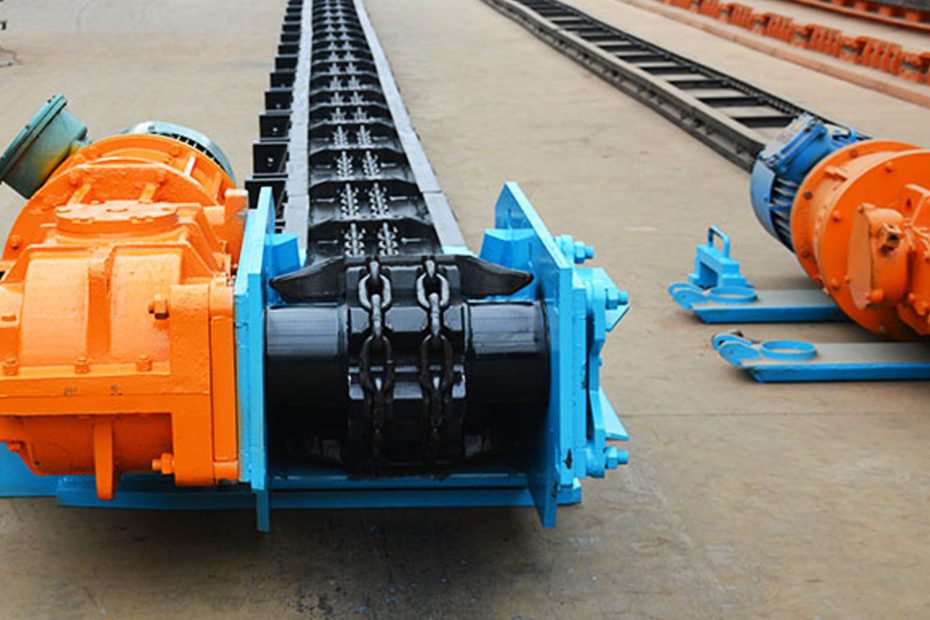

Scraper conveyor is a continuous conveying machine with flexible traction components, which can be used to convey bulk materials such as dust, small particles and small blocks in horizontal, inclined and vertical directions, and is widely used in material conveying in various industrial fields .

Scraper conveyor is a commonly used conveying equipment that can convey bulk materials from one place to another. The scraper conveyor can convey materials in a sealed manner, with high work efficiency, energy saving and environmental protection, and is often used in coal mines, metallurgy, building materials, chemical industries and other industries.

As a common material conveying equipment, the scraper conveyor has many advantages and disadvantages, which will be explained in detail below.

Advantages of scraper conveyor

- Wide applicability: The scraper conveyor has a wide range of applications. It is not only suitable for normal temperature environments, but also can operate normally in high temperature, low temperature, humid and other working environments, and is suitable for the transportation of various materials.

- High conveying efficiency: The conveying efficiency of the scraper conveyor is high, the main reason is that its conveying speed is fast, the material conveying is stable, and the problems such as blockage are not easy to occur, which can greatly improve the efficiency of logistics conveying.

- High reliability: When the scraper conveyor is transporting materials, its key components such as scrapers and chains are durable, not easy to be damaged, and have high reliability and stability.

- Long transmission distance: The scraper conveyor can carry out horizontal conveying, inclined conveying and lifting conveying according to different process requirements, and its conveying distance can be as far as hundreds of meters, which can meet the material conveying needs of different occasions.

- Environmental protection and energy saving: The sliding transportation method adopted by the scraper conveyor has low friction, low energy consumption, and no environmental pollution such as noise, and has relatively good environmental protection and energy saving effects.

Disadvantages of scraper conveyor

- High maintenance cost: The scraper conveyor has many parts and requires frequent maintenance, including chain lubrication, scraper replacement, etc. The maintenance requirements are relatively high, and a lot of manpower and material resources are required.

- Large floor area: Because the scraper conveyor needs to run multiple devices such as chains, motors, and reducers, it occupies a large area and has certain limiting factors.

- Poor adaptability to materials: Scraper conveyors have great difficulties in conveying fibrous materials, because such materials are easily stuck and trapped, and corresponding measures need to be taken.

- Loud running noise: When the scraper conveyor is running, due to the friction between the chain and the reducer, it will generate a certain degree of noise, which may affect production operations.

The maintenance operation is relatively dangerous: the maintenance operation of the scraper conveyor needs to be close to the running machinery, which has certain requirements for the safety of the operator, and relevant protective measures need to be paid attention to.

Conclusion

The above are some advantages and disadvantages of scraper conveyors system. Users need to consider comprehensively according to their own actual conditions when choosing to use them, and take corresponding measures.