In the realm of industrial automation, feeders play a pivotal role in the efficient and smooth operation of production processes. Two popular types of feeders are electromagnetic vibratory feeders and pneumatic feeders. Both have distinct advantages and applications, and choosing the right one for a specific task can significantly impact productivity and efficiency.

Electromagnetic Vibratory Feeder vs. Pneumatic Feeder: Working Principles Comparative

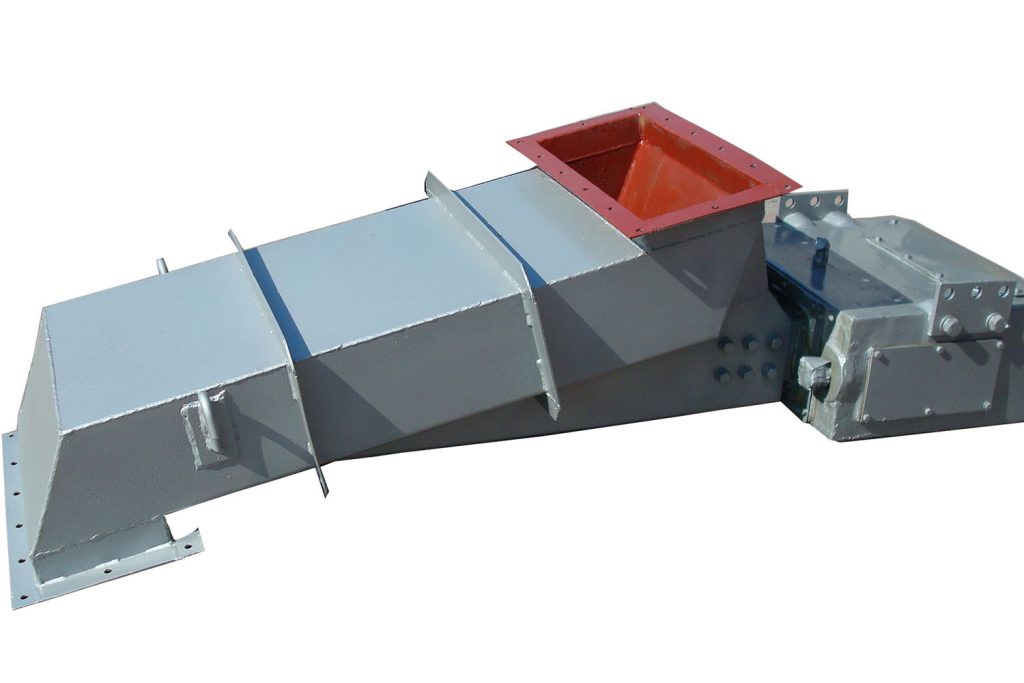

Electromagnetic Vibratory Feeder : An electromagnetic vibratory feeder consists of a tray made of mild steel and a body housing the electromagnet. The tray, which is attached to the body, vibrates due to the electromagnetic coil, creating a controlled flow of material. This vibration is achieved by varying the frequency and amplitude of the electromagnetic coil. The amplitude determines the intensity of the vibrations, while the frequency controls the rate at which the material is fed.

Pneumatic Feeder : A pneumatic feeder, on the other hand, uses compressed air to move materials. It consists of a hopper that holds the material, a nozzle or valve to control the flow of air, and a conveyor to transport the material. When the compressed air is released, it creates a vacuum that draws the material into the nozzle, where it is then propelled forward by the force of the air.

Electromagnetic Vibratory Feeder vs. Pneumatic Feeder: Applications Comparative

Electromagnetic Vibratory Feeder : Electromagnetic vibratory feeders are commonly used in industries such as pharmaceuticals, food processing, and packaging. They are ideal for handling delicate materials that require gentle handling, such as powders, granules, and small parts. They are also suitable for applications where precise control over the feed rate is required.

Pneumatic Feeder : Pneumatic feeders are widely used in industries such as mining, construction, and agriculture. They are ideal for handling bulk materials that are difficult to handle with other types of feeders, such as large rocks, gravel, and sand. They are also suitable for applications where high-speed feeding is required.

Electromagnetic Vibratory Feeder vs. Pneumatic Feeder: Advantages Comparative

Electromagnetic Vibratory Feeder

- Precise control over the feed rate

- Gentle handling of delicate materials

- Low maintenance requirements

- Quiet operation

Pneumatic Feeder

- High-speed feeding

- Can handle a wide range of materials

- Can be used in harsh environments

Electromagnetic Vibratory Feeder vs. Pneumatic Feeder: Limitations Comparative

Electromagnetic Vibratory Feeder

- Limited to handling materials that are not too heavy or abrasive

- Can be affected by external factors such as temperature and humidity

Pneumatic Feeder

- Requires a constant supply of compressed air

- Can be noisy

- Not suitable for handling delicate materials

Conclusion

In conclusion, both electromagnetic vibratory feeders and pneumatic feeders have their own set of advantages and limitations. The choice between the two depends on the specific requirements of the application. If precise control over the feed rate and gentle handling of materials are required, an electromagnetic vibratory feeder would be the ideal choice.

On the other hand, if high speed feeding and the ability to handle a variety of materials are more important, then a pneumatic feeder would be a better choice. Ultimately, both types of feeders play a vital role in the efficient operation of industrial processes, and choosing the right vibratory conveyor system can significantly impact productivity and efficiency.