Vibrating conveyors are a vital component in various industrial processes, facilitating the efficient movement of bulk materials. However, they can sometimes exhibit excessive bending vibrations, which can lead to reduced performance, increased wear and tear, and even structural damage.

The Importance of Vibrating Conveyor Stability

Vibrating conveyors are widely used for their ability to transport materials efficiently, but their stability is paramount. Excessive bending vibrations can undermine their functionality and pose operational challenges.

Causes of Excessive Bending Vibration

- Resonance : Resonance is a common culprit behind excessive bending vibration. When the conveyor’s natural frequency matches the excitation frequency, it can result in significant oscillations. This phenomenon occurs when the excitation force, typically generated by the conveyor’s motor or drive mechanism, is not adequately controlled.

- Uneven Material Distribution : Uneven material distribution along the conveyor can also induce bending vibrations. When the load is not evenly distributed, it creates imbalances that lead to oscillations and potentially harmful bending.

Preventive Measures of Vibrating Conveyor Stability

- Dynamic Analysis : Conducting a dynamic analysis of the vibrating conveyor is essential to identify potential issues before they become problematic. This analysis can help determine the conveyor’s natural frequency and its susceptibility to resonance.

- Proper Material Distribution : Ensuring that materials are evenly distributed along the conveyor is a simple yet effective preventive measure. Proper material handling systems and distribution chutes can help achieve this.

Hazards of bending vibration produced by vibrating conveyor

The generation of bending vibration will cause greater stress inside the conveyor, thereby shortening its working life. What’s more serious is that when there is a large bending vibration, its amplitude and vibration direction angle will change significantly, and the average velocity of the material at different positions in the tank will have a significant difference. Due to the sliding movement in some parts, the moving speed of the material is significantly reduced, and the thickness of the material layer is significantly increased, which accelerates the wear of the tank body.

Therefore, in the process of designing and debugging the vibrating conveyor, it is necessary to avoid this harmful vibration. One of the basic measures is to avoid the natural frequency of each order of bending vibration of the tank close to the working frequency.

Measures to Prevent Bending Vibration of Vibrating Conveyor

In order to prevent excessive bending vibration of the vibrating conveyor, the following specific measures should be taken.

- The vibration mass of the upper and lower tubes of the double-tube vibrating conveyor should be close to equal in several sections divided along the length of the entire conveyor. The vibrating mass of the trough body and the bottom frame of the single-tube dual-mass vibrating conveyor should be distributed in the same proportion in several sections divided along the length of the conveyor.

- The amount of material in the upper and lower tubes of the double-tube vibrating conveyor should be close to equal and should be evenly distributed, and the single-tube vibrating conveyor should also be evenly distributed. In order to reduce the influence of material distribution inhomogeneity on the elastic bending vibration of the trough, it is an effective method to appropriately increase the throwing index to reduce the amount of material in the trough.

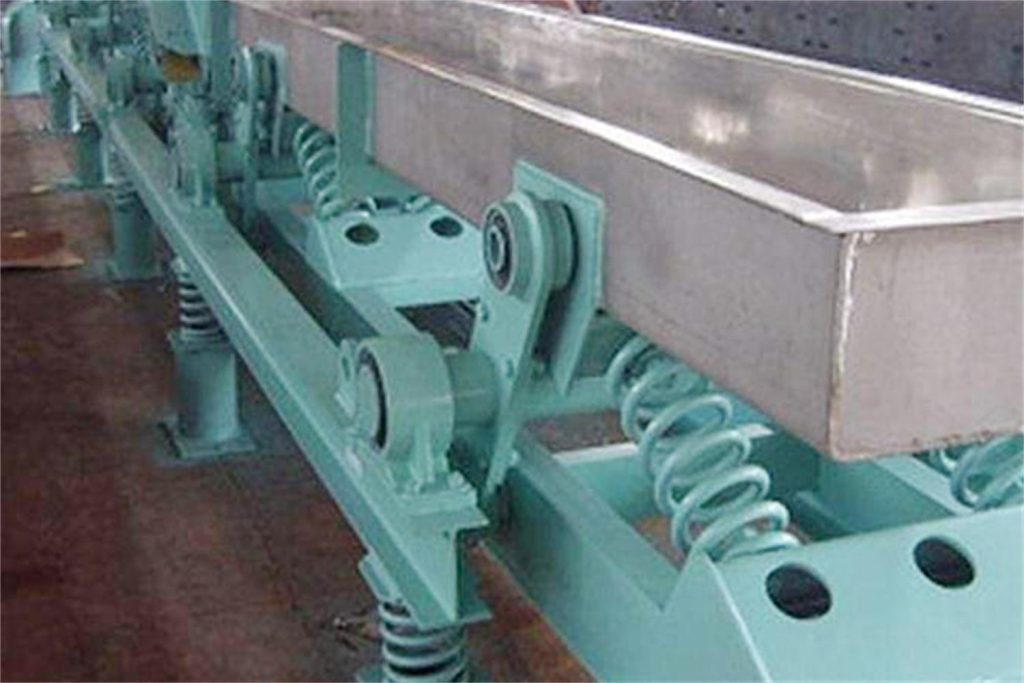

- Accessories such as guide rods and main vibration springs should be evenly distributed along the entire length of the tank, and vibration isolation springs should also be evenly distributed.

- The unbalanced rotating mass of the transmission part should be balanced, and a balance weight is usually added to the pulley.

If it is found that the vibrating conveyor has a large bending vibration, a counterweight can be added to the appropriate position of the tank body, which can reduce the bending vibration to a certain extent.

Conclusion

In conclusion, excessive bending vibration in vibrating conveyors system can be a challenging problem, but it is not insurmountable. By understanding the causes, conducting dynamic analyses, and implementing preventive measures such as damping systems, proper material distribution, and advanced control algorithms, it is possible to maintain the stability and efficiency of vibrating conveyors in various industrial applications. The case study highlights the practical application of these strategies, demonstrating how they can be effectively employed to prevent and mitigate excessive bending vibration issues, ensuring smooth and reliable material handling processes.