Motor vibrating feeders play a crucial role in various industries, facilitating the smooth and efficient handling of materials. These devices are designed to convey bulk materials from one place to another through vibration.

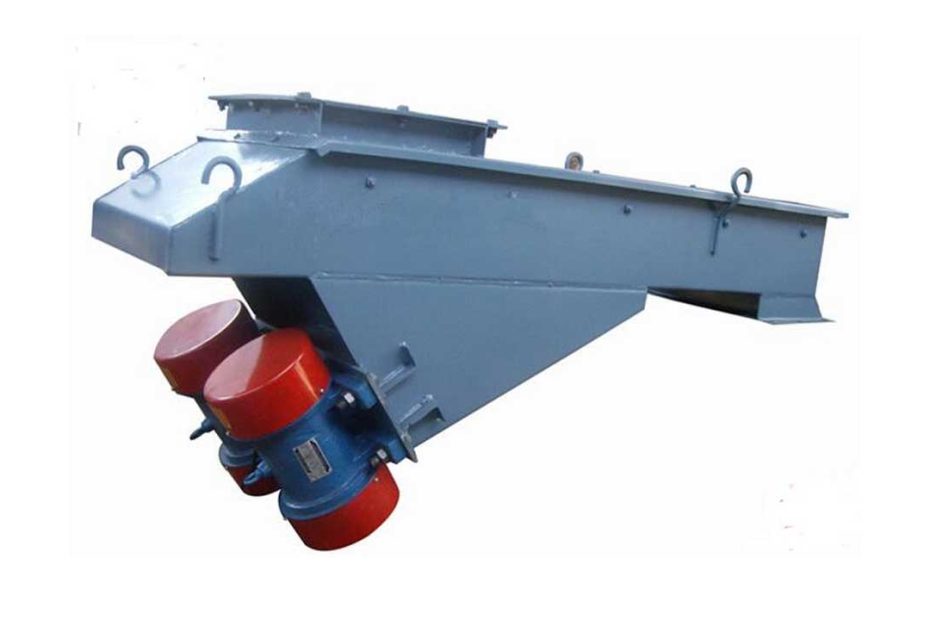

A motor vibrating feeder, also known as a vibratory feeder or vibration feeder, is a mechanical device used to transport bulk materials or parts from a storage hopper to a receiving device. It employs the principles of vibration to move materials along a conveyor or chute.

Top 3 key components of a motor vibrating feeder

- Motor : The motor generates the necessary vibrations to move materials. It is typically an electric motor that can be adjusted to control the amplitude and frequency of vibrations.

- Feeder Tray : The feeder tray is the surface upon which the materials rest. It is attached to the motor and vibrates as a result of the motor’s operation, propelling materials forward.

- Control Unit : A control unit regulates the motor’s speed and vibration intensity, allowing for precise material flow control.

Top 4 Advantages of Motor Vibrating Feeders in material handling processes

- Consistent Material Flow: The controlled vibrations ensure a steady and consistent flow of materials, preventing jams or blockages.

- Customizable Operation: Operators can adjust the vibration settings to accommodate various materials and feeding rates.

- Reduced Wear and Tear: Gentle, controlled conveying minimizes wear and tear on both the feeder and the conveyed materials.

- Low Maintenance: Motor vibrating feeders are relatively low-maintenance devices, requiring periodic inspections and lubrication.

Precautions When Starting a Motor Vibrating Feeder

Starting a motor vibrating feeder requires careful attention to ensure safe and efficient operation. Here are some essential precautions to consider:

- Inspect the Feeder : Before starting the feeder, perform a visual inspection to check for loose parts, damaged components, or any obstructions in the material path. Ensure that the feeder tray is clear and properly aligned.

- Lubrication : Lubricate all moving parts as per the manufacturer’s recommendations. Proper lubrication prevents excessive wear and maintains smooth operation.

- Electrical Connections : Verify that all electrical connections are secure and in good condition. Loose or damaged connections can lead to electrical hazards and operational issues.

- Safety Barriers : Install safety barriers or guards around the feeder to prevent unauthorized access and protect workers from moving parts during operation.

- Startup Sequence : Follow the manufacturer’s recommended startup sequence. This typically involves turning on the power, adjusting vibration settings, and gradually increasing the motor speed.

- Material Gradation : Ensure that the materials being fed have a consistent gradation to prevent uneven flow and potential blockages.

Common Materials Handled by Motor Vibrating Feeders

| Material | Characteristics |

|---|---|

| Coal | Granular, abrasive, variable particle size |

| Sand | Fine to coarse, free-flowing |

| Gravel | Coarse, irregular shapes, heavy |

| Food Products | Powdered, granulated, fragile |

| Pharmaceuticals | Fine powders, delicate granules |

| Chemicals | Various forms, corrosive properties |

| Plastic Pellets | Uniform, free-flowing |

| Metal Parts | Various sizes, may be sharp or irregular |

Conclusion

Motor vibrating feeders are a type of vibrating conveying system that are invaluable in the material handling process in various industries. Understanding their operation and taking precautions when starting are essential for safe and efficient use. By following proper procedures and maintenance guidelines, you can maximize the benefits of your motor vibrating feeder while ensuring workplace safety.