A vibrating conveyor is a material conveying device that uses vibration force to convey materials from one point to another. It is very common in various fields, including mining, chemical industry, food, building materials, etc.

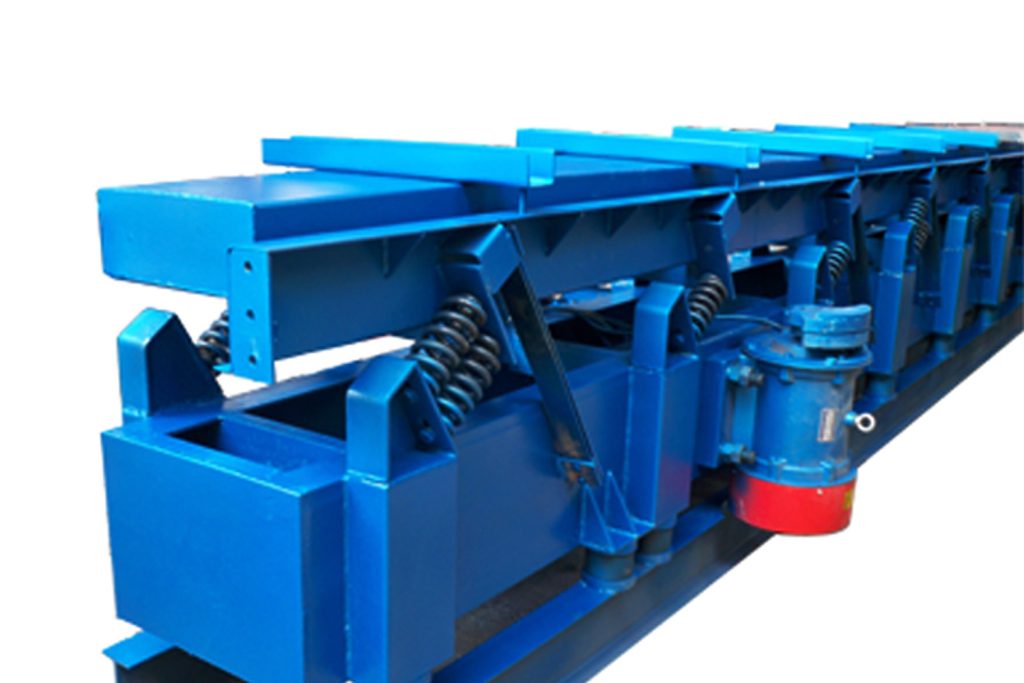

Inertial Vibrating Conveyor is a material conveying device created based on the principle of vibration force and mass inertia, also known as inertial suspension conveyor.

In this device, the material is first screened through the vibrating screen, and the fine material is separated from it. Then, the material will be transported to the vibrating screen, and the material will be transported to the desired position through the inertial vibration of the material.

The inertia vibrating conveyor has a simple structure and low operating costs, and is suitable for conveying various pneumatic conveying and materials that have no rigid requirements in the transportation area, are easy to accumulate, and are easy to wear.

Introduce 4 characteristics of inertial vibrating conveyor

High efficiency and energy saving: The inertial vibrating conveyor adopts the principle of inertial trajectory vibration transmission, with low operating cost and high conveying efficiency.

Good stability: In the material transmission process of the inertial vibrating conveyor, the principle of inertial transmission is adopted, and the material will not have an oblique side flow during the transmission process, so the transportation stability is better.

Easy to maintain: The inertia vibrating conveyor adopts high-quality transmission device, which is small in size, light in weight, stable in operation and has a long service life.

Wide range of application: The inertial vibrating conveyor has a wide range of materials, and can transport various granules, powders, and bulk materials, and has a very wide range of applications.

Summary

Inertial vibrating conveyor is a kind of equipment that transports materials through the principle of vibration force and mass inertia. It has the characteristics of high efficiency, energy saving, stability and easy maintenance. It is widely used in building materials, metallurgy, chemical industry, food and other industries.