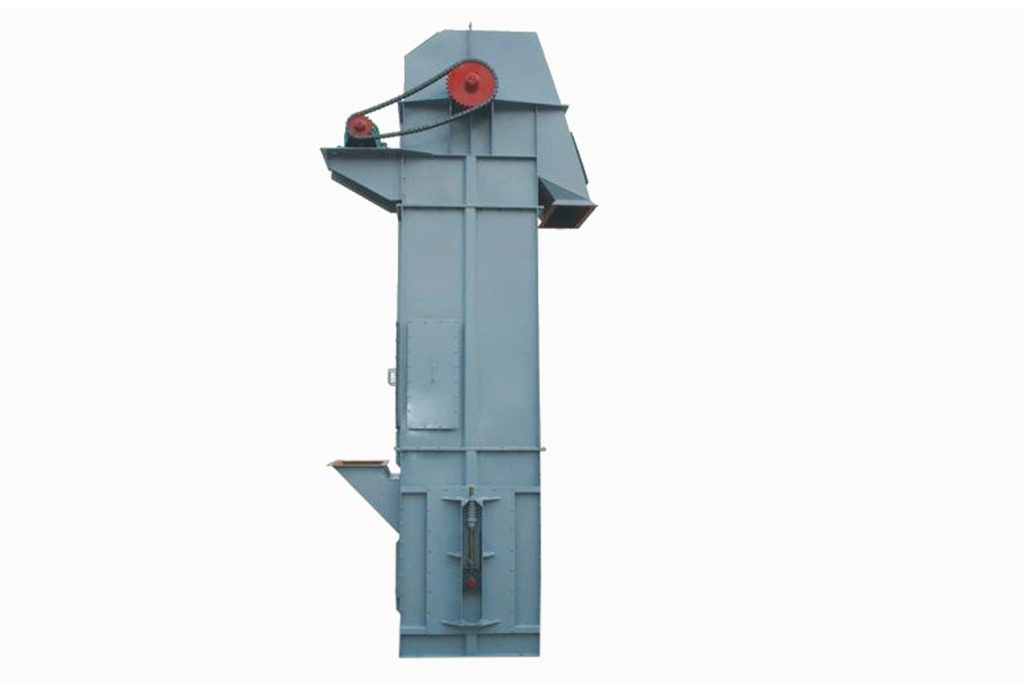

Bucket elevators serve as indispensable tools in industries such as agriculture, mining, and manufacturing, facilitating the vertical transport of bulk materials efficiently. Among the different types of bucket elevators, high-speed and low-speed variants stand out due to their distinct operational characteristics and applications.

Understanding High-Speed and Low-Speed Bucket Elevators

- High-Speed Bucket Elevators : High-speed bucket elevators are designed to operate at faster speeds, typically ranging from 125 to 300 feet per minute (fpm). They feature a higher rate of material throughput and are well-suited for applications requiring rapid vertical conveyance. These elevators are often utilized in industries where time-sensitive material handling is crucial, such as grain processing plants, cement production facilities, and fertilizer manufacturing.

- Low-Speed Bucket Elevators : In contrast, low-speed bucket elevators operate at slower speeds, typically ranging from 50 to 125 fpm. They offer a more gentle handling of materials, making them suitable for fragile or delicate products that require careful handling to prevent damage. Low-speed bucket elevators are commonly employed in industries such as food processing, pharmaceuticals, and chemicals, where product integrity is paramount.

Comparative Analysis : High-Speed vs. Low-Speed Bucket Elevators

To facilitate a better understanding of the differences between high-speed and low-speed bucket elevators, let’s examine their key attributes in a comparative table:

| Attributes | High-Speed Bucket Elevators | Low-Speed Bucket Elevators |

|---|---|---|

| Speed | 125 to 300 fpm | 50 to 125 fpm |

| Material Handling | Suitable for coarse materials and bulk commodities | Ideal for fragile or delicate products |

| Throughput Capacity | Higher throughput | Lower throughput |

| Power Consumption | Higher power consumption due to increased speed | Lower power consumption due to slower speed |

| Material Degradation | Increased risk of material degradation due to higher impact forces | Reduced risk of material degradation due to gentle handling |

Application Comparison Of High-Speed And Low-Speed Bucket Elevators

High-Speed Bucket Elevators:

- Grain Handling: High-speed bucket elevators are commonly used in grain handling facilities for efficient loading and unloading of bulk grains.

- Mining Operations: In mining applications, high-speed bucket elevators are employed for the vertical transport of ores, minerals, and aggregates.

- Cement Industry: High-speed bucket elevators play a vital role in cement plants for conveying raw materials and finished products.

Low-Speed Bucket Elevators:

- Food Processing: Low-speed bucket elevators are widely used in food processing plants for handling delicate food products such as fruits, vegetables, and nuts.

- Pharmaceuticals: In pharmaceutical manufacturing, low-speed bucket elevators are utilized for the gentle handling of tablets, capsules, and other medicinal products.

- Chemical Industry: Low-speed bucket elevators find applications in the chemical industry for transporting fragile chemicals and powders without degradation.

Conclusion

In conclusion, the choice between high-speed and low-speed bucket elevators depends on various factors such as material characteristics, throughput requirements, and product integrity concerns. While high-speed bucket elevators offer greater throughput capacity and efficiency, they may not be suitable for handling fragile materials prone to degradation.

On the other hand, low-speed bucket elevators provide gentle handling and are ideal for delicate products that require careful transport. By understanding the distinct features and applications of high-speed and low-speed bucket elevators, industries can make informed decisions to optimize material handling processes and ensure product quality and integrity.