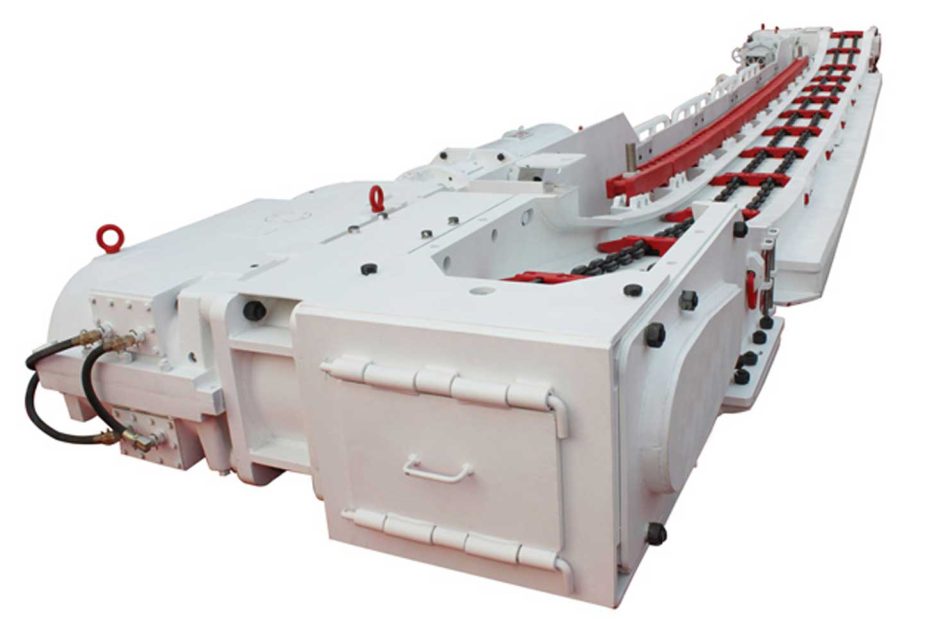

The scraper conveyor is a continuous conveying machine with flexible traction members, which can be used to convey bulk materials in horizontal, inclined and vertical directions.

When the scraper conveyor is working, no matter it is conveyed horizontally or vertically, when the material enters the closed machine groove from the feed port, under the action of external forces such as the thrust of the scraper and the gravity of the material itself, the bulk material forms sufficient internal friction , the internal friction force is enough to overcome the external friction force of the machine groove and the gravity of the material when the material is conveyed vertically, so that the material can form a relatively stable whole, and it will completely flow to the conveyor belt under the action of the scraper chain front delivery.

Causes and solutions for scraper chain deviation or floating chain

Reasons and solutions for the deviation of the scraper chain

- It may be that the verticality of the installation does not meet the requirements, or it may be that the head wheel, tail wheel, guide wheel, and supporting wheel are not aligned, or the axles are not parallel. At this time, it should be adjusted according to the requirements, and make it Meet the requirements.

- It may also be caused by inconsistent tension at both ends of the tail wheel. At this time, the tension device should be adjusted so that the tension at both ends of the tail wheel is consistent and the wheel shaft is perpendicular to the longitudinal centerline of the fuselage.

Reasons and solutions for the floating chain of the scraper chain

- It may be caused by conveying high-moisture and viscous materials. At this time, the scraper should be installed obliquely on the chain or in the carrying trough, and a pressure plate should be arranged every 2m to overcome it.

- It may also be caused by the deformation of the scraper, and the deformed scraper conveyor should be replaced at this time.

- It may also be the reason that the conveying speed is too high. At this time, the conveying speed should be adjusted.

In summary

Scraper conveyor system is a kind of efficient, reliable and durable material conveying equipment. If there are problems such as deviation, broken chain, floating chain, blockage and increased resistance during operation, it should be stopped in time and after passing the maintenance and inspection , to restart production.