Vibrating conveyors play a pivotal role in modern industrial processes, aiding the movement of various materials efficiently. Among these, the single-mass vibrating conveyor stands out for its unique structure and distinctive characteristics, making it a valuable component in many applications.

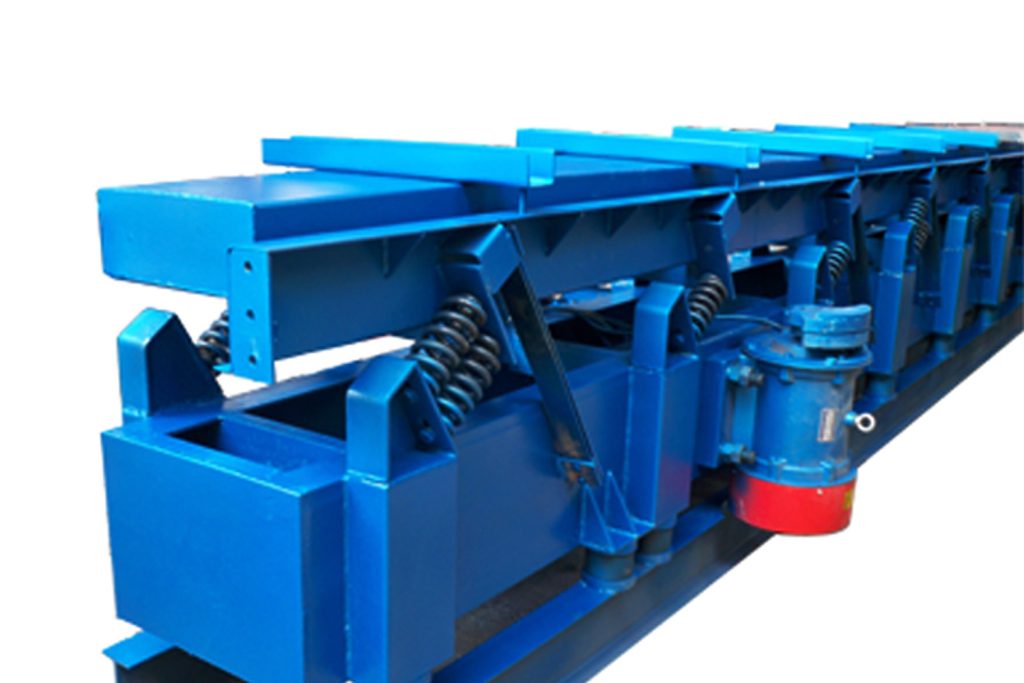

The single-mass vibratory conveyor is a mechanical apparatus consisting of several components, including the trough, elastic linkage transmission, main vibration spring, guide rods, and fixed frame.

Components and Functionality

Trough Body

The trough body is supported by spiral springs and guide rods set at a 60-degree angle (can be adjusted to 45 or 30 degrees depending on the application). The guide rods dictate the direction of vibration of the trough. The spiral springs regulate the near-resonant operating point, adjusting the ratio between the working frequency (f) and the system’s natural frequency (f₀).

The core of the conveyor, the trough body, is designed for optimal material transport. It consists of a sturdy base that supports the material and facilitates its movement. The shape and design of the trough influence the direction and efficiency of material conveyance.

Elastic Linkage Transmission

The vibration conveyor operates in a state of near-resonance. As the main vibration spring deforms, it stores energy which is then released as the deformation reduces. However, during operation, a portion of energy is lost and needs to be replenished by the exciter or transmission components. An electric motor mounted on a fixed base undergoes a reduction through a triangular belt mechanism. This motion is then transferred to an eccentric shaft which converts rotary motion into reciprocating motion through connecting rods.

At the heart of the conveyor’s operation lies the elastic linkage transmission system. This mechanism converts rotary motion from a motor into reciprocating linear motion. Through a system of connecting rods and springs, the motor’s energy is transformed into the necessary vibrations that propel the material forward.

Main Vibration Spring

The connecting rods are linked to the trough via rubber springs, also known as connecting rod springs. These springs transmit the exciting force to the trough. The role of these springs is to minimize the starting torque and prevent the transmission components from experiencing impact loads, thus enabling the system to achieve elastic vibration.

The main vibration spring is a crucial element that stores and releases energy during operation. As the conveyor moves, the spring absorbs and stores potential energy when compressed and then releases it as the spring extends back to its original position. This cyclic energy transfer propels the material along the conveyor.

The vibrating conveyor usually works in a near-resonance state. When the main vibration spring deforms, it stores energy and releases energy when the deformation decreases. However, during the working process of the vibrating conveyor, part of the energy will be lost, which must be replenished by the exciter or the transmission part. The motor mounted on the fixed base frame is decelerated by the V-belt, and the motion is transmitted to the eccentric shaft. The rotational motion of the shaft is converted into the reciprocating motion of the connecting rod, and then through the rubber spring between the connecting rod and the tank, that is, the connecting rod spring, The exciting force is transmitted to the tank body, and the function of the connecting rod spring is to reduce the starting torque and avoid the impact load on the transmission part, and make the system realize elastic vibration.

Guide Rods and Direction Control

Guide rods are strategically placed to influence the direction of vibration. By adjusting the angles of these rods, the direction of material movement can be finely tuned. This feature enhances the conveyor’s adaptability to different material transport scenarios.

Characteristics of the single-mass vibrating conveyor

Simplicity of Construction: This conveyor’s design is straightforward, making it easy to manufacture and install.

- Efficient Material Movement: The single-mass vibrating conveyor excels in its ability to move a wide range of materials. Whether it’s delicate food products or robust industrial components, the conveyor can transport them with precision.

- Near-Resonant Operation: The conveyor operates near its resonant frequency, maximizing its efficiency. The use of the main vibration spring to regulate this frequency ensures that the conveyor operates at its optimal capacity, reducing energy wastage.

- Simplicity in Design: The straightforward design of the conveyor makes it relatively easy to manufacture and install. The integration of just a few key components simplifies maintenance and reduces the likelihood of breakdowns.

- Minimized Energy Loss: The cyclic nature of energy storage and release in the main vibration spring reduces energy loss during operation. This efficiency is crucial for reducing operational costs and increasing the lifespan of the conveyor.

- Foundation Requirements: Due to the fact that the fixed frame is directly anchored to a concrete foundation using anchor bolts, there is a substantial force transferred to the foundation. As a result, a sturdy foundation is imperative for proper operation. Consequently, this conveyor is not suitable for heavy troughs or high vibration accelerations.

- Dual Conveyor Configuration: To mitigate the dynamic loads transferred to the foundation, a dual conveyor configuration can be employed. Two vibratory conveyors, positioned front and rear, are driven by two sets of eccentric shafts phased at 180 degrees. This arrangement allows the dynamic loads transferred to the foundation to cancel each other out, although the inertial torque remains. To support such a conveyor, a few columns capable of resisting inertial torque are sufficient, allowing for installation at heights ranging from 5 to 6 meters.

Conclusion

The single-mass vibratory conveyor’s architecture is marked by its functional components, primarily the trough, elastic linkage transmission, and main vibration spring. Its simplicity in construction and the potential for dual conveyor configurations to minimize foundation loads are notable characteristics. Understanding its operational principles and structural features is essential for designing, constructing, and effectively implementing this type of conveyor system.