In the world of industrial automation, feeders play a crucial role in the efficient movement of materials. Two popular types of feeders are vibratory feeders and centrifugal feeders.

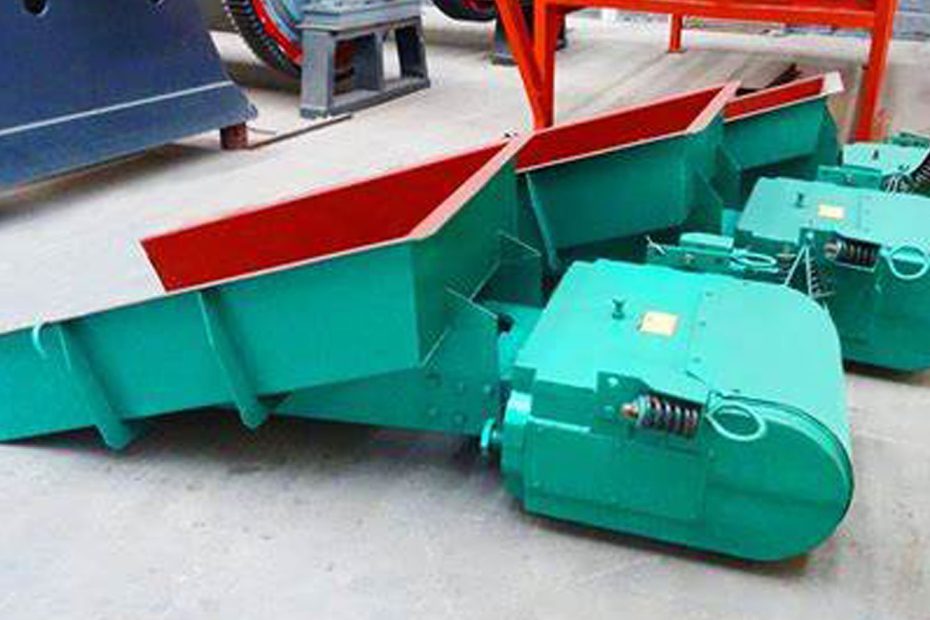

Understanding Vibratory Feeders

Vibratory feeders are devices that use vibrations to move materials along a conveyor belt. They consist of a bowl, a base, and an electromagnetic coil. The bowl is mounted on the base and contains the material to be fed. The electromagnetic coil generates vibrations, which are transmitted to the bowl, causing the material to move along the conveyor belt.

working principle

When the electromagnetic coil is energized, it generates a magnetic field that causes the bowl to vibrate. This vibration moves the material along the conveyor belt, where it can be collected and processed. Vibratory feeders can be adjusted to control the amplitude and frequency of the vibrations, allowing for precise control over the movement of materials.

Advantages of Vibratory Feeders

One of the main advantages of vibratory feeders is their ability to handle a wide range of materials, including powders, granules, and even fragile items. They are also highly efficient, with minimal energy consumption and low maintenance requirements. Additionally, vibratory feeders can be easily integrated into existing production lines, making them a versatile solution for a variety of applications.

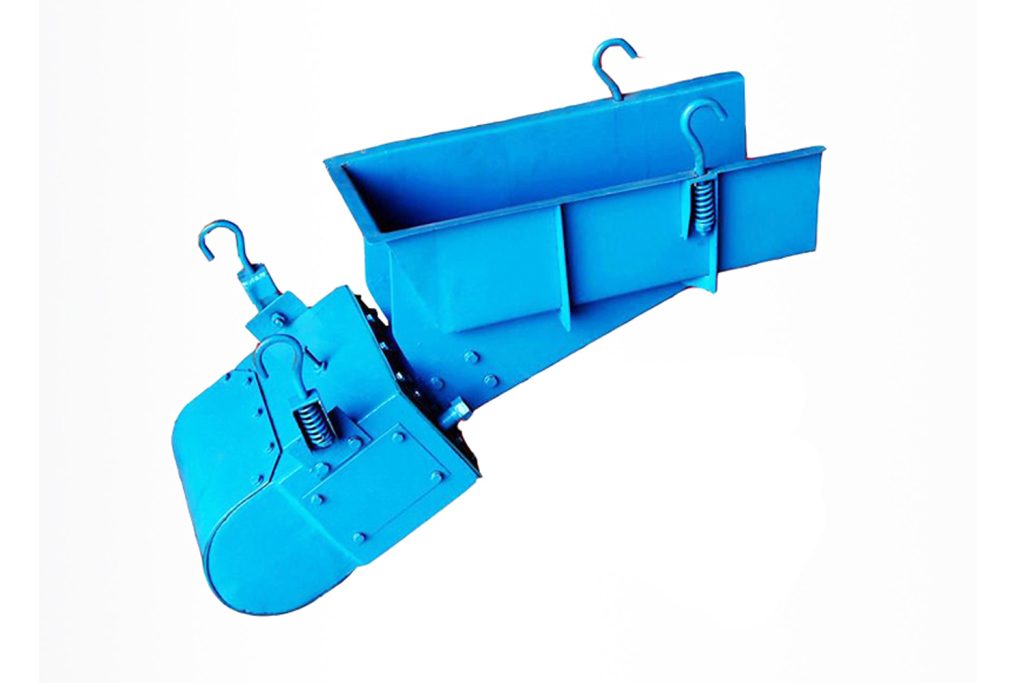

Understanding Centrifugal Feeders

Centrifugal feeders, also known as rotary feeders, are devices that use centrifugal force to move materials along a conveyor belt. They consist of a bowl, a base, and a rotating disc. The bowl is mounted on the base and contains the material to be fed. The rotating disc generates centrifugal force, which causes the material to move along the conveyor belt.

working principle

When the rotating disc is energized, it generates centrifugal force that causes the material to move along the conveyor belt. The speed of the disc can be adjusted to control the movement of materials, allowing for precise control over the feeding process. Centrifugal feeders are also highly efficient, with minimal energy consumption and low maintenance requirements.

Advantages of Centrifugal Feeders

One of the main advantages of centrifugal feeders is their ability to handle a wide range of materials, including powders, granules, and even fragile items. They are also highly efficient, with minimal energy consumption and low maintenance requirements. Additionally, centrifugal feeders can be easily integrated into existing production lines, making them a versatile solution for a variety of applications.

Comparative Analysis : Vibratory Feeder vs. Centrifugal Feeder

Both vibratory feeders and centrifugal feeders have their advantages and disadvantages. Vibratory feeders are highly efficient, with minimal energy consumption and low maintenance requirements. They can handle a wide range of materials and can be easily integrated into existing production lines. However, they may not be suitable for handling very large or heavy materials.

On the other hand, centrifugal feeders are highly efficient and can handle a wide range of materials. They are also highly versatile and can be easily integrated into existing production lines. However, they may not be suitable for handling very small or fragile materials.

Applications of Vibratory and Centrifugal Feeders

Vibratory feeders are commonly used in industries such as food processing, pharmaceuticals, and automotive manufacturing. They are ideal for handling materials that require gentle handling, such as powders, granules, and fragile items.

Centrifugal feeders are commonly used in industries such as plastics, chemicals, and electronics. They are ideal for handling materials that require high-speed feeding, such as small parts, fasteners, and electronic components.

Conclusion

In conclusion, both vibratory feeders and centrifugal feeders have their advantages and disadvantages. Vibratory feeders are highly efficient and can handle a wide range of materials, but may not be suitable for handling very large or heavy materials. Centrifugal feeders are highly efficient and can handle a wide range of materials, but may not be suitable for handling very small or fragile materials. As with any industrial equipment, the choice between vibratory feeders and centrifugal feeders will depend on the specific requirements of the application.