When it comes to moving bulk materials from one place to another, vibrating conveyors are often used as an efficient and reliable option. Vibrating conveyors are known for their ability to move materials in a gentle, fluid-like manner, helping to reduce degradation and breakage while minimizing noise and energy consumption. In this article, we will explore the different types of vibrating conveyors available and discuss their advantages.

Four Types of Vibrating Conveyors

Horizontal Vibrating Conveyors:

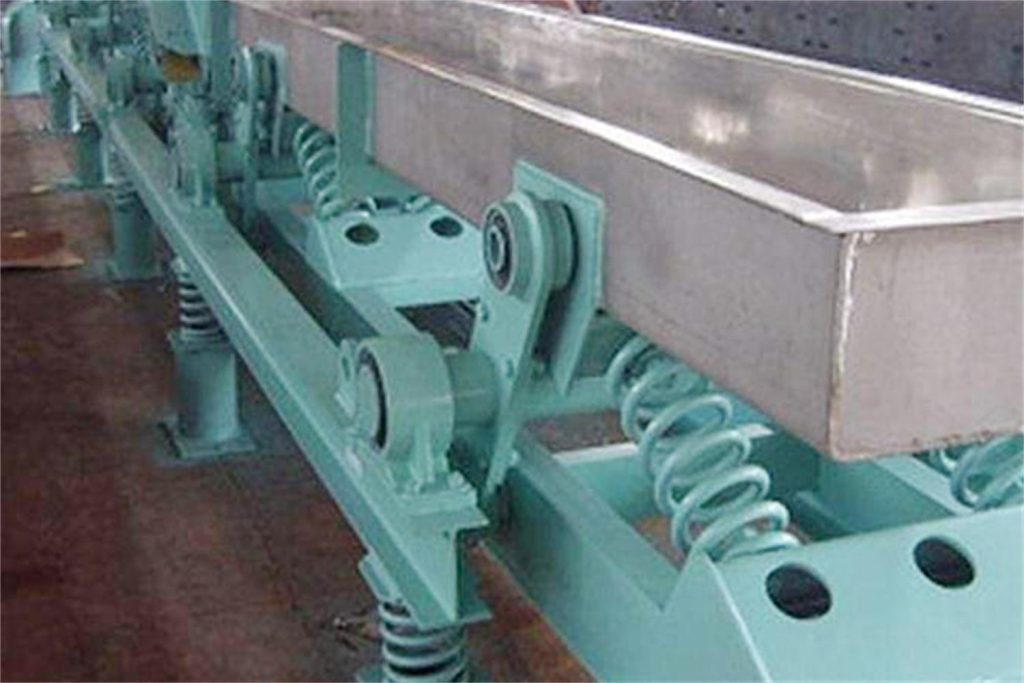

A horizontal vibrating conveyor consists of a bed or trough that rests on top of a vibrating drive mechanism, which imparts a vibratory motion to the bed. The material being conveyed is fed onto the bed, and as the bed vibrates, the material moves forward in a horizontal direction. Horizontal vibrating conveyors are often used for long distances and can handle heavy loads.

Advantages

- Great for conveying heavy loads

- Reduced material degradation

- Minimal noise generation

- Low energy consumption

Vertical Vibrating Conveyors

In a vertical vibrating conveyor, material is conveyed upwards in a vertical direction. These types of conveyors are often used to transfer materials from one level to another or to feed material into a processing system. Vertical vibrating conveyors are commonly used in industries such as agriculture, food processing, and recycling.

Advantages

- Cost-effective method of moving material vertically

- Reliable and durable

- Gentle movement of materials for reduced degradation

Vibrating Spiral Conveyors

A vibrating spiral conveyor uses a helical screw to move material along a trough while vibrating in a circular motion. This type of conveyor is ideal for conveying fragile or granular materials that require gentle treatment, such as powders and grains.

Advantages

- Reduced breakage and degradation of fragile materials

- Uniform material flow

- Can handle large volumes of material

- Energy-efficient

Vibrating Tube Conveyors

Vibrating tube conveyors use a tube-shaped trough that is mounted on helical springs and driven by a vibratory motor. Material is fed into the tube, and as the tube vibrates, the material is transported along the length of the tube. Vibrating tube conveyors are often used for conveying abrasive or corrosive materials.

Advantages

- Minimal material degradation

- Energy-efficient

- Can handle abrasive and corrosive materials

- Reduced noise levels

Advantages of Using a Vibrating Conveyor

Gentle Material Handling

One of the major benefits of using a vibrating conveyor is the gentle handling of the material being transported. The vibration of the conveyor bed ensures that the material is moved in a fluid-like motion, minimizing the risk of breakage or degradation. This is particularly important when conveying fragile materials or products that need to maintain their integrity, such as food or pharmaceuticals.

Reduced Noise Levels

Another significant advantage of vibrating conveyors is their low noise generation. Because the material is conveyed through vibration rather than physical contact, there is reduced noise during transportation. This makes vibrating conveyors a more pleasant and safer working environment for operators and reduces the impact of noise pollution on the surrounding environment.

Energy Efficiency

Vibrating conveyors are also known for their energy efficiency. The vibratory motion of the conveyor bed requires less energy than traditional conveyor systems, reducing energy consumption and operating costs.

Minimal Maintenance

Vibrating conveyors require minimal maintenance compared to other conveyor systems. The lack of moving parts reduces the need for repairs, and the simple design makes troubleshooting and maintenance tasks easier.

Summary

Vibrating conveyors are a reliable and efficient way to move a variety of materials from one place to another. With their gentle material handling, reduced noise levels, energy efficiency, and minimal maintenance requirements, vibrating conveyors are an ideal choice for many industries. Whether you need to transport heavy loads horizontally or move fragile materials vertically, there is a vibrating conveyor to suit your needs.

If you’re interested in learning more about vibrating conveyors, here are some recommended resources to help you get started:

- General Kinematics: “Vibrating Conveyor Systems for Bulk Material Processing” – https://www.generalkinematics.com/blog/vibrating-conveyor-systems-for-bulk-material-processing/

- Meyer Industrial: “Vibratory Conveyors vs Belt Conveyors: The Choice for Food Processing” – https://www.meyer-industries.com/blog/vibratory-conveyors-vs-belt-conveyors-the-choice-for-food-processing/

- Smalley Manufacturing: “Vibratory Conveyor Systems & Equipment” – https://www.smalleymanufacturing.com/products/vibratory-conveyor/

- Action Equipment Company: “Vibratory Conveyors: Features and Benefits” – https://www.actionconveyors.com/vibratory-conveyors.php

In conclusion, vibrating conveyors are a versatile and efficient method of moving bulk materials from one place to another. There are several different types of vibrating conveyors available, each with their own unique advantages and applications. Whether you need a conveyor to transport heavy loads horizontally or move fragile materials vertically, a vibrating conveyor is an excellent choice. With their gentle material handling, energy efficiency, and low maintenance requirements, vibrating conveyors are an ideal solution for many different industries.