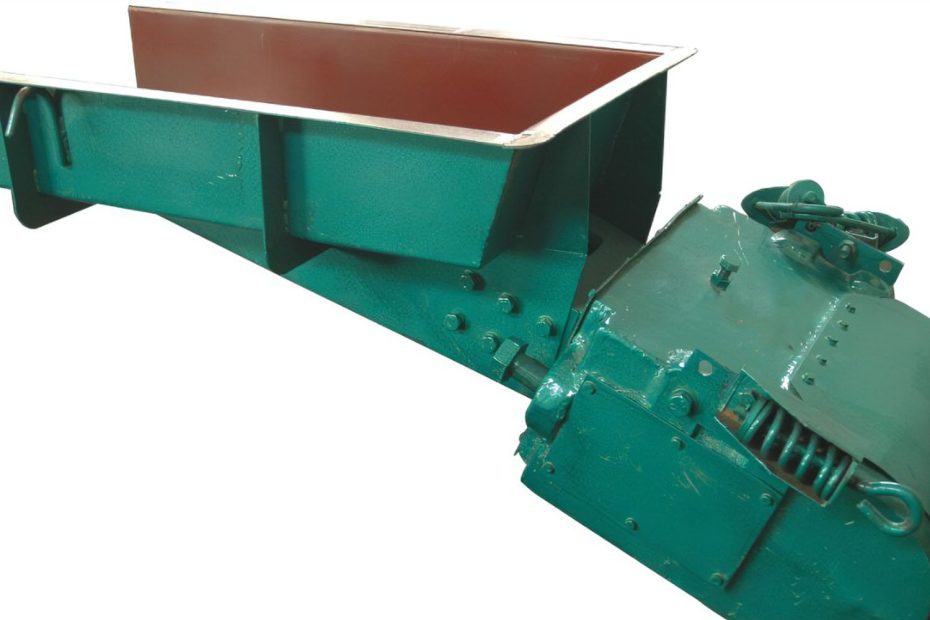

Vibrating feeders are devices that utilize the principle of vibration for material feeding. Compared to traditional feeding equipment such as rotary feeders, pendulum feeders, and plate feeders, vibrating feeders boast high throughput, low energy consumption, small size, simple structure, and reliable operation. They offer a series of advantages including easy maintenance, feasibility for automated control, and have found extensive applications in sectors such as mining, metallurgy, mechanical manufacturing, coal, chemical industry, building materials, as well as food and light industries.

For instance, vibrating feeders are used for discharging from silos, feeding belt conveyors, bucket elevators, crushers, ball mills, providing quantitative feeding in packaging machine systems, and ensuring uniform continuous feeding in batching systems.

Vibrating feeders accommodate a wide range of materials, from granular materials with a particle size of 0.1 millimeters or more, to general bulk materials, and even large blocks ranging up to 400-500 millimeters or more, and even massive materials exceeding one meter in size. Additionally, they can convey powdered materials (for powdery materials prone to flying, the supporting components should be made into a sealed structure). With appropriate measures, they can also handle high-temperature materials and highly corrosive materials.

Types of Vibrating Feeders

There are various forms of vibrating feeders. Based on the excitation mode, they can be primarily divided into three categories:

- Electromagnetic vibrating feeders

- Self-synchronous vibrating feeders

- Inertial resonance vibrating feeders

Characteristics of Vibrating Feeders

Electromagnetic vibrating feeders and inertial resonance vibrating feeders belong to the near-resonance type vibratory machines, both operating in a low subcritical near-resonance state, requiring minimal excitation force. Self-synchronous vibrating feeders, on the other hand, operate far beyond the resonance state, belonging to non-resonant vibratory machines, making it easier to achieve stable amplitudes.

Electromagnetic vibrating feeders are characterized by the absence of rotating parts and lubrication points. They allow convenient and stepless adjustment of the feeding amount during operation and are easily adaptable to automatic feeding control. Additionally, they feature simple structures and lighter weights.

Compared to forced synchronous vibrating feeders, self-synchronous vibrating feeders have simpler structures, facilitating the design and manufacture of multi-drive structural forms. This aspect is highly advantageous for designing and manufacturing large vibrating feeders and those with longer troughs. Similar to electromagnetic vibrating feeders, they also offer the advantages of low operating frequencies and large amplitudes, resulting in higher conveying speeds. Moreover, they incur lower maintenance costs and generate less noise. Consequently, these vibrating feeders have gained widespread applications in recent years.

Conclusion

Vibrating feeders, with their diverse types and advantageous characteristics, serve as indispensable equipment in various industries, catering to the needs of efficient material handling and processing. Their versatility, reliability, and efficiency make them integral components across different sectors, driving productivity and facilitating automation in material handling processes.