Scraper conveyor and vibrating conveyor are both conveyor system. used in industrial production lines, but they have different working principles, applicable ranges, and technical characteristics. Here are the differences and characteristics of these two devices in detail.

Five differences between scraper conveyor and vibrating conveyor

Difference in Working Principle

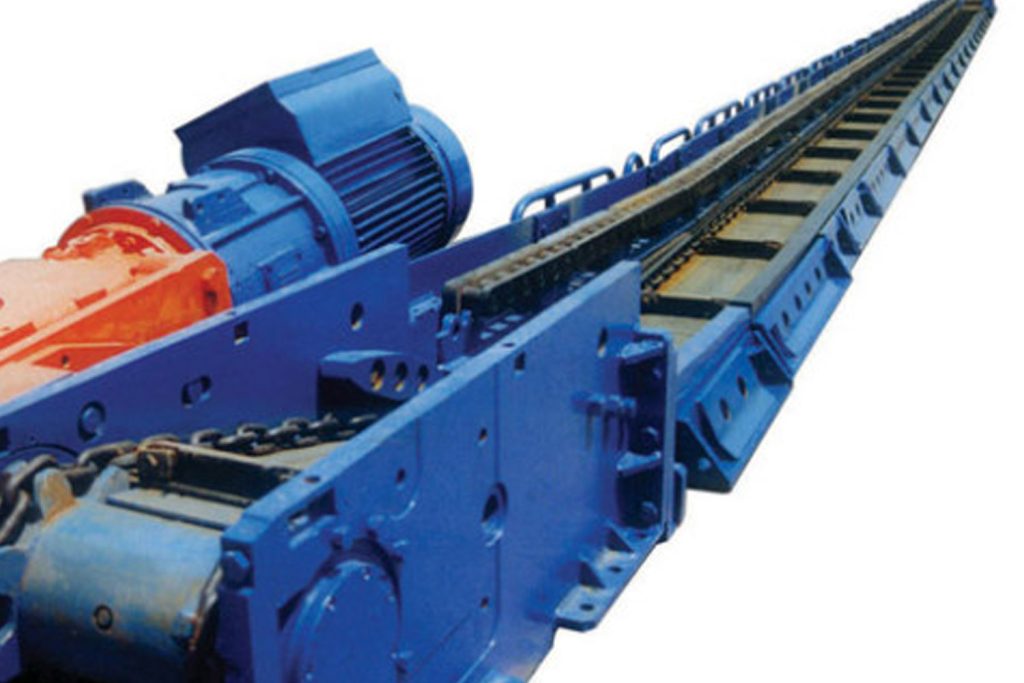

The working principle of scraper conveyor is to fix the scraper firmly on the chain by a chain set and then drive the chain to move the scraper along the conveyor by an electric motor. The scraper pushes the material from the feed port to the discharge port in the process of movement, realizing continuous material conveying. Because the scraper is relatively heavy, the conveying speed is slow, so it is suitable for conveying granular and powdery materials.

Vibrating conveyor, on the other hand, uses a vibrating motor to make the vibrator vibrate, which causes the material to form an expanded and loose state in the conveying pipe. In this state, the material will be constantly pushed forward in the pipeline and reach the output purpose through the vibration of the vibrator. Vibrating conveyor is suitable for conveying granular and powdery materials but not suitable for conveying cohesive materials.

The structural features are different.

Scraper conveyor mainly consists of sprocket, chain, scraper and other components. It is suitable for conveying relatively heavy materials, so its equipment structure is relatively heavy. Vibrating conveyor is mainly composed of a vibrator, support, sound insulation clip, and other components, with a relatively simple and light structure. Scraper conveyor requires longer scraper and chain and requires sealing to prevent dust generation during use.

Vibrating conveyor, on the other hand, has a simple structure and does not require special sealing.

Wear resistance is different

In terms of wear resistance, Scraper conveyor scrapers are made of chrome alloy, with high hardness and long service life.

The components of the vibrating conveyor need to be frequently replaced and have lower wear resistance than the scraper conveyor.

Difference in Applicable Range

Due to the heavy and wear-resistant quality of scraper conveyor scrapers, it is suitable for transporting materials containing large particles. At the same time, scraper conveyor can also be equipped with sealing devices and is suitable for transporting special materials such as corrosive, flammable, and explosive materials. In contrast, when transporting materials by vibrating conveyor, attention should be paid to the size of individual particles of the material. Particles that are too large or too small are not suitable for vibrating conveyor.

Difference in Technical Characteristics

Scraper conveyor has the characteristics of good stability, long conveying distance (up to 300 meters or more), can work with other equipment, and occupies a small space. Compared with vibrating conveyor, scraper conveyor has lower transportation efficiency and higher energy consumption. Vibrating conveyor, on the other hand, has the characteristics of high transportation efficiency, low noise, and low energy consumption. Similarly, the transport distance of vibrating conveyor is relatively short, generally not more than 50 meters.

summary

scraper conveyor is suitable for transporting large particles, large block materials, and special requirements materials. Vibrating conveyor is suitable for conveying granular and powdery materials.

If precise positioning or higher conveying accuracy is required, scraper conveyor should be selected. If high efficiency and low noise are required, vibrating conveyor can be selected.