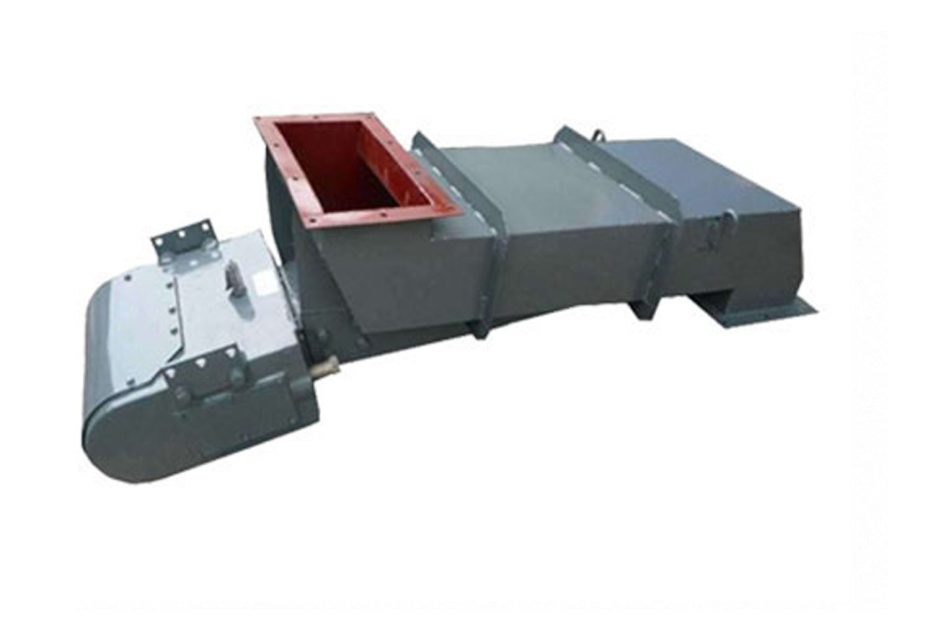

The electromagnetic vibrating feeder is used to uniformly or quantitatively supply block, granular or powdery materials from storage silos or other storage equipment to the receiving equipment. It is an essential equipment for the automation of flow operations.

The electromagnetic vibrating feeder has a simple structure, small size, easy installation and operation, no rotating parts, no need for lubrication, easy maintenance, and low power consumption. The ore feeding amount can be adjusted evenly. This equipment is widely used in mining, metallurgy, coal, electric power, chemical industry, food, glass, refractory materials and other industries.

At the heart of an Electromagnetic Vibratory Feeder lies a sophisticated mechanism that combines electromagnetism and vibration. The system comprises a coil and a magnet arrangement. When an alternating current flows through the coil, it generates a magnetic field that interacts with the magnet, causing it to move back and forth. This reciprocating motion imparts vibrations to the feeder tray, effectively conveying materials forward.

Advantages of Electromagnetic Vibratory Feeders

1. Precision and Control

One of the primary advantages of EVFs is their unparalleled precision and control over material flow. Traditional conveyors may struggle with maintaining consistent rates, especially with fine or irregularly shaped materials. Electromagnetic Vibratory Feeders, on the other hand, allow for precise adjustment of vibration intensity, ensuring a steady and uniform feed. This precision is crucial in processes where accurate dosing or batching is essential.

2. Reduced Wear and Maintenance

Unlike mechanical conveyors that involve direct contact and friction between moving parts, Electromagnetic Vibratory Feeders operate without physical contact. This results in minimal wear and tear, translating to lower maintenance requirements. The absence of wear-inducing components enhances the longevity of the equipment, making it a cost-effective solution in the long run.

3. Quiet Operation

In environments where noise is a concern, EVFs present a notable advantage. The electromagnetic drive mechanism operates with minimal noise, contributing to a quieter working environment. This characteristic is particularly advantageous in settings such as laboratories, where precision and a low noise profile are critical.

4.Versatility in Material Handling

The versatility of Electromagnetic Vibratory Feeders in handling various materials is a key highlight. Whether it’s fine powders, granules, or even fragile components, EVFs excel in delivering a consistent and controlled flow. This adaptability makes them suitable for a wide range of industries, from pharmaceuticals and food processing to mining and construction.

Top 4 Applications of Electromagnetic Vibratory Feeders

| Industry | Application |

|---|---|

| Pharmaceutical | Precise dosing of powders for capsule filling |

| Food Processing | Controlled feeding of ingredients in production lines |

| Mining | Efficient transport of granular materials |

| Construction | Handling and conveying of aggregates |

Conclusion

In conclusion, the integration of Electromagnetic Vibratory Feeders has revolutionized material handling across industries. From their precise control over material flow to the reduction in maintenance needs, EVFs stand as a testament to innovation in the field. As industries continue to seek efficient and reliable solutions for material handling, Electromagnetic Vibratory Feeders emerge as a cornerstone in the pursuit of enhanced productivity and operational excellence.