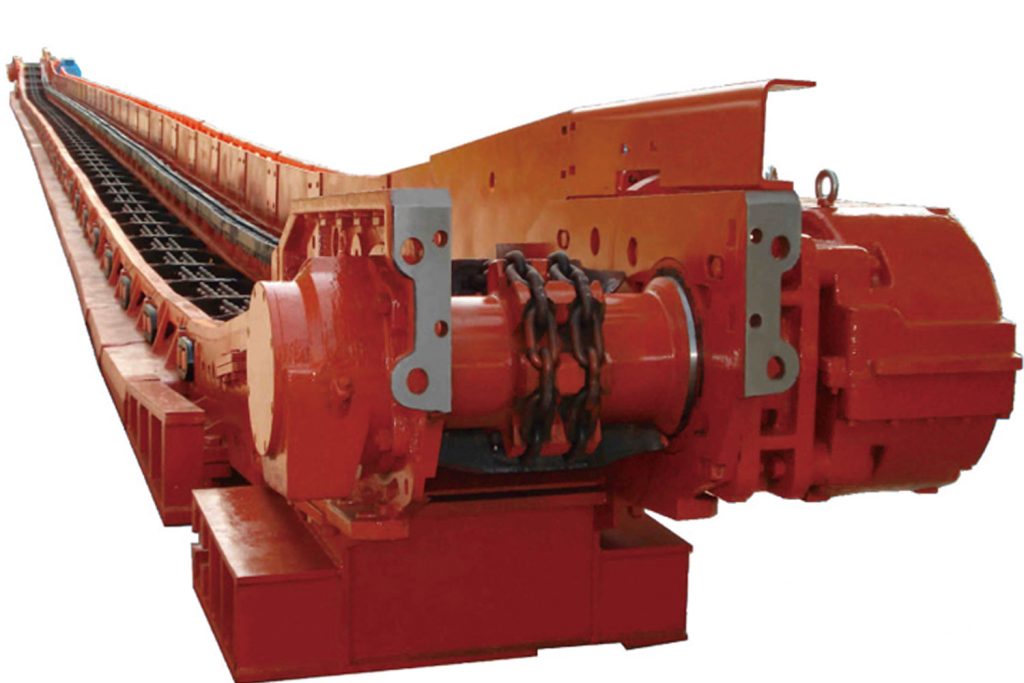

Buried scraper conveyor is a common material conveyor system, which is a continuous transportation equipment that uses the moving scraper chain to continuously transport bulk materials within a closed rectangular section or circular tube-shaped shell. It is called “buried scraper conveyor” because the scraper chain is buried in the material and moves forward with the material during operation.

The buried scraper conveyor is a conveying mechanism with flexible traction components. It firmly fixes the scraper on the chain through a set of chains, and then drives the scraper to move along the conveying path by driving the chain with an electric motor. The scraper chain uniformly moves and runs under the transmission of the motor and reducer. It smoothly pulls the bulk material forward through the traction of the scraper chain to achieve material conveying and stacking.

The buried scraper conveyor can transport powdered, granular, and small-sized materials in a horizontal, inclined, or vertical direction. Its overall structure is reasonable, and it can feed and discharge from multiple points.

7 advantages of buried scraper conveyor

- High conveying efficiency: The buried scraper conveyor adopts a scraper chain traction method, which can move the material forward by continuously rotating the chain, achieving high efficiency conveying. Moreover, there is basically no relative movement between the material and the scraper chain during the conveying process, reducing wear on the material.

- High safety: The mechanism of the buried scraper conveyor adopts a closed design, which can effectively control material scattering and pollution, avoiding harm to the environment and human beings. At the same time, the equipment can also be equipped with various safety protection devices, such as limit switches and power-off protection, to ensure the safety of equipment and personnel.

- Strong adaptability: Buried scraper conveyors can select different materials, specifications, and configurations based on different working environments and material characteristics to meet different conveying requirements and needs.

- Strong wear resistance: The chain of the buried scraper conveyor is made of high-strength material, which has characteristics such as wear resistance, corrosion resistance, and high-temperature resistance, extending the service life of the equipment.

- Good sealing performance: The material is transported in a closed machine slot, without scattering, leakage, dustproof, waterproof, and explosion-proof, improving working conditions and preventing environmental pollution.

- Energy-saving and environmentally friendly: The buried scraper conveyor uses an electric motor for power, which compared with other traditional conveying equipment, has lower energy consumption, and can effectively control material dust and pollution, meeting environmental protection requirements.

- Small floor space: The volume of the buried scraper conveyor is small and it can be installed and used in relatively narrow working areas. It is easy to operate, maintain, and operate safely and reliably.

Five major disadvantages of buried scraper conveyor

- High noise: During operation, the buried scraper conveyor will produce some noise, affecting the working environment and personnel’s comfort.

- Difficult maintenance: The buried scraper conveyor is composed of many parts, such as sprockets, scraper chains, and pulleys. If any of these parts have problems, it will affect the normal operation of the entire equipment, and the maintenance difficulty is relatively high, requiring professional skills.

- Limited transmission distance: The material conveying distance and lifting height of the buried scraper conveyor are limited. Currently, within a distance of 2.5 km, the installation of a tunnel is required. But for slightly longer distances, it can be shortened through underground support panels. Compared with pipe belts and conveyor belts, the conveying distance of buried scraper conveyors is relatively limited.

- Large wear of scraper chain and machine slot: The wear parts are mainly the chain joint, the bottom plate of the machine slot, and the guide rail, especially when conveying dust-like materials with higher abrasiveness.

- Large power consumption: It is not suitable for conveying materials that are highly viscous, suspended, large in particle size, or have a great tendency to wear.

summary

The buried scraper conveyor has the advantages of wide use, multiple materials transportation, and flexible process layout. Although it also has some disadvantages, they can be solved through reasonable selection and accessories.

At the same time, its excellent performance, high working efficiency, and good adaptability have been widely used in many industries.