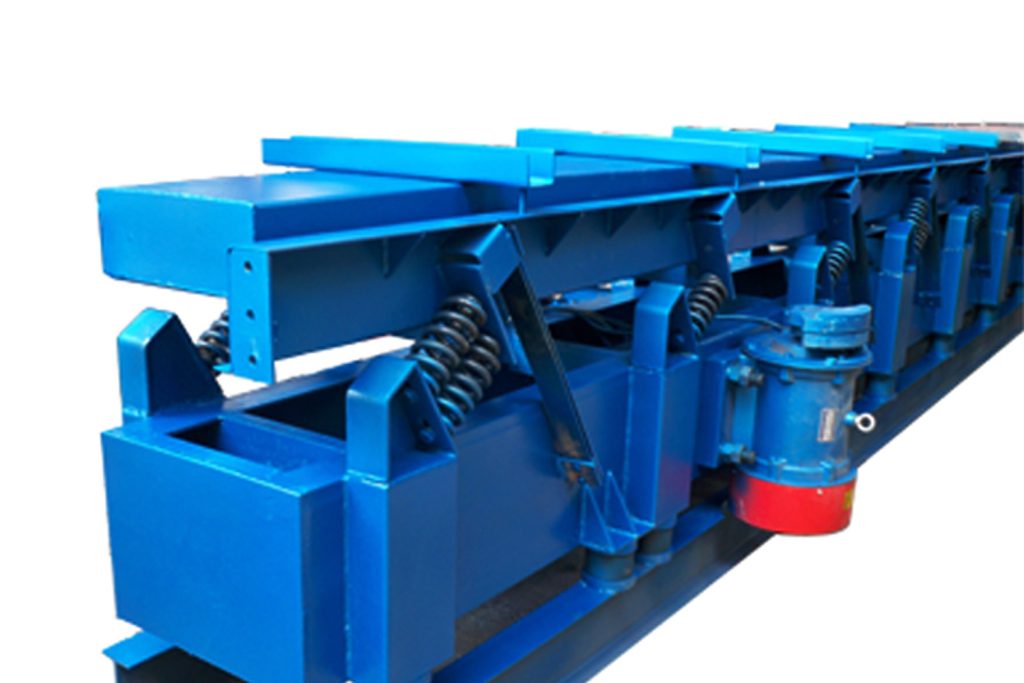

The vibration conveying system is a continuous conveying system that uses an exciter to vibrate the material trough, thereby causing the material in the trough to slide or move in a certain direction. Vibrating conveyors are mainly used to transport loose block or granular materials at a horizontal or small inclination angle.

The vibration conveying system has a simple structure, low energy consumption, and no dust spillage. It is widely used for conveying powdery and granular materials in metallurgy, coal, building materials, chemicals, food and other industries.

The Diverse Range of Mechanical Conveying Systems

Mechanical conveyors have experienced significant advancements, offering a wide range of options for material handling. Let’s explore some of the prominent types:

- Screw Conveyors: Rooted in history, screw conveyors are ideal for short horizontal runs in straight lines. However, their ability to convey up an incline is limited, making them unsuitable for scenarios with significant elevation changes.

- Belt Conveyors: Belt conveyors cater to a broad scale of operations, ranging from conveying a few kilograms per hour to extreme rates of 10,000 tons per hour or more. Their scalability makes them versatile, but the design details vary significantly based on the application.

- Bucket Elevators: When substantial elevation is required, bucket elevators come into play. They efficiently handle vertical conveying tasks that screw and belt conveyors might struggle with.

Factors for diversified selection of vibrating conveyors

- Diverse Applications: Each application demands specific conveyor characteristics, such as conveying distance, inclination requirements, and material properties.

- Scalability of Operations: Different industries and processes necessitate conveyors that can handle various conveying rates, from small-scale to heavy-duty operations.

- Innovative Solutions: Overcoming the limitations of conventional conveyors has led to the development of innovative designs, addressing challenges like inclined or vertical conveying.

Top 5 Factors to Consider when Selecting vibrating Conveyor

Choosing the right conveyor for a particular application requires careful consideration of various factors. Understanding the specific needs of the material handling process is crucial.

- Material Properties: The characteristics of the material, such as bulk density, particle size, and flowability, play a critical role in determining the suitable conveyor type.

- Conveying Distance and Inclination: The distance the material needs to be conveyed and any required incline or decline angles impact the choice of conveyor.

- Throughput Requirements: Determining the required conveying rate is essential in selecting a conveyor with the appropriate capacity.

- Environmental Factors: Considerations like temperature, humidity, and presence of corrosive materials influence conveyor material selection.

- Operating Parameters: Specific industry standards, hygiene requirements, and safety considerations must be addressed when choosing a conveyor.

Conclusion

The history of mechanical conveying has witnessed remarkable advancements, providing industries with a diverse range of conveyor options to optimize material handling processes. From the humble Archimedean screw to modern-day belt conveyors, bucket elevators, and innovative designs like pipe conveyors, each type serves specific applications.

The wide variation in conveyor types and designs caters to different material handling demands, ensuring efficiency and adaptability across industries. The key to selecting the most appropriate conveyor lies in understanding material properties, conveying requirements, and environmental factors, allowing businesses to make informed decisions and elevate their material handling efficiency. As technology continues to evolve, so will the realm of mechanical conveyors, paving the way for even more efficient and innovative solutions in the future.