear motion and are a practical option for many applications.

Motor Vibratory Feeder

In the production process, the Motor Vibratory Feeder can uniformly, regularly, and continuously feed the bulk and granular materials from the storage bin to the receiving device, such as crushing, coal preparation, screening, transportation, packaging machinery, and other materials, batching, etc., in the sand and gravel production line, it can continuously and evenly feed the crushing machinery, and coarsely screen the materials.

The Motor Vibratory Feeder has the characteristics of small size, lightweight, simple structure, convenient installation and maintenance, large feeding volume, high efficiency, low noise, and low power consumption. The Motor Vibratory Feeder is widely used in metallurgy, coal mines, mineral processing, building materials, chemicals, abrasives, screening combined equipment, and other industries.

- Stable vibration and reliable operation;

- Convenient and stable adjustment;

- Vibration motor as vibration source, low noise, and small power consumption;

- Simple structure and easy maintenance。

Principle

Motor vibration feeder Through driving the vibrating motor or two motors, it engenders a specific exciting force, which drives the vibrating frame to make periodic linear and reciprocal vibrations along the inclined direction. When the vibrating accelerated speed of the vertical component of the vibrating frame is larger than gravity’s accelerated speed, materials are thrown up and move forward along a parabolic path, and throwing up and falling down are completed in a flash.

- Using the self-synchronization principle of a special vibration motor, the starting is quick, the work is stable, and the parking is stable.

- The material continuously jumps forward according to the parabola trajectory, so the feed groove wears less.

- Since the flow can be changed and opened and closed instantaneously, the feed amount has high precision.

Read More: Guide to the Best Vibratory Feeder & Grizzly Feeder in 2023

Six Features of Motor Vibratory Feeder

GZG series motor vibratory feeder can adjust the exciting force to change and control the flow rate during use and is generally equipped with two constant-speed vibrating motors. It is also possible to choose a frequency conversion motor vibrating feeder according to the needs, equipped with two frequency conversion vibration motors, and the frequency converter can be used to adjust the vibration frequency, thereby adjusting the feeding amount.

- Stable vibration, reliable operation, and long service life;

- The exciting force can be adjusted, the flow rate can be changed and controlled at any time, and the adjustment is convenient and stable;

- The vibration motor of the GZG linear vibrating feeder is the excitation source, with low noise, low power consumption, good adjustment performance, and no rushing phenomenon;

- Simple structure, reliable operation, convenient adjustment, and installation;

- Lightweight, small size, easy maintenance;

- When the closed structure body is used, dust pollution can be prevented.

How to Choosing the right Motor Vibrating Feeder

Five Tips of Productivity

The productivity of the GZG series motor vibrating feeder is based on river sand as the standard material (heap specific gravity is 1.6t/m3).

- When the specific gravity of the material pile is greater than 1.6t/m3, its output can be selected according to the rated value;

- When the heap specific gravity of the material is 1.2-1.6t/m3, its output can reach 0.9-1.0 times of the rated output;

- When the specific gravity of the material pile is 0.8-1.2t/m3, its output can reach 0.8-0.9 times of the rated value;

- When the specific gravity of the material pile is less than .6t/m3, the thickness of the material layer must be appropriately increased to increase the output;

- For materials that are difficult to convey by vibrating feeders (such as talcum powder, titanium dioxide, white mud, fabrics, clay, etc.), and hydrophilic materials with high water content, the output should be determined according to the test. If necessary, install the trough with an appropriate inclination (generally 10-15° downward) to increase the feeding amount.

Control box

The GZG series motor vibratory feeder is equipped with a reverse brake control box, which can make the vibrating feeder stop quickly when it is stopped so that the vibrating feeder can quickly pass through the resonance area, and avoid damage to the machine caused by excessive amplitude.

The control box has over-current, over-voltage, and out-of-equity protection functions. According to the process requirements, functions such as energy-consuming braking, fast and slow feeding, remote control, and stepless frequency conversion speed regulation can be added. Please specify when ordering.

Conditions of use of vibrating feeder

- The ambient temperature does not exceed +40°C;

- When the ambient temperature is 20±5°C, the relative humidity of the surrounding medium is not greater than 85%;

- There is no explosive hazardous medium around;

- There is no serious corrosion or medium affecting the electrical insulation around.

Considering the limitation of space when selecting the model, there are two ways to install the motor, one is the installation on both sides of the motor, and the other is the rear installation of the motor.

Read More: Feeder Wikipedia

Main technical parameters of the motor vibrating feeder

|

Model |

Groove size B×L×H (cm) |

Feed (t/h) | Maximum feed size(mm) | Double amplitude(mm) | Vibration frequency (times/minute) |

Rated voltage (v) |

rated current (a) |

Power (kw) |

Weight (kg) |

|

| Horizontal angle | -10° | |||||||||

| GZG30-80 | 30×80×15 | 30 | 40 | 100 | 4 | 1450 | 380 | 0.87 | 2×0.25 | 180 |

| GZG40-90 | 40×90×20 | 40 | 50 | 100 | 4 | 0.87 | 2×0.25 | 205 | ||

| GZG50-100 | 50×10×20 | 60 | 80 | 150 | 4 | 0.87 | 2×0.25 | 230 | ||

| GZG60-100 | 60×100×20 | 100 | 150 | 200 | 4 | 1.76 | 2×0.55 | 370 | ||

| GZG70-100 | 70×100×25 | 120 | 170 | 200 | 4 | 1.76 | 2×0.55 | 390 | ||

| GZG80-120 | 80×120×25 | 160 | 230 | 250 | 4 | 2.17 | 2×0.75 | 560 | ||

| GZG90-150 | 90×150×25 | 180 | 250 | 250 | 4 | 2.17 | 2×0.75 | 610 | ||

| GZG100-150 | 100×150×25 | 270 | 380 | 300 | 4 | 3.18 | 2×1.10 | 760 | ||

| GZG110-150 | 110×150×25 | 300 | 420 | 300 | 4 | 3.18 | 2×1.10 | 840 | ||

| GZG125-160 | 125×160×30 | 450 | 650 | 350 | 4 | 3.80 | 2×1.50 | 920 | ||

| GZG130-160 | 130×160×30 | 480 | 670 | 350 | 4 | 3.80 | 2×1.50 | 1040 | ||

| GZG150-180 | 150×180×30 | 720 | 1000 | 500 | 4 | 5.57 | 2×2.20 | 1420 | ||

| GZG180-200 | 180×200×37.5 | 900 | 1200 | 500 | 4 | 960 | 9..37 | 2×3.70 | 2350 | |

| GZG200-200 | 200×200×40 | 1000 | 1400 | 500 | 4 | 9.37 | 2×3.70 | 2700 | ||

| GZG200-240 | 320×240×50 | 1600 | 2000 | 500 | 4 | 13.60 | 2×5.50 | 3500 | ||

How to use

- The vibrating feeder should have a horizontal clearance of 20mm after installation, and the suspension device should be connected flexibly.

- Before the empty test, all bolts should be tightened once, especially the anchor bolts of the vibration motor. It should be tightened once for 3-5 hours.

- When the test is started, the two vibration motors must rotate in the opposite direction, and the stability of the current and noise should be stopped in time.

- The motor bearing is filled with grease once every 2 months, and the lubricating oil should be filled once a month during the high-temperature season.

Maintain

- Check whether the condition of the machine and the transmission part is normal before it can start;

- Must be started without load;

- After starting, if the abnormal situation is found, it should stop immediately, to be identified and ruled out the exception before starting again.

- Only when the machine has stable vibration can it run with the material.

- The feeding should meet the requirements of the load test;

- Shutdowns should be carried out in the process order, and no material shutdowns are prohibited.