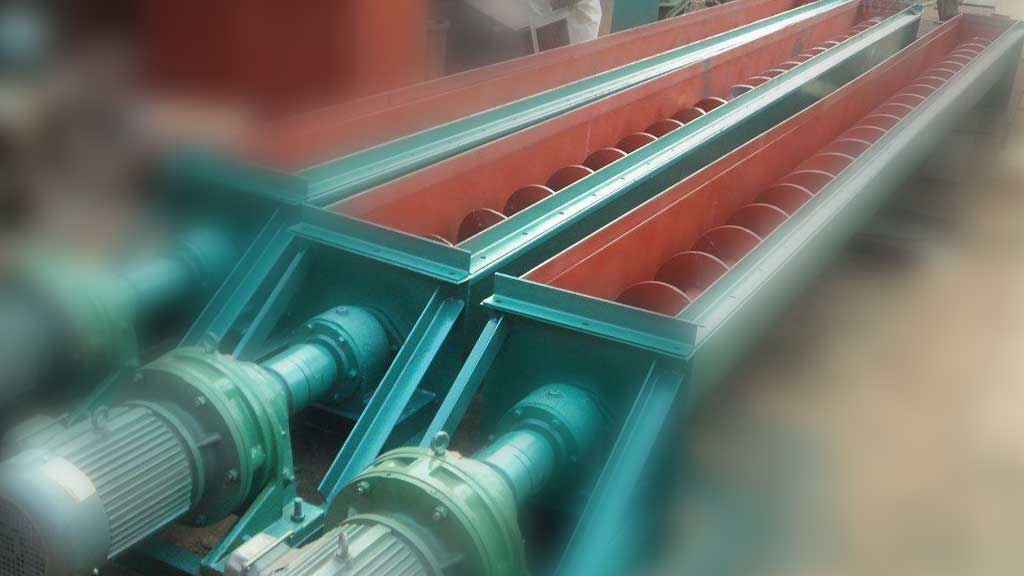

Automated Flexible Conveyor introduces an innovative solution to improve worker safety and maintenance efficiency – the Spiralfeeder push unit solid screw conveyor. This new conveyor design sets the drive mechanism at floor level near the hopper, allowing easy access to the electric motor and gearbox without the need for ladders or lifting devices.

The Spiralfeeder push unit is ideal for companies in industries such as food, nutrition, chemical, and pharmaceuticals, where low ceiling facilities and space constraints are common. With its floor level drive mechanism and gentle pushing effect, this conveyor enables smooth, efficient, and ergonomic material transfer of powders, pellets, and other dry, bulk materials.

Spiralfeeder Push Unit: An Overview

The Spiralfeeder push unit solid screw conveyor is designed to streamline maintenance operations and enhance worker safety. Unlike traditional screw conveyors with the drive mechanism located at the discharge end, this innovative conveyor places the drive mechanism at floor level near the hopper. This configuration enables easy access to the electric motor and gearbox, eliminating the need for ladders, mezzanines, or lifting devices during maintenance.

The floor level drive mechanism in the Spiralfeeder push unit creates a gentle pushing effect on the material, as opposed to the pulling effect used in conventional screw conveyors. This gentle pushing action ensures a smooth and efficient transfer of powders, pellets, and other dry, bulk materials inside an enclosed tube. The highly ergonomic and mobile design of the conveyor makes it a practical solution for companies with low ceiling facilities or constrained spaces.

Top 4 Advantages of the Spiralfeeder Push Unit

The introduction of the Spiralfeeder push unit solid screw conveyor offers numerous advantages for material handling operations:

- Enhanced Maintenance Accessibility: Placing the drive mechanism at floor level near the hopper allows maintenance personnel to access the electric motor and gearbox with ease. This streamlines maintenance procedures, saving time and effort while promoting worker safety.

- Space Optimization: The floor level drive mechanism eliminates the need for additional space-consuming structures, such as ladders or mezzanines, making it ideal for facilities with low ceilings or limited space availability.

- Gentle Material Transfer: The gentle pushing effect of the Spiralfeeder push unit ensures a smooth and efficient material transfer, minimizing the risk of product degradation or spillage during transportation.

- Mobile Configuration: The conveyor’s mobile design adds to its versatility, allowing it to be easily moved and repositioned as needed within the facility.

Top 4 Applications of the Spiralfeeder Push Unit

The Spiralfeeder push unit solid screw conveyor finds applications across various industries, particularly in situations where low ceiling facilities and efficient maintenance procedures are critical. Some key application areas include:

- Food Industry: In food processing plants, where hygiene and safety are paramount, the conveyor’s floor level drive mechanism enhances maintenance accessibility while promoting a clean working environment.

- Pharmaceutical Industry: The pharmaceutical sector, with its stringent safety and regulatory requirements, benefits from the conveyor’s efficient material transfer and easy maintenance features.

- Chemical Manufacturing: In chemical plants, where space optimization and safety are crucial, the Spiralfeeder push unit ensures a reliable and ergonomic material handling process.

- Nutrition and Supplements: Companies producing nutrition and supplement products appreciate the conveyor’s gentle material transfer, preserving the integrity of delicate ingredients.

Conclusion

The introduction of the Spiralfeeder push unit solid screw conveyor marks a significant advancement in material handling technology. By placing the drive mechanism at floor level near the hopper, this innovative design enhances maintenance accessibility and promotes worker safety. Industries with low ceiling facilities and space constraints, such as food, pharmaceuticals, chemicals, and nutrition, can benefit from the conveyor’s efficient material transfer and ease of maintenance.

The gentle pushing effect of the Spiralfeeder push unit ensures a smooth and reliable material transfer process, minimizing product degradation and spillage. Its mobile configuration adds to its versatility, allowing for easy repositioning within the facility. As companies seek ways to optimize maintenance procedures and improve material handling efficiency, the Spiralfeeder push unit solid screw conveyor stands as a practical and reliable solution for a wide range of industries.