Vibrating conveyors have gained popularity in various industries due to their ability to efficiently transport bulk materials. However, like any other technology, they do come with their fair share of disadvantages. In this article, we will explore the drawbacks of vibrating conveyors and provide insights into potential challenges faced by organizations utilizing this technology.

5 Important Things to Know Before Starting a Vibratory Conveyor

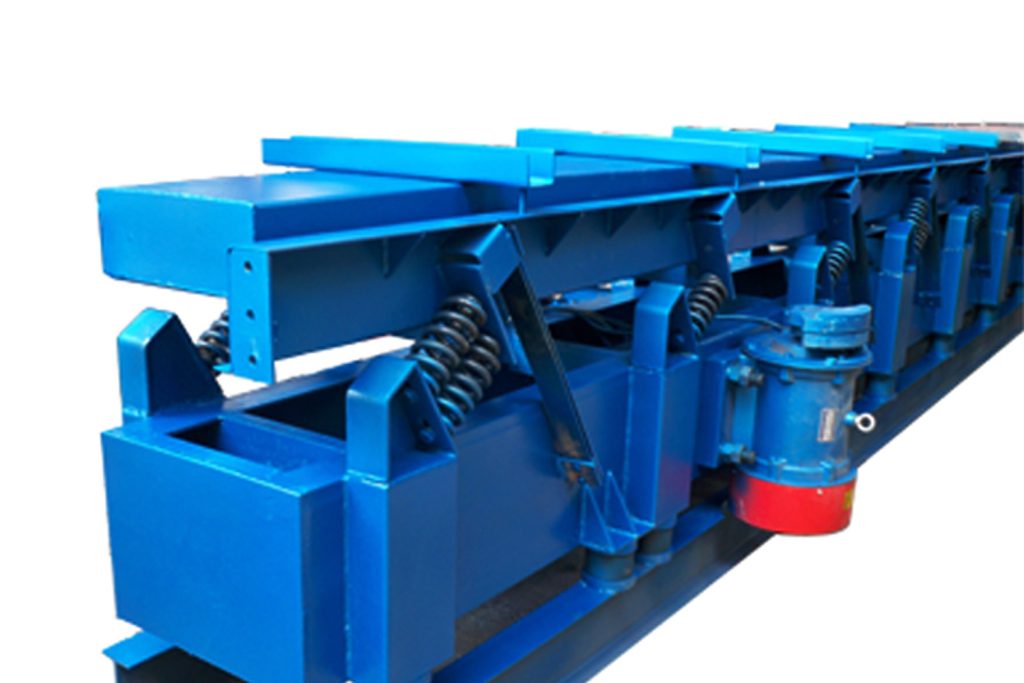

Vibrating conveyors use vibrations to transfer materials from one point to another. They are commonly used in industries such as mining, food processing, pharmaceuticals, and many others.

- Noise and Vibration: Vibrating conveyors generate substantial noise and vibration levels during operation. This can be a concern in noise-sensitive environments or industries that require strict noise regulations. Adequate noise and vibration control measures must be implemented to ensure a comfortable and safe working environment.

- Equipment Maintenance : Vibrating conveyors consist of several moving parts, such as motors, bearings, and belts. These components require regular maintenance to prevent wear and tear, ensuring smooth operation. Failure to schedule proper maintenance can lead to costly downtime and decreased productivity.

- Limited Material Types: Vibrating conveyors are not universally suitable for all material types. Some materials, such as fine powders or substances with sticky properties, might experience issues during transit. The vibratory motion can cause fine particles to become airborne or form clumps, leading to difficulties in material handling or potential product loss.

- Limited Distance and Capacity: Vibrating conveyors are suitable for relatively short distances and lower capacity applications. For longer distances or higher throughput requirements, other types of conveyors such as chain conveyors or belt conveyors may be more suitable. It is essential to assess the specific needs of your operations before opting for a vibrating conveyor system.

- Energy Consumption: Vibrating conveyors typically consume more energy than other conveyor systems due to the nature of their operation. The vibrations require continuous power, contributing to higher energy costs. Implementing energy-efficient measures or exploring alternative conveyor options could help mitigate this disadvantage.

Conclusion

Vibrating conveyors offer advantages but also have notable drawbacks that organizations must carefully consider before implementation. Noise and vibration control, regular maintenance, limited material compatibilities, capacity constraints, and higher energy consumption are among the key disadvantages to address. By evaluating these factors, businesses can make informed decisions about the suitability of vibrating conveyors for their specific applications and needs.