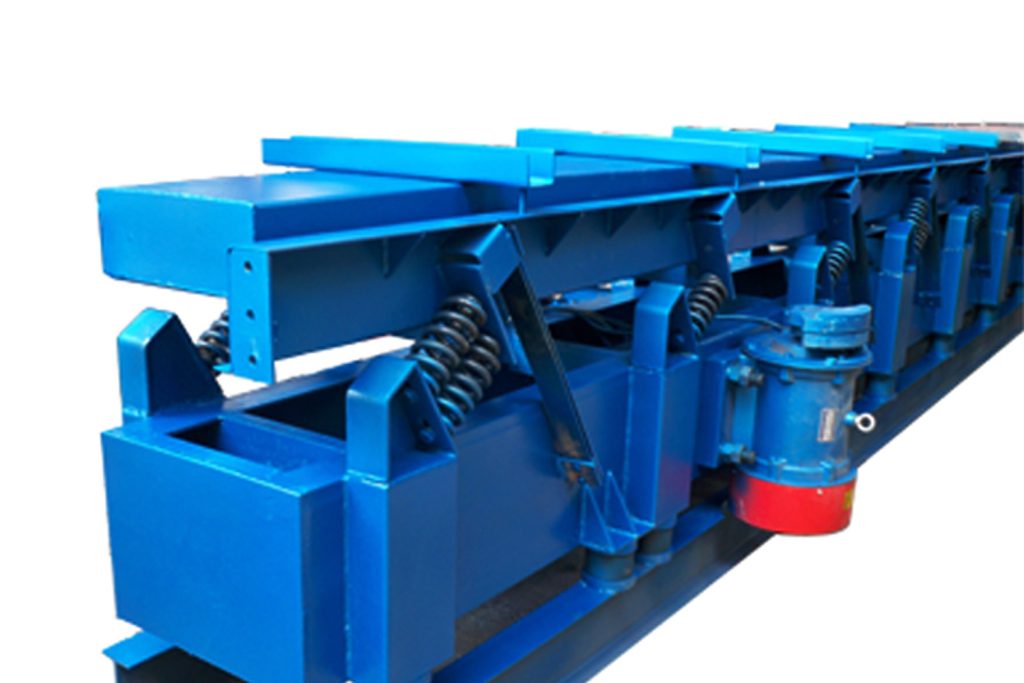

Inertial vibrating conveyoris a kind of equipment that uses inertial force to realize material transportation. It is mainly composed of vibration motor, reduction box, inertial eccentric body and sieve plate. When the equipment is started, the material is pushed onto the sieve plate by the inertial eccentric force to achieve the purpose of material classification and grading.

However, in the process of using the inertial vibrating conveyor, some failures will also be encountered. This article will introduce the reasons for the failure of the inertial vibrating conveyor and the corresponding treatment methods.

Vibration motor failure

cause of issue:

- Poor electrical contact, causing the device to fail to start or to run erratically.

- Excessive wear or damage to the motor bearings, causing the equipment to vibrate excessively, make excessive noise, or fail to function properly.

- The motor windings heat up, causing the device to be overloaded or short-circuited.

Troubleshooting:

- Check the power supply and electrical wiring to ensure good electrical contact;

- Check the wear and damage of bearings and replace them in time;

- Check the heating of the motor windings, clean the surrounding environment of the motor, and reduce overloading.

Gearbox failure

cause of issue:

- The oil temperature of the gearbox is too high, resulting in oil leakage or excessive bearing temperature.

- Improper assembly of gears results in decreased transmission accuracy or overload conditions.

- Gearbox bearings are excessively worn or damaged, resulting in excessive vibration, excessive noise, or malfunction of the equipment.

Troubleshooting:

- Pay attention to replace the lubricating oil of the gearbox in time to maintain an appropriate temperature;

- Check the gear assembly to ensure transmission accuracy and overload conditions;

- Check the gear box bearings for wear and replace them in time.

Fault of inertial eccentric body

cause of issue:

- The connection between the inertial eccentric body and the main shaft is loose, which hinders the rotation of the inertial eccentric body itself or causes unstable vibration amplitude.

- The surface of the inertial eccentric is heavily soiled, which reduces the intensity and effectiveness of the vibration action.

Troubleshooting:

- Check the position of the inertial vibration bearing, tighten the connection part, prevent the inertial eccentric body from shifting, and cause the vibration amplitude to be unstable;

- Clean the equipment regularly to maintain the cleanliness of the surface of the inertial eccentric body.

sieve plate failure

cause of issue:

The sieve plate is too worn or improperly laid, resulting in unstable particle size and material delivery.

The structure of the sieve plate is damaged, resulting in material leakage or loss of classification function.

Troubleshooting:

When installing and using, the sieve plate should be installed correctly according to the requirements;

Regularly check the use of the sieve plate, and replace the hand setting in time to make it suitable for the size;

When the sieve plate is damaged, repair or replace it in time.

In summary

Due to the complexity of the work and the reasons of the equipment itself, the inertial vibrating conveyor system will inevitably fail. Only by strengthening maintenance and maintenance, and timely finding and handling of faults, can the service life and working efficiency of the equipment be better guaranteed.