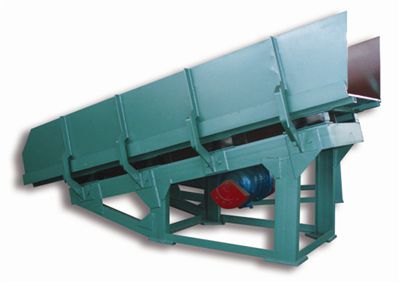

FZC Type Vibratory Feeder

FZC Type Vibratory Feeder

FZC type vibratory feeder is suitable for chutes, stopes, chutes,, and mine (material) bins where the ambient temperature does not exceed ±40°C and the relative humidity of the air does not exceed 90%. The ideal equipment for loading, is all kinds of mine cars, automobiles, train belts, cableway mine buckets, mine hoisting, and loading, and some jaw crushers can choose FZC series vibratory machines to mine.

Single-body vibratory feeder

If the ore is broken evenly, with small lumps and good fluidity, the swing or wave type can be selected. It is easy to arch and block and needs secondary crushing, so it is suitable for elliptical vibration types and directional vibration types.

Two-mass vibratory feeder

The principle of two-mass near-resonance inertial vibration is adopted. Single or double rows of shear rubber springs are arranged up and down, and the lower pressure plate is connected to the balance body by bolts, and then the left and right side plates are connected to the tank body. Compact structure, balanced pressure, and stable start, not affected by tank material load and jamming, ore feeding particle size (0-850mm), large feeding capacity (8-1800t/h), stepless frequency converter can be configured to realize frequency conversion feeding, Ingredients, remote computer operation control.

6 Characteristics of FZC Type Vibratory Feeder

- Small size, lightweight, simple and compact structure, less investment;

- Easy installation, less maintenance, low operating cost, less power consumption, and remarkable energy saving;

- Due to vibration, the fluidity of ore and rock materials increases, reducing channel blockage, so the ore drawing capacity is large and the efficiency is high;

- The vibrated ore flow is continuous, uniform, and easy to control, the size of the ore flow can be adjusted according to the needs, and the operation is safe and reliable;

- Work in the super-resonant state, the amplitude is stable, it can be started frequently (starting times ≤ 200 times/hour), the load on the vibrating table plate is allowed to fluctuate greatly, and it has strong adaptability to various ore rocks, especially viscous ore materials. , and can work in a dusty or watery environment;

- This series of vibrating ore drawers can be used for loose ore materials whose weight is not more than 2.4 tons/m, and whose lump size is not more than 1000mm or less than 1000mm to fine ore.

Read More: Feeder Wikipedia

Technical Data Sheet

| Mold | Type | Table length L(m) | Table width B(m) | Maximum ore lumpiness (mm) | Production Capacity Q (t/h) | Table inclination A (degrees) | Rated vibration frequency N times/min | Amplitude A | Maximum exciting force P kN | Rated power N kilowatts | Machine weight G kg | Embedded parameters | ||

| mm | Buried depth m | Eyebrow Height m | Brow line angle (degrees) | |||||||||||

| 1 | FZC-1.6/1-1.5 | 1.6 | 1 | 350 | 300-360 | 12 | 1420 | 0.8 | 10 | 1.5 | 440 | 0.6 | 0.6 | 40 |

| 2 | -3.5 | 1.8 | 0.9 | 350-400 | 12 | 1420 | 0.9 | 10 | 1.5 | 430 | 0.6 | 0.7 | 40 | |

| 3 | -4 | 2 | 0.8 | 310-370 | 14 | 1420 | 0.9 | 10 | 1.5 | 490 | 0.6 | 0.7 | 38 | |

| 4 | -4.7857143 | 2.3 | 0.7 | 290-330 | 16 | 1420 | 0.8 | 10 | 1.5 | 575 | 0.7 | 0.7 | 38 | |

| 5 | FZC-2/1-3 | 2 | 1 | 850-1000 | 14 | 960 | 3 | 20 | 3 | 690 | 0.7 | 0.7 | 40 | |

| 6 | -5.5555556 | 2.3 | 0.9 | 770-910 | 14 | 960 | 3 | 20 | 3 | 870 | 0.8 | 0.8 | 40 | |

| 7 | FZC-2.3/1.2-3 | 2.3 | 1.2 | 630-760 | 14 | 960 | 1.8 | 20 | 3 | 960 | 0.8 | 0.8 | 40 | |

| 8 | -5.8 | 2.8 | 1 | 580-690 | 18 | 960 | 1.7 | 20 | 3 | 1000 | 0.9 | 0.9 | 41 | |

| 9 | -5.9166667 | 2.3 | 1.2 | 500 | 630-730 | 14 | 1420 | 0.9 | 30 | 4 | 1010 | 0.9 | 0.8 | 41 |

| 10 | FZC-2.5/1.2-3 | 2.5 | 1.2 | 590-720 | 16 | 960 | 1.7 | 20 | 3 | 980 | 0.8 | 0.8 | 39 | |

| 11 | -6.1 | 3.1 | 1 | 560-670 | 18 | 960 | 1.7 | 20 | 3 | 1060 | 0.8 | 0.9 | 38 | |

| 12 | -6.0833333 | 2.5 | 1.2 | 660-770 | 16 | 1420 | 0.9 | 30 | 4 | 1030 | 0.8 | 0.9 | 41 | |

| 13 | -7.1 | 3.1 | 1 | 350 | 760-870 | 18 | 1420 | 1 | 30 | 4 | 1110 | 0.9 | 0.9 | 38 |

| 14 | -7.8888889 | 3.5 | 0.9 | 730-830 | 18 | 1420 | 1 | 30 | 4 | 1130 | 0.9 | 1 | 37 | |

| 15 | FZC-2.5/1.4-5.5 | 2.5 | 1.4 | 500 | 990-1180 | 14 | 960 | 2 | 40 | 5.5 | 1360 | 0.9 | 0.9 | 41 |

| 16 | -9 | 3.5 | 1 | 980-1150 | 18 | 960 | 2 | 40 | 5 | 1525 | 1.1 | 1.1 | 40 | |

| 17 | FZC-2.8/1.4-5.5 | 2.8 | 1.4 | 900-1080 | 14 | 960 | 1.8 | 40 | 5.5 | 1460 | 1 | 1 | 41 | |

| 18 | -8.0833333 | 3.1 | 1.2 | 910-1090 | 14 | 960 | 1.8 | 40 | 5.5 | 1515 | 1.1 | 1.1 | 40 | |

| 19 | FZC-3.1/1.4-5.5 | 3.1 | 1.4 | 500 | 920-1120 | 14 | 960 | 1.7 | 40 | 5.5 | 1600 | 1 | 1.1 | 39 |

| 20 | -8.4166667 | 3.5 | 1.2 | 870-1050 | 14 | 960 | 1.8 | 40 | 5.5 | 1570 | 1 | 1.1 | 36 | |

| 21 | -10 | 4.5 | 1 | 830-980 | 18 | 960 | 1.8 | 40 | 5.5 | 2040 | 1 | 1.1 | 34 | |

| 22 | -9.7142857 | 3.1 | 1.4 | 1260-1500 | 14 | 960 | 2 | 40 | 5.5 | 1875 | 1.1 | 1.1 | 40 | |

| 23 | -10.416667 | 3.5 | 1.2 | 1220-1440 | 14 | 960 | 2.1 | 50 | 7.5 | 1810 | 1.2 | 1.2 | 39 | |

| 24 | -12 | 4.5 | 1 | 1290-1510 | 15 | 960 | 2 | 50 | 7.5 | 2225 | 1.2 | 1.4 | 39 | |

| 25 | FZC-3.5/1.4-7.5 | 3.5 | 1.4 | 650 | 1160-1380 | 14 | 960 | 1.8 | 50 | 7.5 | 3000 | 1 | 1.2 | 37 |

| 26 | -10.833333 | 4 | 1.2 | 870-1040 | 18 | 960 | 1.6 | 50 | 7.5 | 1935 | 1.2 | 1.2 | 39 | |

| 27 | FZC-5/1-7.5 | 5 | 1 | 500 | 840-1010 | 18 | 960 | 1.6 | 50 | 7.5 | 2355 | 1.2 | 1.4 | 37 |

| 28 | FZC-4//1.6-10 | 4 | 1.6 | 1570-1870 | 16 | 960 | 1.8 | 75 | 10 | 2355 | 1.2 | 1.4 | 40 | |

| 29 | FZC-5/1.4-10 | 5 | 1.4 | 1300-1550 | 18 | 960 | 1.7 | 75 | 10 | 2800 | 1.4 | 1.4 | 38 | |

| 30 | FZC-3.1/1×2-4×2 | 3.1 | 1.0×2 | 1520-1740 | 18 | 1420 | 1.2 | 30×2 | 4.0×2 | 2220 | 0.9 | 0.9 | 38 | |

| 31 | FZC-3.5/1×2-5.5×2 | 3.5 | 1.0×2 | 1960-2300 | 18 | 960 | 2 | 40×2 | 5.5×2 | 3050 | 1.1 | 1.1 | 40 | |

| 32 | -3.5/1.2×2-5.5×2 | 3.1 | 1.2×2 | 1820-2180 | 14 | 960 | 1.8 | 40×2 | 5.5×2 | 3030 | 1.1 | 1.1 | 40 | |

| 33 | FZC-3.5/1.2×2-75.5×2 | 3.5 | 1.2×2 | 1740-2100 | 14 | 960 | 1.8 | 40×2 | 5.5×2 | 3310 | 1 | 1.1 | 36 | |

| 34 | -3.5/1.4-3×2-7.5×2 | 3.5 | 1.4×2 | 2320-2760 | 14 | 960 | 1.8 | 50×2 | 7.5×2 | 3970 | 1 | 1.2 | 37 | |

| 35 | -4/1.2×2-7.5×2 | 4 | 1.4×2 | 1740-2080 | 18 | 960 | 1.6 | 50×2 | 7.5×2 | 3870 | 1 | 1.2 | 39 | |

Read More: Guide to the Best Vibratory Feeder & Grizzly Feeder in 2023

9 requirements for the work of FZC vibratory feeder

- Before installing the seat-type vibratory feeder, first, compare the site foundation with the installation drawing of the vibratory feeder. After inspection, pre-embed the steel plate, the thickness of the steel plate is 20mm, and the flatness is not more than 1.5%.

- After the vibratory feeder is installed, the relative position is adjusted, and then the spring base and the pre-embedded steel plate is spot welded firmly.

- It is required that the direction of rotation of the two vibration motors must be opposite.

- Run for 1 hour after installation, check whether the body is running smoothly, the yaw is not greater than 0.5mm, and the vibration motor bolts are fastened.

- If the processing capacity is insufficient during use, the excitation force of the vibration motor can be adjusted to achieve the best effect if possible.

- Adjustment of excitation force: a. Remove the protective cover b. Loosen the two inner eccentric blocks c. Adjust the two outer strange blocks with the same phase and angle d. Tighten the adjusting bolts and install the protective cover e. The vibration motor bearing The temperature rise is not more than 80OC (resistance method).

- During the working process of the vibratory feeder, you should pay attention to whether the body movement is stable. If you find that the operation is not normal or there is an abnormal sound, you should stop it immediately for an inspection.

- The bearings of the vibration motor are lubricated with 3# lithium base grease once a week, and the bearings should be checked and cleaned once a year to check the degree of wear of the bearings, and replace and repair in time if necessary.

- Always check whether the fastening bolts at the connecting parts are loose, and eliminate hidden dangers in time.