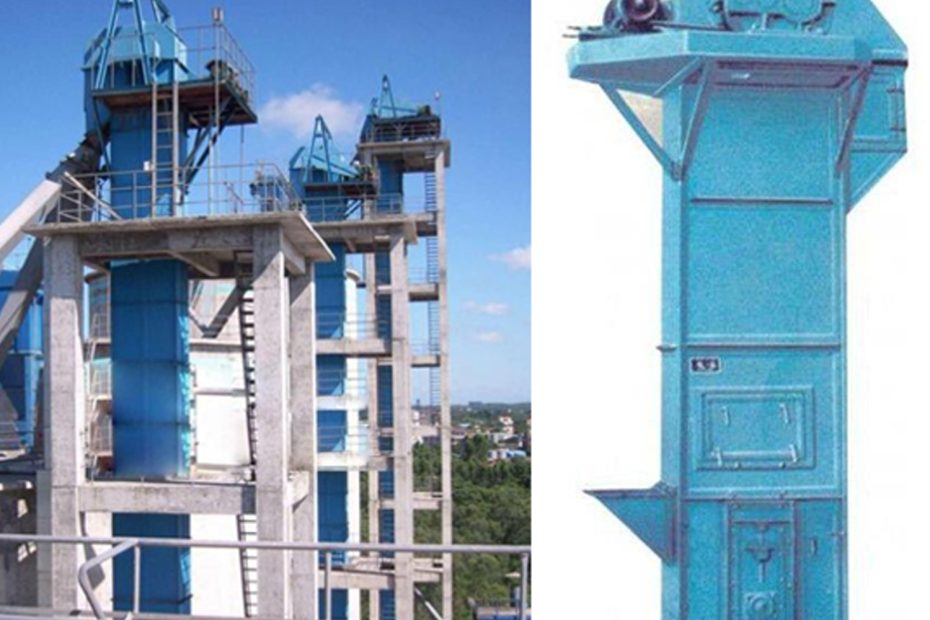

Bucket elevators are essential industrial equipment used for vertically conveying bulk materials. They find applications in various industries due to their efficiency in handling materials in a vertical direction.

Three Major Types of Bucket Elevators

1. Centrifugal Bucket Elevators

Centrifugal bucket elevators are one of the most common types, utilizing centrifugal force to propel materials at high speeds through the buckets. These elevators are ideal for handling fine and free-flowing materials such as grains, fertilizers, and small particles. The centrifugal force generated ensures a quick and efficient discharge of materials.

Applications

- Agricultural Sector: Centrifugal bucket elevators are widely used in the agricultural industry for handling grains, seeds, and fertilizers.

- Mining Industry: They are suitable for transporting various ores and minerals.

2. Continuous Bucket Elevators

Continuous bucket elevators operate at lower speeds than centrifugal ones and are designed to handle abrasive or sluggish materials. They use a series of buckets attached to a chain or belt, providing a continuous flow of material. This type is commonly used for abrasive or sticky materials that may damage a centrifugal elevator.

Applications

- Construction Industry: Continuous bucket elevators are employed for handling materials like sand, gravel, and concrete.

- Waste Management: They are suitable for transporting municipal solid waste and recycling materials.

3. Positive Discharge Bucket Elevators

Positive discharge bucket elevators are specifically designed to prevent material from being lost during the return journey. These elevators are suitable for fragile or friable materials that require gentle handling. The positive discharge mechanism ensures that materials are completely discharged at the destination.

Applications

- Food Processing: Positive discharge bucket elevators are used for handling delicate food products like nuts, seeds, and fragile snacks.

- Pharmaceutical Industry: They are suitable for transporting pharmaceutical powders and other sensitive materials.

Three Major Factors Influencing Bucket Elevator Selection

When choosing a bucket elevator for a particular application, several factors come into play. It’s crucial to consider the material characteristics, capacity requirements, and the physical properties of the installation site. The following factors play a significant role:

- Material Characteristics: The type, size, and characteristics of the material being transported influence the choice between centrifugal, continuous, or positive discharge bucket elevators.

- Capacity Requirements: Different types of bucket elevators offer varying capacities. Centrifugal elevators generally have higher capacities, while continuous elevators are suitable for lower capacities with a steady flow.

- Installation Site: The physical layout of the installation site, including the height and layout, affects the choice of bucket elevator type.

Comparative Look at Different Bucket Elevator Types

To provide a clearer understanding, let’s compare the key features of centrifugal, continuous, and positive discharge bucket elevators in the table below:

| Feature | Centrifugal Bucket Elevators | Continuous Bucket Elevators | Positive Discharge Bucket Elevators |

|---|---|---|---|

| Operating Speed | High | Low | Moderate |

| Material Handling | Free-flowing, Granular | Abrasive, Sticky | Delicate, Friable |

| Discharge Mechanism | Centrifugal Force | Continuous Flow | Positive Discharge |

| Application Industries | Agriculture, Mining | Construction, Waste Management | Food Processing, Pharmaceuticals |

Conclusion

In conclusion, the diverse range of bucket elevators caters to the specific needs of various industries. Understanding the differences between centrifugal, continuous, and positive discharge bucket elevators allows industries to make informed decisions based on their material handling requirements. Whether it’s handling delicate food products or transporting abrasive construction materials, there’s a bucket elevator type designed for the job. The versatility of these machines continues to contribute significantly to the efficiency of material handling processes across industries.