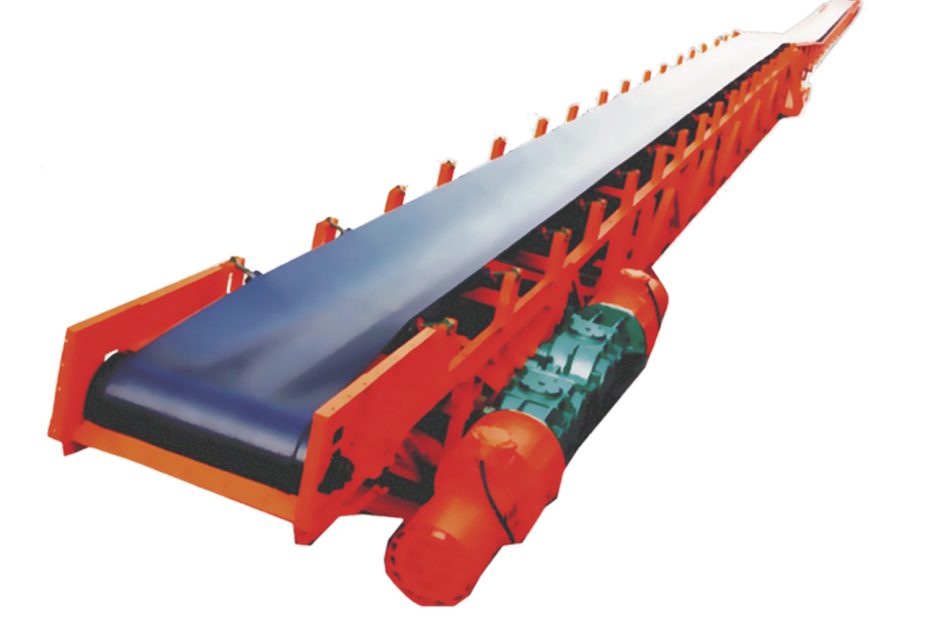

Belt conveyor is a continuous conveying equipment that uses flexible tape as material carrying part and traction part. According to the principle of friction, the transmission roller drives the belt to transport the material to the required place. The belt winds around the driving roller at the head and the redirecting roller at the tail, forming a stepless link belt.

Two selection methods for belt conveyors

Belt conveyor is an important material conveying equipment, which is widely used in mining, building materials, metallurgy, chemical industry and other industries.How to choose a suitable belt conveyor is a problem that must be considered before production.

Selection according to the characteristics of the conveyed material

The selection of the belt conveyor should be considered comprehensively based on the material type, particle size, and properties of the conveyed material. For example, the belt conveyor for conveying bulk materials should adopt the lower plate type, while the belt conveyor for conveying composite and bulk materials needs to consider factors such as conveying height, curve, and slope angle.

Selection according to conveying distance and conveying volume

The selection of the belt conveyor should also consider the conveying distance and conveying capacity of the belt conveyor. Normally, the type selection is determined according to the material flow rate and the conveying distance, and a belt conveyor with a larger volume and a higher conveying speed is selected. The type selection should be calculated according to the conveying speed, material flow and conveying distance of the conveyor to ensure that the appropriate belt conveyor is selected.

Things to note when using belt conveyors

Make a delivery plan

After selecting the belt conveyor, it is necessary to formulate a conveying plan according to the specific situation, and the transmission distance, number of curve segments, height, slope, etc. also need to be determined. In addition, the speed, adjustment method, and process requirements during transmission also need to be set in detail. Making a suitable conveying plan is an important step in the selection of belt conveyors. Every detail of conveying should be considered to avoid problems.

consider accessories

The accessories of the belt conveyor are also one of the factors that need to be considered when selecting. Such as bearings, gears, transmissions, electrical components, etc., these accessories play a key role in the normal operation and long life of the belt conveyor. Therefore, when choosing a belt conveyor, it is necessary to focus on the quality and reliability of the accessories to avoid affecting the safety and stability of the belt conveyor.

Focus on technical details

When choosing a belt conveyor, you need to pay attention to some technical details. For example, it is necessary to pay attention to whether its design and manufacturing standards are suitable, and whether the equipment meets the industry standards; in addition, the selection of belt conveyors should be considered comprehensively in terms of durability and performance.

Conclusion

In the selection method of the belt Conveyor Systems , it is necessary to select the type according to the characteristics of the conveyed material, conveying distance, and conveying volume. On this basis, formulate a suitable conveying plan and pay attention to the quality and technical details of accessories to achieve the purpose of belt conveyor selection. In addition, it is necessary to choose a reliable manufacturer and provide after-sales service to ensure that the equipment can work stably and efficiently in the next production process.