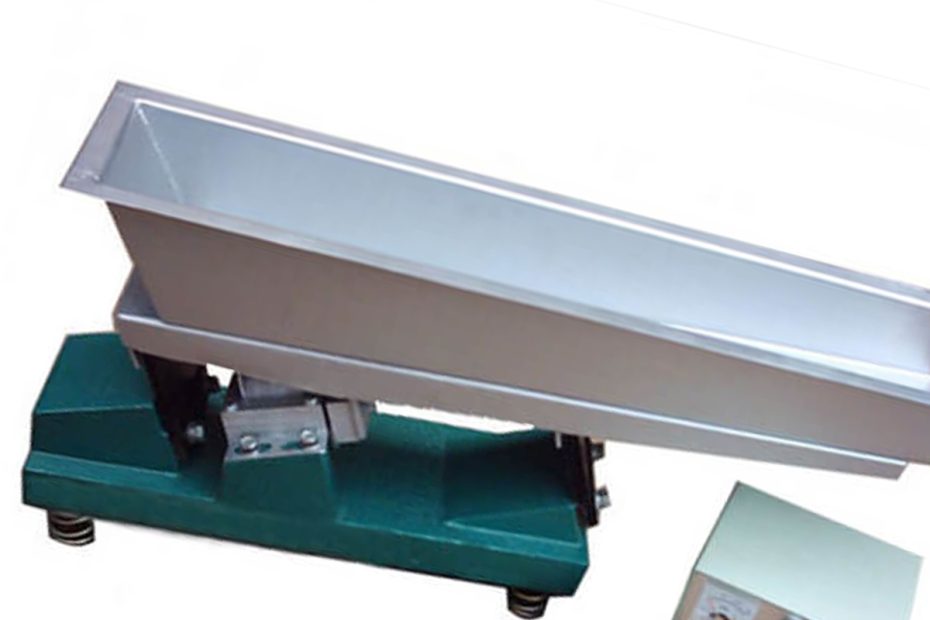

The exciter of the micro electromagnetic vibrating feeder is composed of a spiral tube type electromagnet composed of an iron core, an armature and an electromagnetic coil. The iron core and the armature are made of soft iron (pure iron). The iron core is consolidated with the base through the cover plate. The armature is directly fixed on the force transmission plate, and the air gap is adjusted by the thread of the iron core and the fastening nut.

The leaf spring is made of 0.5~2 mm thin spring steel plate, and the trough is made of ordinary steel plate, stainless steel plate or lead plate. The trough amplitude of this exciter can reach 1.5~2 mm, and it uses single-phase half-wave rectification power supply with a vibration frequency of 3000 times/min.

Characteristics of the exciter of the micro electromagnetic vibrating feeder

- When a spiral tube electromagnet is used, the magnetic circuit can be simple;

- When the iron core and the armature are made of pure iron, the structure is simple, and it is easy to manufacture and install.

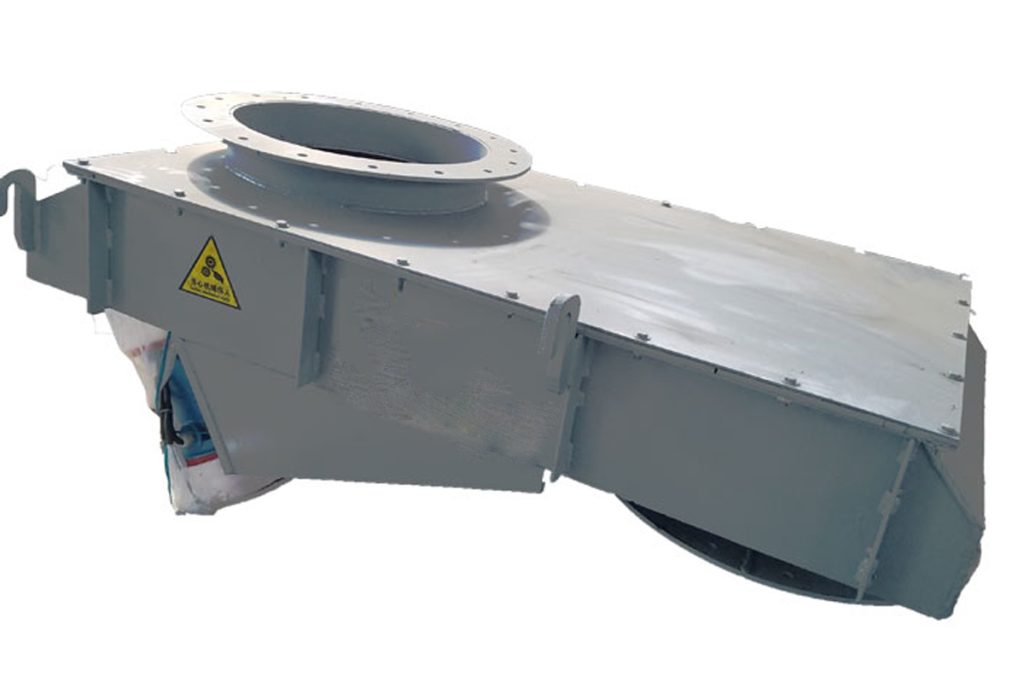

- According to actual production needs, the electromagnetic exciter can also be made into an inflatable explosion-proof type and a shell explosion-proof type.

- The exciter of the electromagnetic vibrating feeder is installed at the lower rear of the trough body with a basket screw suspension.

Installation precautions for micro electromagnetic vibrating feeder

- The trough body is installed at a downward inclination of 10°, but for sticky materials or materials with high moisture content, the downward inclination angle can be increased to 15°, and the material should be prevented from flowing by itself.

- The electromagnetic vibrating feeder is very sensitive to load, which affects the output of the equipment and causes equipment damage. When installing, try to reduce the bin pressure acting on the feeder, such as adding an inclined plate at the discharge port to reduce the direct vertical effect of the material on the trough body.

- After the equipment is installed on site, open the inspection cover of the shell, check and adjust the assembly air gap between the iron cores to the standard value of 2±0.1mm, and keep the working surface parallel (horizontal degree less than 0.15mm); confirm that there is no foreign matter in the assembly air gap; all fastening bolts must use anti-loosening washers; the equipment body should be sealed according to the protection level specified in the design to prevent dust and moisture from entering and causing failures.

Conclusion

The electromagnetic vibrating feeder has a simple structure, stable operation, low power loss, and convenient operation. It can evenly adjust the feed rate. The equipment is widely used in mining, metallurgy, coal, electricity, chemical industry, food, glass, refractory materials and other industries.