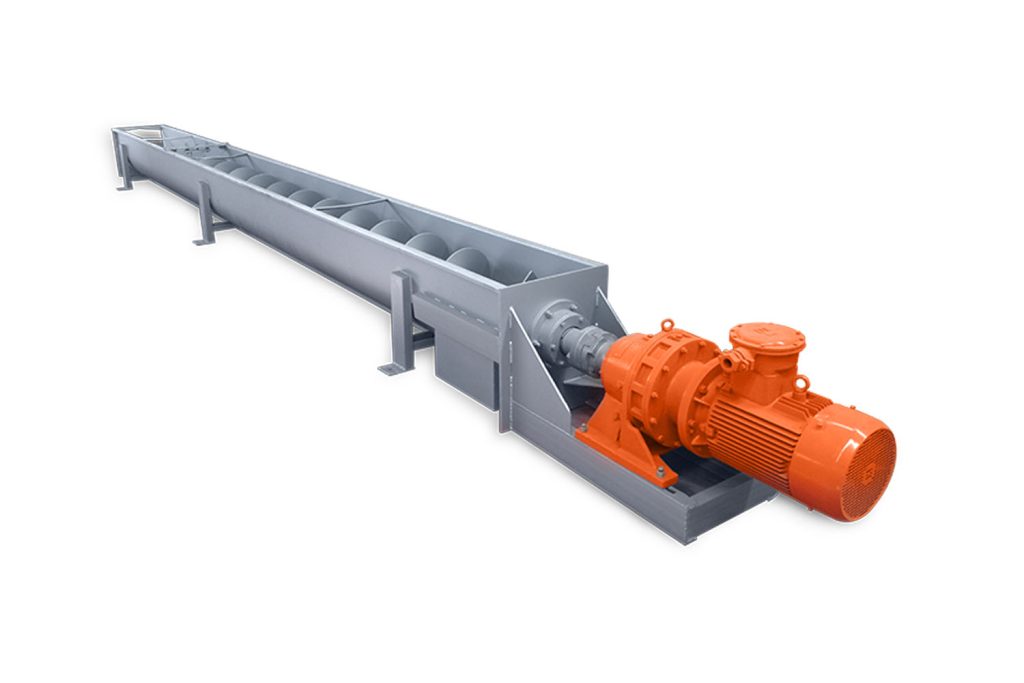

The screw conveyor is a general-purpose material conveying device, which mainly uses the thrust generated by the rotation of the screw blade to r ealize the transportation of the real material, and transports the material from the inlet to the outlet.

The double-shaft screw conveyor is a kind of horizontal double-axis symmetrical movement screw conveyor composed of two coaxial screw blades. It is mainly driven by the motor to make the two coaxial spiral blades rotate in reverse to convey materials.

The double-shaft screw conveyor can transport a variety of materials, such as powder, granular, solid and liquid materials, and has the characteristics of large conveying capacity, long conveying distance, various conveying directions, and good sealing performance.

3 main maintenance points of double shaft screw conveyor

Daily inspection of double shaft screw conveyor

- Check the motor and other external components to ensure that they function properly.

- Check the spiral blades, clean up the impurities and foreign objects in them, and avoid the wear or other failures of the spiral blades due to collision.

- Check the bearing and sealing device, add lubricating oil in time to ensure the normal sealing performance.

regular maintenance

Regular maintenance is an important guarantee to ensure the long-term stable operation of the double-axis screw conveyor. The regular maintenance includes:

- Disassemble the spiral blade, clean up the impurities and foreign matter in it, check whether it is damaged, and replace it in time.

- Check whether the bearing is in good condition, if necessary, add lubricating oil in time.

- Check the supporting bearings, and replace them in time if any signs of bearing wear are found.

- Check the transmission device, adjust the tightness of the transmission belt, and ensure the reliability of the transmission device.

problem solving

In the process of using the double-axis screw conveyor, some problems may occur, such as abnormal vibration, unexpected shutdown, abnormal sound or odor, etc. At this time, it needs to be dealt with in time. The specific treatment methods are as follows:

- According to specific problems, timely check and deal with the equipment.

- For some big problems or problems that cannot be handled, seek technical support from the equipment manufacturer or after-sales service provider in time.

Conclusion

Double-shaft screw conveyor is suitable for material transportation in chemical industry, environmental protection, food, building materials, metallurgy, mining, light industry and other industries, as well as processing and production processes in different fields.

During use, daily inspection and regular maintenance are required, and problems need to be dealt with in time. With the development of science and technology and the transformation of industrial production, the double-axis screw conveyor will be more widely used to provide a more complete and efficient solution for material transportation in the production process.