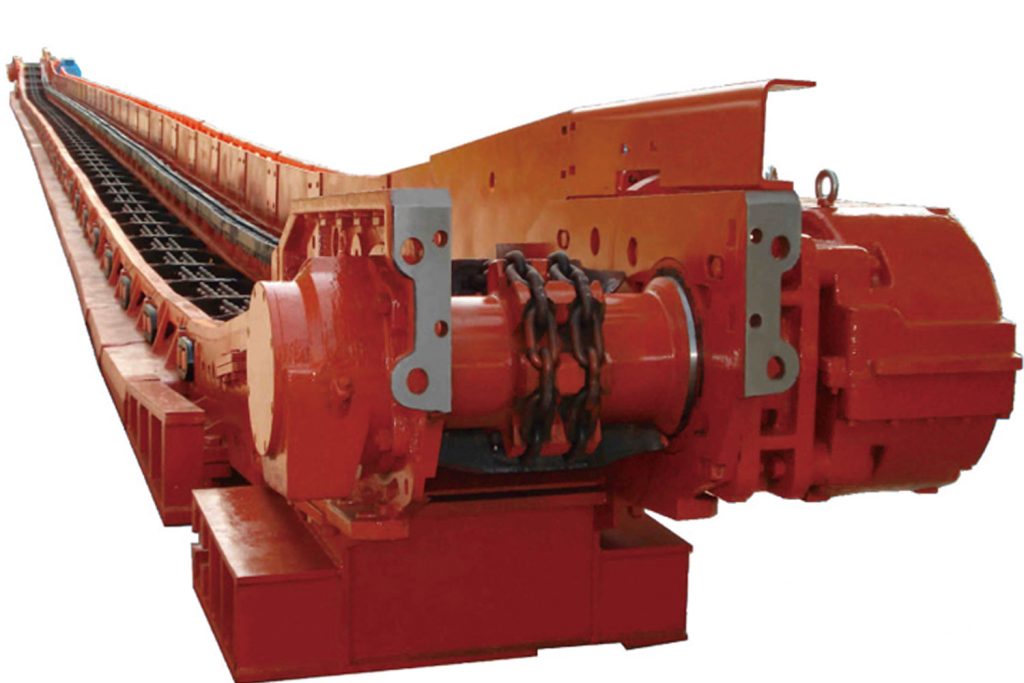

Scraper conveyor is a common material conveying equipment, which is used for conveying equipment on horizontal or slightly inclined process production lines.

Scraper conveyor is an efficient, reliable, durable and flexible material conveying equipment. It is widely used in material transportation in various industrial fields.

Material conditions have three major impacts on the conveying capacity of scraper conveyors

The scraper conveyor is a kind of material conveying equipment widely used in industrial production lines. It can convey various solid materials. Therefore, in the process of conveying different materials, the material condition has a great influence on the conveying capacity of the scraper conveyor.

1. Material particle size

The particle size of the material refers to the particle size of the material before conveying, and it is also one of the important parameters affecting the conveying capacity of the scraper conveyor. Generally, the smaller the particle size of the material, the larger its specific surface area, the thicker the area in contact with the conveyor, and the greater the resistance. Therefore, for materials with small particle size, it is usually necessary to reduce the conveying speed to avoid excessive resistance loss.

For materials with larger particle size, the conveying rate and conveying capacity can be improved by adjusting the conveying speed and the size of the inlet and outlet of the hopper, so that it has greater conveying capacity.

2. Material adhesion

Material adhesion refers to the degree of adhesion between sand particles in the material. Viscous materials tend to stick to the conveying mechanism during the conveying process, resulting in sticking and jamming. This stickiness will seriously affect the conveying capacity of the scraper conveyor, and even block the normal operation of the conveying mechanism.

For this situation, a conventional solution is to mix highly viscous and viscous materials with a certain amount of additives to improve the fluidity of the materials. For the transportation of viscous materials, such as rubber, etc., it can also be melted by heating, or the conveying mechanism can be finely designed to reduce its adhesion.

3. Material density

The material density refers to the ratio of the volume to the weight of the material. The material with high density has a higher weight, and the output force will be greater when passing through the conveying mechanism, which will affect the conveying capacity of the scraper conveyor. T herefore, for materials with high material density, it is necessary to reduce the material feeding in an appropriate amount, so as not to cause overload damage to the structural performance of the scraper conveyor.

At the same time, when the material density is low, the conveying capacity of the scraper conveyor will be relatively low. Therefore, it is necessary to increase the conveying capacity of the scraper conveyor by increasing the conveying speed and increasing the feeding volume.

In summary

There is a complex interplay between material condition and conveying capacity. In order to ensure the normal operation of the scraper conveyor, it is necessary to make corresponding adjustments and treatments for different material conditions to meet the production needs.