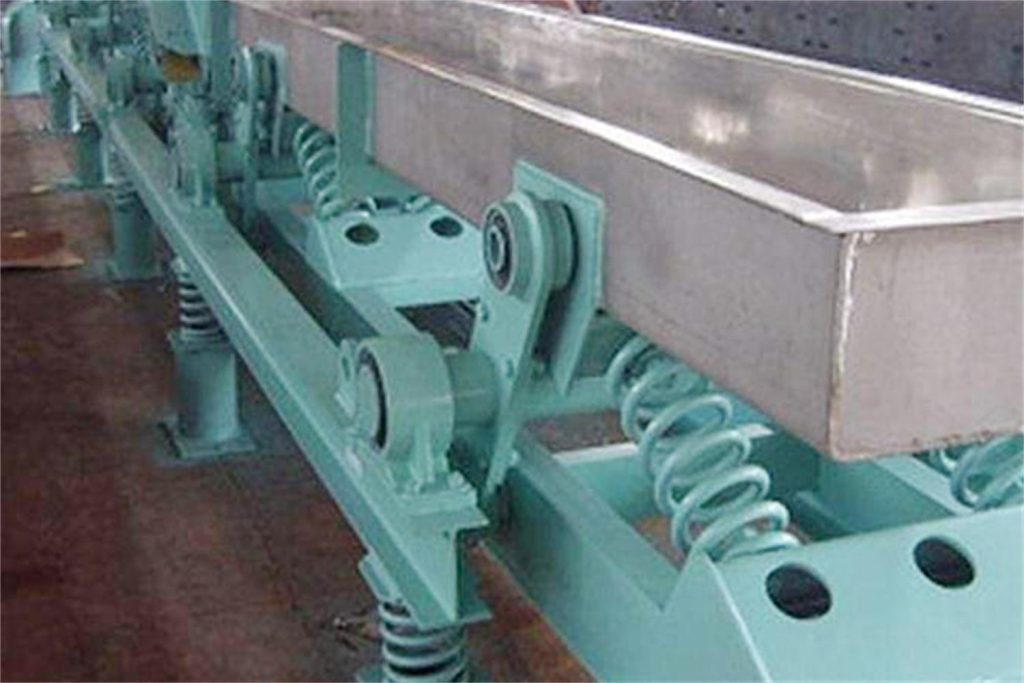

The vibrating conveyor is a continuous conveying machine that uses a vibrator to vibrate the trough, so that the material in the trough slides or is thrown in a certain direction.

The vibrating conveyor has a simple structure and can transport materials of various particle sizes. It can carry out closed transportation of hot, flammable, explosive, toxic and dusty materials, and can simultaneously complete screening, dehydration and cooling during the transportation process and other process operations.

A vibrating conveyor is a material conveying device that uses vibration force to convey materials from one point to another. It is very common in various fields, including mining, chemical industry, food, building materials, etc.

4 major reasons and solutions for poor sealing of vibrating conveyors

During the use of vibrating conveyors, various failures are often encountered, which will not only affect the continuity of production, but also affect the service life of the equipment.

4 reasons for poor sealing of vibrating conveyors

Like many other pieces of equipment, vibratory conveyors require proper sealing in order to operate properly. Poor seals usually occur due to:

- Damaged seals that do not fully cover the device;

- The vibrator is not installed tightly, resulting in gaps between the sealing materials;

- The interface of the feed port or the discharge port is not tightly fitted, resulting in leakage.

The method to solve the problem of poor sealing is as follows:

- Check and locate the leak, find out the damaged seal and replace it in time;

- Reinstall the vibrator and make sure that the sealing material fits well;

- Adjust the tightness of the feed port or discharge port interface, check the standard, and ensure that the interface fits firmly;

- Regularly clean foreign objects and sundries in the equipment to ensure the normal operation of the equipment.

In summary

There is no need to panic when the vibrating conveyor system encounters a failure. Instead, on the premise of correctly evaluating the problem, follow the relevant operating procedures, eliminate possible problems one by one, and have professional technicians repair and upgrade.

Only in this way can the normal operation of the vibrating conveyor be guaranteed and the continuity of production realized. During the long-term operation of the equipment, a maintenance and maintenance plan is formulated, and regular inspection and maintenance are carried out to ensure the normal operation of the equipment.