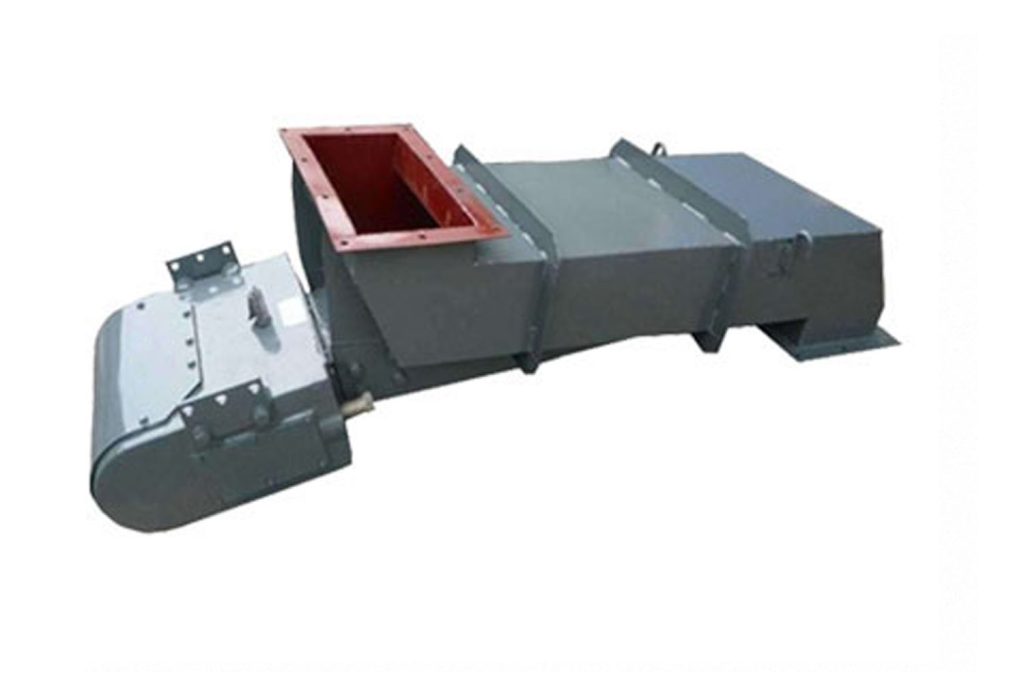

In the intricate dance of material handling within industrial processes, the electromagnetic vibrating feeder emerges as a key player. The electromagnetic vibrating feeder is small in size, light in weight, simple in structure, easy to install, has no rotating parts and does not require lubrication, is easy to maintain, and has low operating costs. The electromagnetic vibrating feeder can instantly change and open and close the material flow, so the feeding amount has high accuracy and can realize centralized control and automatic control of the production process.

At the core of an electromagnetic vibrating feeder lies the principle of electromagnetic induction. This device employs an electromagnetic coil and a corresponding armature to create vibrations. The alternating current in the coil generates a magnetic field, causing the armature to move, and subsequently, the feeder tray to vibrate.

Components Of Electromagnetic Vibrating Feeder

- Electromagnetic Coil : The electromagnetic coil is the powerhouse of the vibrating feeder. It converts electrical energy into mechanical energy, initiating the vibration process.

- Armature and Feeder Tray : Connected to the coil, the armature translates the magnetic force into mechanical motion, causing the feeder tray to vibrate. The tray, often customized to suit specific materials, then conveys the material forward.

How to adjust the feeding amount of electromagnetic vibrating feeder

The feeding amount of the electromagnetic vibrating feeder is achieved by changing the voltage across the coil. Under normal operating conditions of the vibrating feeder, adjust the amplitude. When the potentiometer is turned to a very large value, neither the amplitude nor the current reaches the rated value. Especially when the current is very small, you need to open the electromagnetic vibration control box and check whether the upper sliding arm of the resistor is loose. If the amplitude and current still do not reach the rated value after tightening, it means whether the upper sliding arm of the resistor is loose. Requires adjustment to achieve maximum amplitude and current rating.

1. Vibration Intensity Control

- Frequency Adjustment : The frequency of vibration is a critical parameter for controlling the feeding amount. Higher frequencies result in more rapid vibrations, increasing the amount of material conveyed. Conversely, lower frequencies reduce the vibration intensity, leading to a decreased feeding amount.

- Amplitude Regulation : Fine-tuning the amplitude allows for precise control over the intensity of vibrations. A higher amplitude results in more significant tray movements, facilitating a larger feeding amount. Adjusting the amplitude to a lower setting decreases the vibrational force, reducing the material flow.

2. Material Flow Adjustments

- Tray Inclination : The inclination of the feeder tray plays a crucial role in material flow. A steeper incline encourages faster material discharge, increasing the feeding amount. Conversely, a gentler incline slows down the material flow, reducing the feeding rate.

- Material Consistency Considerations : Understanding the characteristics of the material being handled is essential for accurate feeding amount adjustments. For cohesive or sticky materials, a gentler vibration setting and a shallower tray inclination may be preferable to prevent clogging.

Comparison of Vibration Parameters and Feeding Amount

| Vibration Parameter | Effect on Feeding Amount |

|---|---|

| Higher Frequency | Increased feeding amount |

| Lower Frequency | Decreased feeding amount |

| Higher Amplitude | Increased feeding amount |

| Lower Amplitude | Decreased feeding amount |

| Steeper Tray Inclination | Increased feeding amount |

| Shallower Tray Inclination | Decreased feeding amount |

Conclusion

In the grand symphony of industrial processes, the electromagnetic vibrating feeder orchestrates the harmonious movement of materials. Mastering the adjustment of the feeding amount is akin to conducting this symphony with precision.

From controlling vibration parameters like frequency and amplitude to considering material flow adjustments, the art of optimizing the feeding amount is a multifaceted endeavor. Industries that embrace these principles and adopt best practices ensure a seamless and efficient material handling experience, unlocking the full potential of the electromagnetic vibrating feeder.