In the realm of material handling, achieving efficiency and precision is paramount. The integration of advanced technologies has paved the way for significant advancements, and one such innovation that has revolutionized material handling is the Electromagnetic Vibratory Feeder.

The electromagnetic vibrating feeder is used to uniformly or quantitatively supply materials from the storage bin or other storage equipment to the receiving equipment. It is an essential equipment for the automation of flow operations.Electromagnetic vibrating feeder is mainly used for quantitative or continuous supply of block, granular or powdery materials.

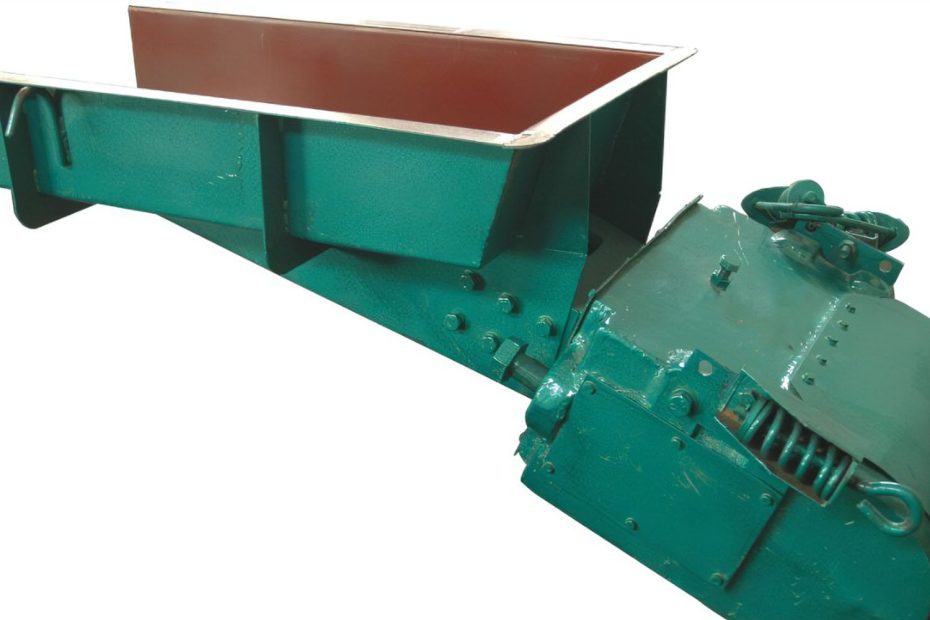

At the heart of an Electromagnetic Vibratory Feeder lies a sophisticated mechanism that combines electromagnetism and vibration. The feeder consists of a tray or trough suspended on springs, and an electromagnetic drive unit underneath. As the electromagnet is energized, it generates a pulsating magnetic field, causing the tray to vibrate. This vibration imparts motion to the material on the tray, facilitating a controlled flow.

Top 3 Advantages Of Electromagnetic Vibratory Feeders

1. Adjustable Vibration Levels

Electromagnetic Vibratory Feeders offer the flexibility of adjusting vibration levels, allowing operators to tailor the feed rate to specific requirements. This adaptability is invaluable in processes where varying material flow rates are necessary, providing a dynamic solution for diverse material handling challenges.

2. Gentle Material Handling

Unlike some traditional conveying systems that may subject materials to harsh forces, Electromagnetic Vibratory Feeders operate with a gentle touch. The controlled vibrations minimize the risk of material degradation or breakage, making them ideal for handling fragile or delicate substances in industries like ceramics and glass manufacturing.

3. Low Power Consumption

Efficiency is a driving force in modern industrial practices, and Electromagnetic Vibratory Feeders align with this ethos by exhibiting low power consumption. The electromagnetic drive system consumes power only during the pulsating cycle, contributing to energy savings and reducing operational costs over the long term.

4. Precision in Material Handling

One of the key advantages of Electromagnetic Vibratory Feeders is their ability to handle materials with unparalleled precision. The controlled vibrations allow for the smooth and regulated movement of a wide range of materials, from fine powders to larger particles. This precision is particularly crucial in industries such as pharmaceuticals and food processing, where accurate dosing and gentle handling are imperative.

Top 2 Real-World Applications Of Electromagnetic Vibratory Feeders

- Pharmaceutical Industry : In pharmaceutical manufacturing, where precision is non-negotiable, Electromagnetic Vibratory Feeders find application in the controlled feeding of ingredients into various processes. From precisely dosing active pharmaceutical ingredients to ensuring a consistent flow of excipients, these feeders contribute to the production of pharmaceuticals with the highest quality standards.

- Mining and Aggregates : In the mining and aggregates sector, where materials of varying sizes and densities need to be efficiently transported, Electromagnetic Vibratory Feeders play a pivotal role. Their ability to handle diverse materials, from fine ores to coarse aggregates, ensures a continuous and controlled material flow in processes like crushing and screening.

A Comparative Insight: Electromagnetic Vibratory Feeders vs. Alternatives

To appreciate the advantages of Electromagnetic Vibratory Feeders, it’s essential to compare them with alternative material handling systems. The following table provides a succinct comparison:

| Material Handling System | Advantages | Disadvantages |

|---|---|---|

| Electromagnetic Vibratory Feeders | Adjustable vibration, gentle handling, low power | Initial cost may be higher than some alternatives |

| Belt Conveyors | Suitable for long distances, high capacity | Limited precision, maintenance-intensive |

| Pneumatic Conveyors | Versatile, suitable for various materials | Energy-intensive, potential material degradation |

Conclusion

As industries embrace automation, Electromagnetic Vibratory Feeders have evolved to seamlessly integrate with automated systems. This integration enhances overall efficiency by allowing precise control through programmable logic controllers (PLCs) and sensor feedback systems, enabling real-time adjustments to accommodate changing production needs.

In conclusion, Electromagnetic Vibratory Feeders stand as a testament to the marriage of precision and efficiency in material handling. Their ability to delicately handle a wide range of materials, coupled with adjustable vibration levels and low power consumption, positions them as indispensable assets in various industries. As technology continues to advance, the continued innovation in Electromagnetic Vibratory Feeders promises even greater strides in enhancing material handling processes, further solidifying their role in the ever-evolving landscape of industrial automation.