Vibrating Screen Manufacturers

Heavy-Duty Linear Vibrating Screens

ZSG high-efficiency heavy-duty vibrating screen is a new type of high-efficiency general-purpose screening equipment

ZSG Heavy-Duty Linear Vibrating Screens

ZSG series high-efficiency heavy-duty vibrating screen is a new type of screening equipment. The motion track of the screen box is approximately a straight line. It has a simple structure, large screening capacity, low energy consumption, and easy maintenance.

ZSG series high-efficiency heavy-duty vibrating screens are widely used in mining, coal, electric power, metallurgy, building materials, refractory, and other industries to classify large and fast materials and medium and small granular materials, especially in the metallurgical industry. Vibrating screens are commonly used in tanks, coking plants, and mineral processing plants.

Two Types and Applications of ZSG Heavy-Duty Linear Vibrating Screens

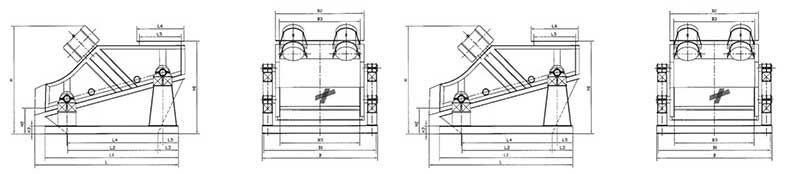

- Open-type high-efficiency heavy-duty vibrating screen: pedestal type, without dust cover structure, used for screening operations of large screening capacity and non-dust-polluted granular materials.

- Enclosed high-efficiency heavy-duty vibrating screen: seat type, fully enclosed structure, used for screening operations of large-capacity, dust-contaminated granular materials.

Remarks: There are various forms of equipment installation, such as support type, hanging type, and a combination of the two. Please consider carefully when selecting the type.

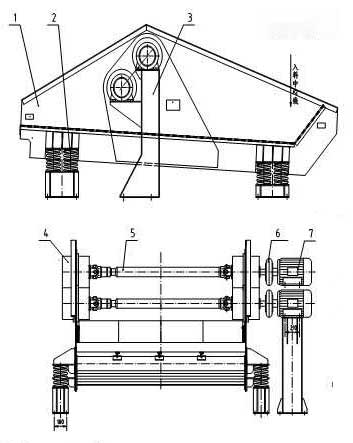

Structure of ZSG Heavy-Duty Linear Vibrating Screens

ZSG series high-efficiency heavy-duty vibrating screen consists of a vibration excitation device, screen box, dust cover, drop hopper, vibration damping device, base, and other parts.

The power device has two forms: direct drive of YZO series vibration motor and indirect drive of the ordinary motor through coupling to drive vibrator, which can meet the needs of different environments;

The screen surface has various forms such as metal braided mesh, rod, casting, welding, punching, etc. The screen surface can have a single-layer or multi-layer structure, which can meet the requirements of different screening operations.

Working principle of ZSG Heavy-Duty Linear Vibrating Screens

When the ZSG series high-efficiency heavy-duty vibrating screen is working, the exciting force generated by the exciter is transmitted to the screen surface in the screen box through the screen box. The exciting force generated by the vibrator is a longitudinal force, forcing the screen box to drive the screen surface. For longitudinal displacement, under certain conditions, the material on the screen surface is thrown forward due to the excited vibration force, and when falling, the material smaller than the screen hole will pass through the screen and fall to the lower layer. The movement track is a parabolic movement. Due to such repeated material movement, the material screening operation is completed.

Read More: Guide to the Best Vibrating Screen in 2023

Five features of ZSG Heavy-Duty Linear Vibrating Screens

The ZSG series high-efficiency heavy-duty vibrating screen is installed with an inclined screen surface and has the following characteristics:

- Small size, large screening capacity;

- High-efficiency heavy-duty vibrating screen is light in weight, easy to install and process layout;

- Less energy consumption can save energy;

- Simple structure and beautiful appearance;

- The screens are assembled from small pieces and are extremely easy to replace.

Technical Parameter of ZSG Heavy-Duty Linear Vibrating Screens

| Model | Screening capacity | Motor | Voltage | Power | Vibration frequency | Double amplitude | Sieve |

Weight (kg) |

dynamic load | |||

| Mesh Size/mm | t/h | Model | V | kW | Number of times/min | mm |

Effective sieving surface m2 |

Mesh size mm |

Single layer | Double layer | kg | |

| ZSG-10×20 | ≤250 | 10-200 | YZO-30-6 | 380 | 2.2×2 | 960 | 8-12 | 2 | 3-50 | 2300 | 2500 | 130 |

| ZSG-10×30 | ≤350 | 15-250 | YZO-30-6 | 380 | 2.2×2 | 960 | 8-12 | 3 | 3-150 | 3300 | 3600 | 185 |

| ZSG-15×30 | ≤400 | 20-350 | YZO-50-6 | 380 | 3.7×2 | 960 | 8-12 | 4.5 | 3-200 | 5100 | 5500 | 281 |

| ZSG-15×40 | ≤400 | 25-400 | YZO-50-6 | 380 | 3.7×2 | 960 | 6-10 | 6 | 3-200 | 6800 | 7300 | 372 |

| ZSG-15×50 | ≤400 | 30-500 | YZO-80-6 | 380 | 5.5×2 | 960 | 6-10 | 7.5 | 3-200 | 8450 | 9100 | 465 |

| ZSG-20×50 | ≤400 | 50-500 | YZO-80-6 | 380 | 5.5×2 | 960 | 6-10 | 10 | 3-200 | 11100 | 12000 | 613 |

| ZSG-20×50 | ≤400 | 60-600 | YZ0-100-8 | 380 | 6.3×2 | 720 | 10-15 | 12 | 3-200 | 13800 | 14900 | 760 |

| ZSG-20×70 | ≤400 | 65-600 | YZ0-100-8 | 380 | 6.3×2 | 720 | 8-12 | 14 | 3-200 | 17500 | 19800 | 1011 |

| ZSG-20×80 | ≤400 | 65-600 | YZ0-100-8 | 380 | 6.3×2 | 720 | 6-12 | 16 | 3-200 | 21820 | 23400 | 1194 |

Read More: Vibrating Screen Wikipedia