Vibratory belt conveyors have become indispensable equipment in bulk material handling processes. These durable conveyance systems are designed to efficiently move products and can be customized to meet the specific manufacturing needs of various industries.

With features like safety side panels, counter-rotating motors, and specialized applications for concrete molds, vibratory belt conveyors offer a versatile and reliable solution for seamless material transportation.

Customizable Vibratory Belt Conveyors

One of the key advantages of vibratory belt conveyors is their ability to be tailored to meet the unique requirements of different manufacturing operations. These conveyors come in various lengths, allowing them to be adjusted based on the facility layout and production needs. Whether a short-distance material transfer or a longer series of tandem-mounted units is necessary, vibratory belt conveyors can be adapted to suit the specific application.

Design Features for Safety and Efficiency

Vibratory belt conveyors are engineered with safety and efficiency in mind. The inclusion of safety side panels or guards ensures that operators are protected from potential hazards while maintaining a clear view of the material flow. To power the conveyor, two counter-rotating motors are utilized, providing optimal balance and minimizing vibration-related issues. These motors typically operate at 230/460 volts, 3 phase, and 60 cycles, catering to different power supply configurations.

Additionally, for facilities requiring compliance with specific safety standards, vibratory belt conveyors can be equipped with UL controls, offering an extra layer of assurance in safety and reliability.

Versatility with Multiple Vibratory Tables

A notable advantage of vibratory belt conveyors is their ability to accommodate up to four vibratory tables. These tables enhance the efficiency of material handling by further aiding in the movement and separation of bulk products. Industries dealing with various types of materials, such as food processing, mining, and agriculture, benefit from this versatility as it allows for more controlled and optimized material flow throughout the production line.

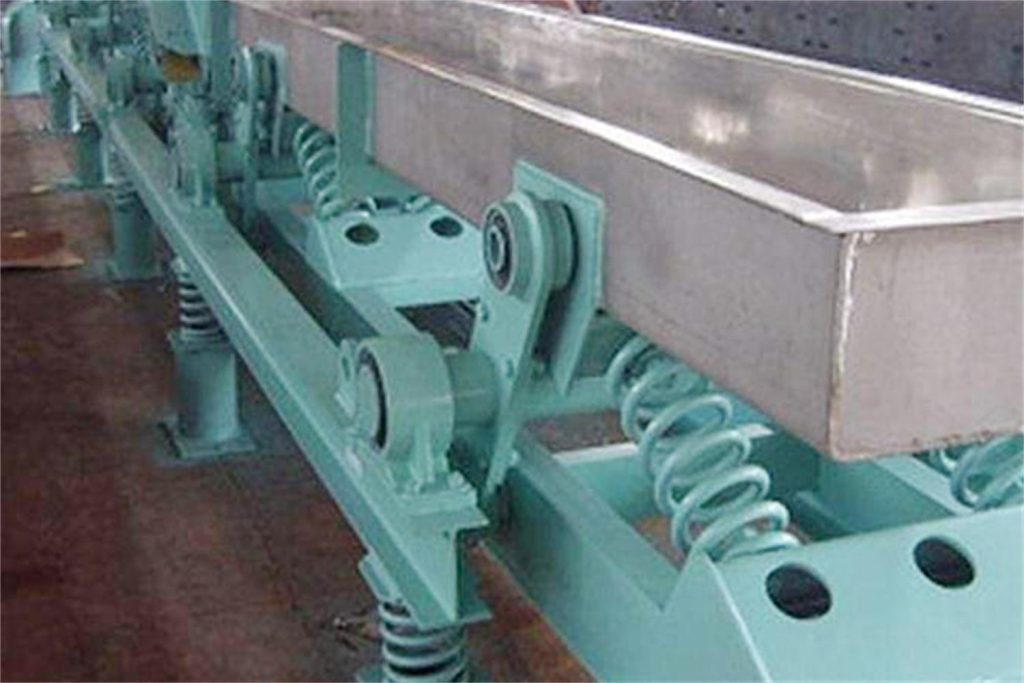

Tubular Trough Construction for Durability

To ensure the durability and longevity of vibratory belt conveyors, they are constructed with tubular troughs. This design choice offers several advantages, including increased strength and resistance to wear and tear. The tubular troughs also contribute to better containment of materials, preventing spillage and minimizing the impact on the surrounding environment.

Specialized Applications for Concrete Molds

In the concrete molding industry, continuous fill lines are essential for maintaining smooth and efficient production processes. However, air bubbles can be a persistent challenge during concrete pouring. Vibratory belt conveyors offer an innovative solution to this problem. By incorporating vibration into the conveyor system, air bubbles are minimized, ensuring a more consistent and high-quality concrete molding process.

Conclusion

In summary, vibratory belt conveyors are vital components in bulk material handling operations, providing a customizable and durable solution for transporting products across various industries. Their design features, such as safety side panels, counter-rotating motors, and the option for multiple vibratory tables, ensure efficient and safe material flow. Moreover, the application of vibratory belt conveyors in the concrete molding industry showcases their adaptability in addressing specific challenges and enhancing manufacturing processes.

With the ability to tailor these conveyors to meet the unique needs of different facilities, it is no wonder they have become a go-to choice for many manufacturing operations. By incorporating vibratory belt conveyors into their workflows, businesses can experience increased productivity, reduced downtime, and improved overall efficiency in their bulk material handling processes.