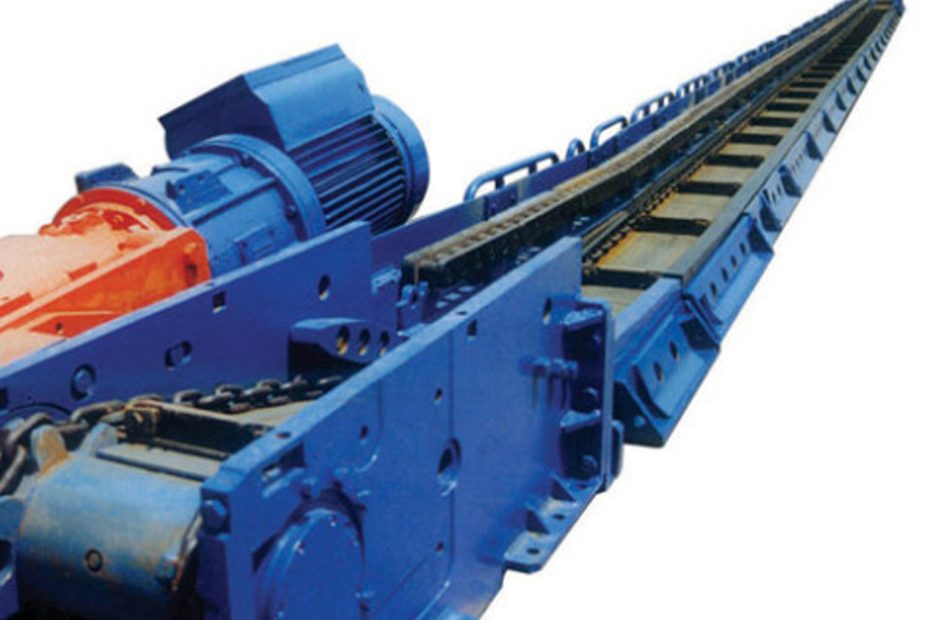

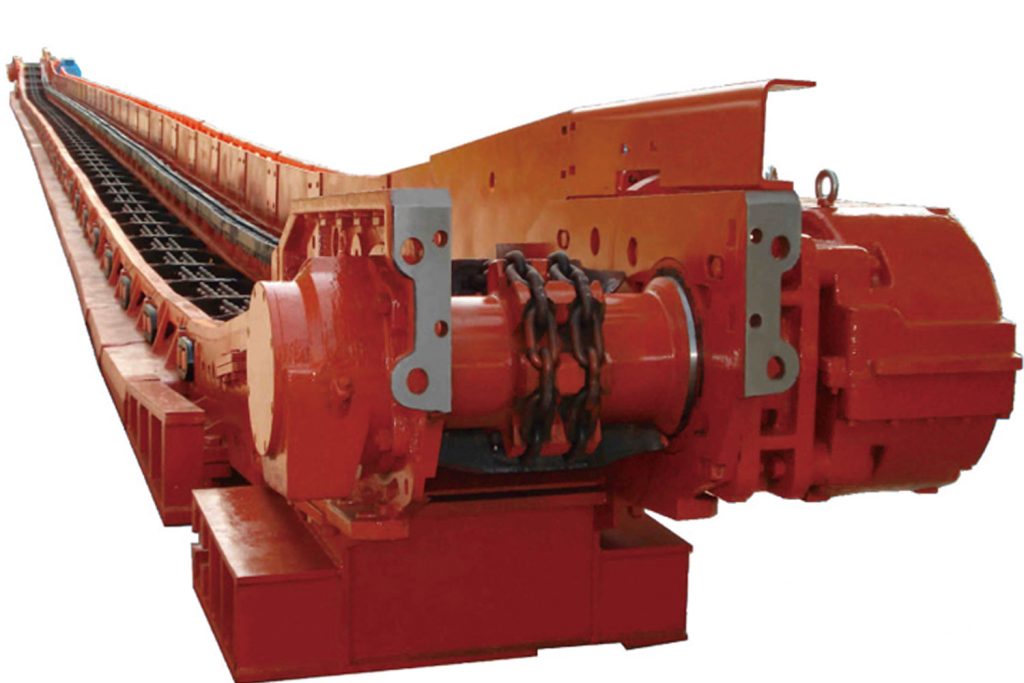

Buried scraper conveyor is a common material conveyor system, which is a continuous transportation equipment that uses the moving scraper chain to continuously transport bulk materials within a closed rectangular section or circular tube-shaped shell.

It is called “buried scraper conveyor” because the scraper chain is buried in the material and moves forward with the material during operation.

When the buried scraper conveyor is working, the material enters the load-bearing section of the casing through the feed port, and is pushed by the scraper, and moves forward together with the scraper strip to form a whole. The unloaded section of the machine is returned.

The buried scraper conveyor can convey powdery, granular and small block materials in horizontal, inclined or vertical directions, and is widely used in grain, light industry, chemical industry and other industries.

Explain the 5 advantages and disadvantages of buried scraper conveyor

Advantages of buried scraper conveyor

- Advantage 1#: wide application range, many kinds of materials to be conveyed, many materials that are difficult to be conveyed by other continuous conveying machinery can be conveyed by buried scraper conveyor;

- Advantage 2#: good airtight performance, the material is transported in the closed machine tank, no spilling, no leakage, dustproof, waterproof, anti-virus, anti-explosion, improved working conditions, and prevented environmental pollution;

- Advantage 3#: The process layout is more flexible, it can be used for material transportation in different directions, and it is easy to realize multi-point feeding or multi-point unloading;

- Advantage 4#: small size, small footprint, can be used in relatively narrow working places;

- Advantage 5#: There is basically no relative movement between the material and the scraper chain during transportation, so the damage to the material is small; easy to install, easy to operate and maintain, and safe and reliable to operate.

Disadvantages of buried scraper conveyor

- Disadvantage 1#: There are certain restrictions on conveying distance and lifting height;

- Disadvantage 2#: The wear of the scraper chain and the machine trough is relatively large, and the wear parts are mainly the joints of the chain, the bottom plate of the machine trough and the guide rails, especially the disadvantage 3#: the wear is more serious when conveying abrasive dusty materials ;

- Disadvantage 4#: Large power consumption; it is not suitable for conveying materials with high viscosity, high suspension, large lumps and abrasiveness.

In summary

Scraper conveyor is an efficient, reliable and durable material conveying equipment. It has the advantages of good airtight performance, high work efficiency, energy saving and environmental protection, but it also has disadvantages such as large power consumption. It is often used in coal mines, metallurgy, Building materials, chemical and other industries.