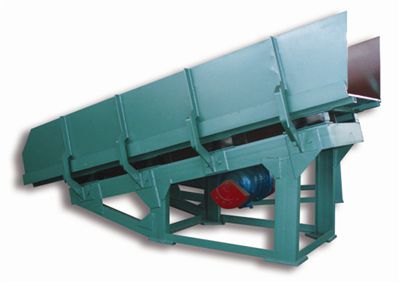

Automation has become the backbone of modern industrial processes, enhancing efficiency and precision. Among the myriad technologies contributing to automation, Electromagnetic Vibratory Feeders stand out as indispensable devices.

Electromagnetic Vibratory Feeders : Working Principles

Electromagnetic Vibratory Feeders operate on the principle of electromagnetic vibrations to convey and discharge materials. A coil is energized with an alternating electric current, creating a magnetic field. This magnetic field interacts with an armature, causing it to vibrate. These vibrations are then transmitted to the material, propelling it forward in a controlled manner.

Key Components

- Coil and Armature: The coil and armature constitute the core components. The alternating current in the coil generates the magnetic field, while the armature converts this magnetic energy into mechanical vibrations.

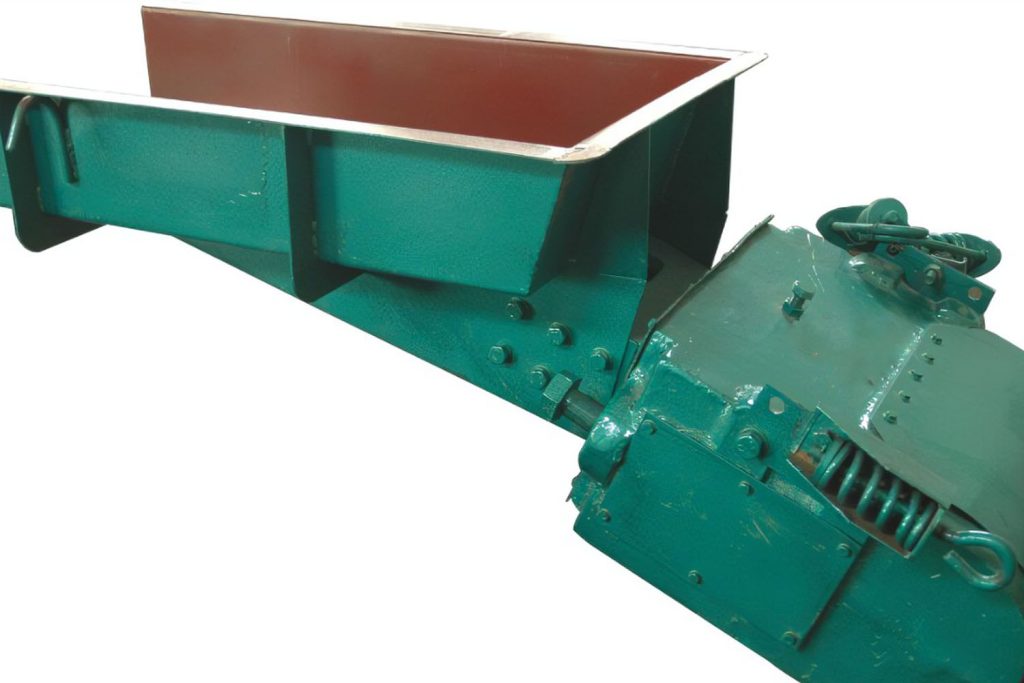

- Pan or Trough: The pan or trough serves as the conveying surface, ho lding and guiding the materials. Its design ensures optimal material flow and prevents spillage.

- Controller: An essential component, the controller regulates the frequency and amplitude of vibrations, allowing precise control over the feeding process.

Top 3 Applications in Automation of Electromagnetic Vibratory Feeders

1. Assembly Lines

In automated assembly lines, precise and controlled feeding of components is paramount. Electromagnetic Vibratory Feeders play a pivotal role in ensuring a steady supply of parts, facilitating seamless assembly processes. Their ability to handle a wide range of components makes them versatile solutions for diverse assembly line requirements.

2. Packaging Systems

Efficiency is at the heart of automated packaging systems. Electromagnetic Vibratory Feeders contribute to this efficiency by ensuring a consistent and regulated flow of packaging materials. From filling machines to labeling systems, these feeders streamline the packaging process.

3. Pharmaceutical Production

In the pharmaceutical industry, precision and hygiene are critical. Electromagnetic Vibratory Feeders, with their gentle material handling and customizable design, find application in pharmaceutical production lines, precisely dispensing ingredients for drug formulation.

Top 3 Advantages of Electromagnetic Vibratory Feeders in Automation

- Precision and Control :One of the standout features of Electromagnetic Vibratory Feeders is their ability to provide precise control over the feeding process. The adjustable frequency and amplitude ensure that materials are conveyed with accuracy, making them ideal for applications demanding strict adherence to dosage and timing.

- Gentle Material Handling :The gentle vibratory motion of these feeders is particularly beneficial for fragile or delicate materials. In industries such as pharmaceuticals or electronics, where careful handling is crucial, Electromagnetic Vibratory Feeders excel in ensuring damage-free transportation of materials.

- Customizable Design :Versatility is a hallmark of Electromagnetic Vibratory Feeders. Their customizable design allows for adaptation to various materials, sizes, and shapes. This flexibility is a boon in automation setups where different types of materials need to be fed into the production line.

| Advantages | Electromagnetic Vibratory Feeders | Traditional Feeding Systems |

|---|---|---|

| Precision and Control | High | Moderate |

| Gentle Material Handling | Yes | No |

| Customizable Design | Yes | Limited |

Integration Challenges and Solutions

While Electromagnetic Vibratory Feeders offer numerous advantages, their integration into automated systems may pose challenges. Common issues include material spillage and variations in material characteristics. However, innovative solutions, such as advanced control algorithms and pan designs, address these challenges, ensuring smooth integration into diverse automation setups.

Future Trends and Innovations

As automation continues to evolve, the future of Electromagnetic Vibratory Feeders holds exciting possibilities. Advancements in sensor technologies, artificial intelligence, and connectivity are likely to enhance the efficiency and adaptability of these feeders, making them even more integral to the automated landscape.

Conclusion

In conclusion, Electromagnetic Vibratory Feeders play a pivotal role in the realm of automation, offering precision, versatility, and gentle material handling. Their application in assembly lines, packaging systems, and pharmaceutical production showcases their adaptability across diverse industries. As technology advances, these feeders are poised to evolve, contributing to the ongoing transformation of automated processes worldwide.