A vibrating conveyor is a continuous conveying machine that uses an exciter to vibrate the material trough, so that the material in the trough slides or moves in a certain direction.

The material is transported in a projectile state in the vibrating conveyor, which causes less wear on the conveying trough. It can transport materials of various particle sizes, and can carry out closed transportation of hot, flammable, explosive, toxic, and dusty materials, which is beneficial to environmental protection.

The vibrating conveyor is mainly used to transport loose block or granular materials in horizontal or small inclination conditions, and can also transport powdered materials with a particle size of no more than 74μm.

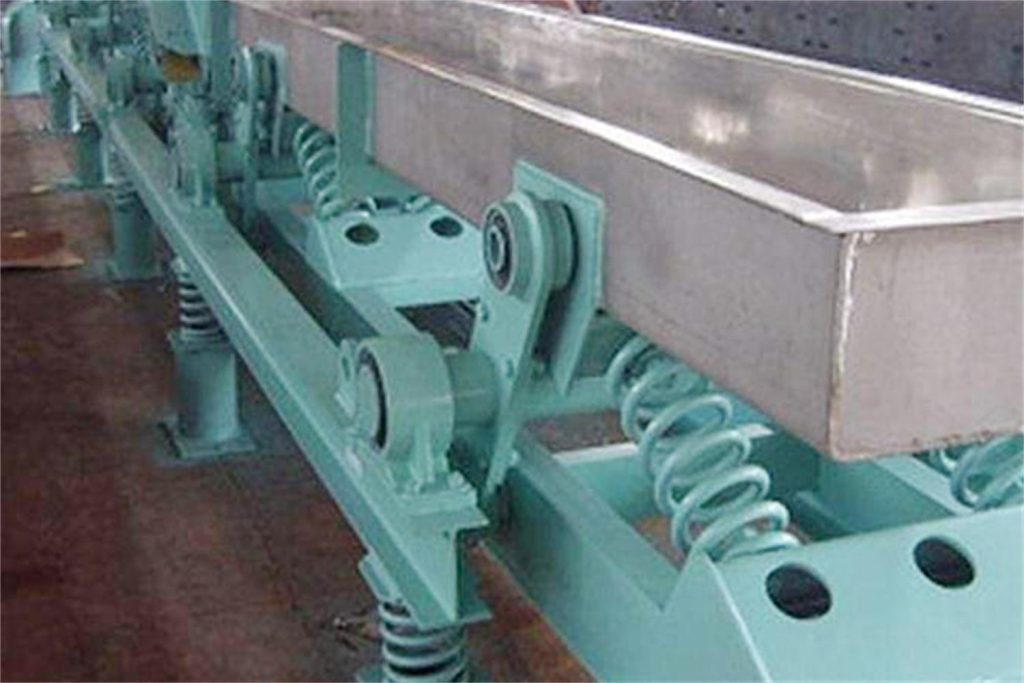

The vibrating conveyor is mainly composed of load-bearing components, elastic elements, and exciters. This model has the advantages of simple structure, easy installation and maintenance, low energy consumption, no dust spillage, and low noise.

After the installation of the vibration conveyor is completed, five conditions must be met during the test run

- All relevant electrical construction and automatic control construction are completed and meet the requirements;

- All lubrication points are filled with lubricating grease as required;

- The vibrating conveyor and the passages are cleaned;

- The electrical system, safety interlocking device, braking device, operation control system and signal system should be checked by simulation or operation, and their working performance should be sensitive, correct and reliable;

- Turn each motion mechanism to make the input and output shafts of the transmission system rotate one circle, and there should be no jamming phenomenon; the rotation direction of the motor should be consistent with the running direction of the conveyor.

Conclusion

The vibration conveyor has a simple structure, low energy consumption and convenient maintenance. However, it is necessary to maintain and maintain the vibration conveyor frequently to increase the service life of the equipment and reduce the failure rate.

Vibrating conveyor system can be widely used in the transportation of powdered and granular materials in metallurgy, coal, building materials, chemicals, glass, electricity, machinery, grain and other industries.