Scraper conveyor is a continuous conveying machine with flexible traction components, which can be used to convey bulk materials such as dust, small particles and small blocks in horizontal, inclined and vertical directions, and is widely used in material conveying in various industrial fields .

The scraper conveyor relies on the internal friction and side pressure of the material. During the process of conveying the material, the pressure in the direction of the scraper chain movement and the pushing force of the lower material on the upper material during continuous feeding. The combination is enough to overcome the external friction resistance and the weight of the material itself generated between the material and the shell when it is conveyed in the machine tank. The material can form a continuous material flow and move forward no matter it is conveyed horizontally, inclined or vertically.

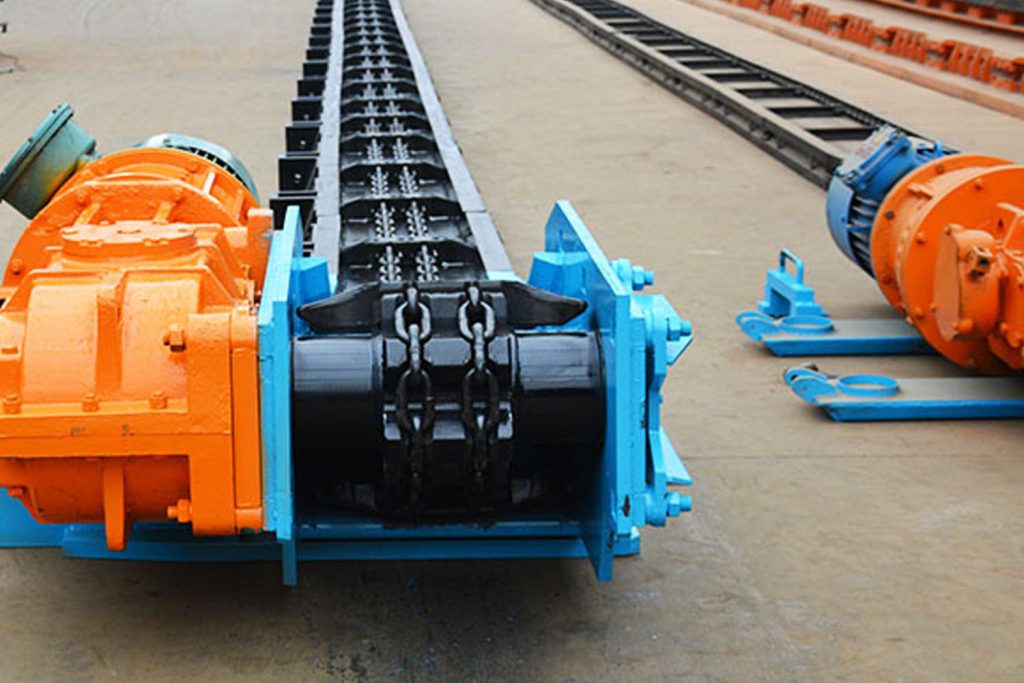

5 installation steps of scraper conveyor

- Install the machine slot according to the requirements of the general assembly drawing and the connection marks of each section of the machine slot when leaving the factory.

- Measure and adjust the total non-straightness of the machine tank and the installation position of flange joints and head and tail wheels.

- Install the scraper chain. Before installing the scraper chain, the specific installation method should be determined according to the model, length and site conditions of the conveyor. Under normal circumstances, the method of segmented assembly is adopted, that is, every 10 sections are strung together into a group, and they are installed in the conveyor group by group. After bypassing the head wheel, it can be driven by manual turning; MC type and MZ type scraper conveyor The scraper chain should be hoisted from top to bottom, but attention should be paid to fixing the tail of the scraper chain to prevent the scraper chain from slipping and causing accidents. For the connection of the scraper chain, the MS type can be connected at the upper part of the horizontal middle section, that is, the unloaded section, and the MC type and MZ type should be connected at the upper observation window of the transition section.

- After the scraper chain is installed, adjust the tensioning device to ensure that the scraper chain has an appropriate tension and ensure that the unused tensioning stroke is not less than half of the total stroke.

- Install the driving device so that it is firmly installed on the foundation or platform support.

Basic requirements for scraper conveyor installation

- The level and verticality of the machine tank should be guaranteed, especially the straightness of the inner wall of the machine tank should be ensured, and no up-down, left-right misalignment at the interface between the flange joint and the guide rail is allowed.

- The head of the conveyor must be firmly welded to the mounting bracket, and the tail and middle section should be properly fixed.

- The head wheel, tail wheel and guide wheel must be centered, and the wheel axles should be kept parallel.

Conclusion

The scraper conveyor is an efficient, reliable and durable material conveying equipment. When installing the equipment, it must be operated in strict accordance with the process standards to ensure that the installation of the equipment can be completed safely and efficiently.