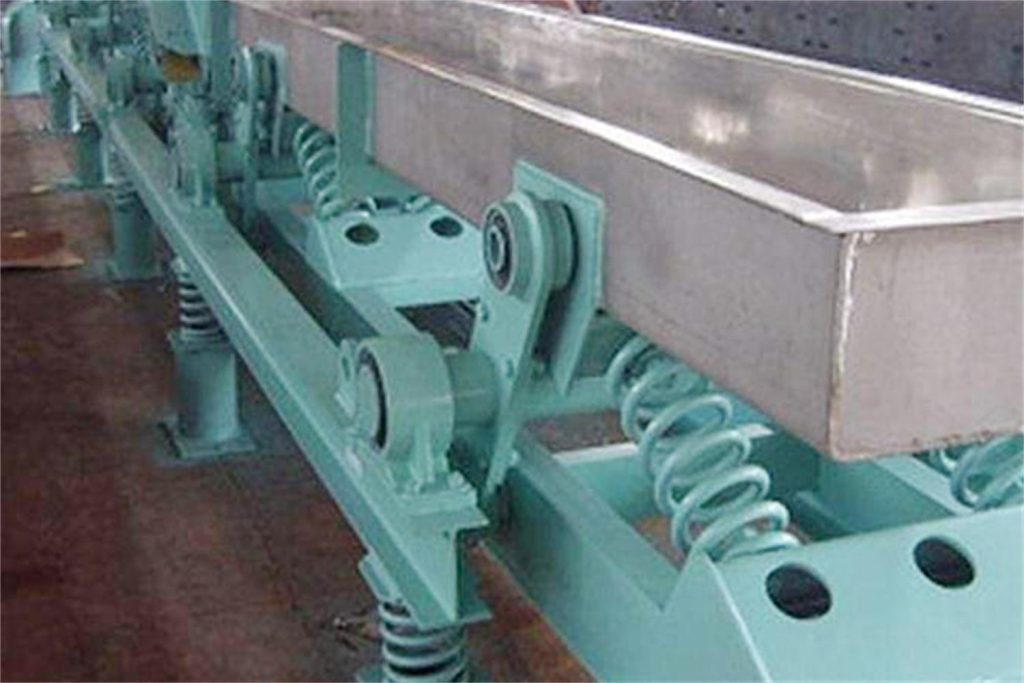

A vibrating conveyor is a material conveying device that uses vibration force to convey materials from one point to another. It is very common in various fields, including mining, chemical industry, food, building materials, etc.

During the use of vibrating conveyors, various failures are often encountered, which will not only affect the continuity of production, but also affect the service life of the equipment.

Factors that cause machine body vibration failure

- The vibrating conveyor is not installed smoothly or fixed firmly, resulting in uneven force;

- The foundation of the equipment on which the vibrating conveyor is located is not stable, resulting in unstable movement;

- The components of the vibrating conveyor are damaged or worn, resulting in the loss of balance of bearings and connectors;

- The vibrator is loose or damaged, resulting in abnormal noise;

- Disturbed by external factors such as wind, earthquake, etc.;

Solutions to body vibration problems

First check whether there is looseness caused by loose installation, disassemble the loose parts and fix or tighten them again, and readjust the balance of the body according to the instruction manual;

Secondly, check and replace the parts to ensure that the bearings and connectors are in normal use;

Finally, if the vibration of the body is caused by external environmental factors, the interference of the external environment on equipment manufacturing can be avoided or reduced by adding protective measures.

In summary

There is no need to panic when the vibrating conveyor encounters a failure. Instead, on the premise of correctly evaluating the problem, follow the relevant operating procedures, eliminate possible problems one by one, and have professional technicians repair and upgrade.

Only in this way can the normal operation of the vibrating conveyor be guaranteed and the continuity of production realized. During the long-term operation of the equipment, a maintenance and maintenance plan is formulated, and regular inspection and maintenance are carried out to ensure the normal operation of the equipment.