Vibratory feeders are essential components in various industrial processes, facilitating the controlled transportation of materials. To guarantee their effectiveness and longevity, it’s crucial to adhere to specific installation requirements.

Installation Guide for Vibrating Feeder

Emphasis is placed on all aspects of overall installation, hanging installation, maintaining proper clearances, and electrical grounding. Following these recommendations will ensure efficient and safe operation of your vibratory feeder.

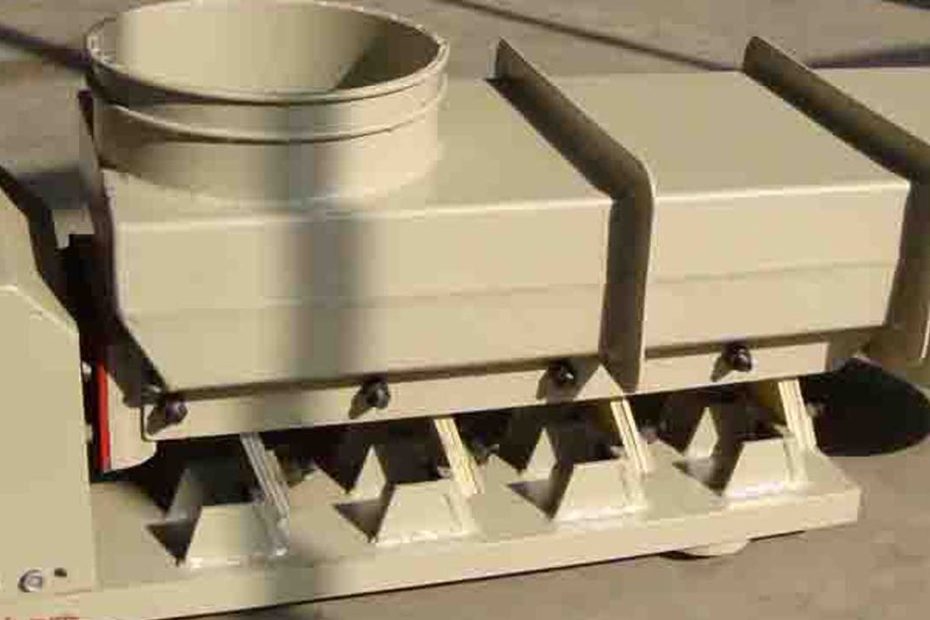

Whole-Unit Installation

In most cases, it’s recommended to install the vibratory feeder as a complete unit at the designated work location. However, if on-site conditions necessitate the separation of the trough and the exciter for installation, it’s imperative to diligently secure the connection bolts between the exciter and the trough.

Suspended Installation

For suspended installations, careful attention must be given to balance the four vibration isolators. Additionally, a thorough check of the trough’s lateral level is necessary. Failure to achieve proper balance and alignment can result in material deviation during the feeding process.

Maintaining Clearances

Vibratory feeders can exhibit certain oscillations during operation, making it essential to maintain a safe distance between the feeder and nearby objects to prevent collisions. The recommended minimum longitudinal clearance is 50 to 100 millimeters, while the minimum lateral clearance is 25 to 50 millimeters.

Preparing for Operation

After installation, it’s crucial to loosen the inspection screws on both sides of the exciter housing for electromagnetic vibratory feeders. Neglecting this step can hinder the intended vibrations of the feeder during operation, affecting its performance.

Electrical Grounding and Protection

The housing of the electromagnetic vibratory feeder and the control box must be grounded according to electrical installation regulations. This grounding is necessary to ensure electrical safety and the proper functioning of the equipment.

Seven points to follow when installing a vibrating feeder

- Check the Unit Integrity: Ensure all components are intact before installation.

- Connection Securement: Tighten connection bolts between the trough and the exciter if installed separately.

- Balance Suspension: Adjust all four vibration isolators to achieve proper balance.

- Lateral Alignment: Confirm the trough’s lateral level to prevent material deviation.

- Maintain Clearances: Abide by the recommended longitudinal and lateral clearance distances.

- Loosen Inspection Screws: For electromagnetic vibratory feeders, release exciter housing inspection screws post-installation.

- Grounding: Follow electrical regulations for grounding both the feeder’s housing and control box.

Installation Precautions Table

| Aspect | Recommendation |

|---|---|

| Whole-Unit Installation | Install the complete unit whenever possible. |

| Suspended Installation | Balance vibration isolators and ensure lateral level alignment. |

| Clearances | Maintain recommended longitudinal and lateral clearance distances. |

| Preparing for Operation | Loosen inspection screws on electromagnetic vibratory feeders. |

| Electrical Grounding | Ground feeder housing and control box as per electrical norms. |

Requirements for the installation of vibrating feeders

- The vibrating feeder should generally be installed on the working position as a whole. If the site conditions require the tank and the exciter to be disassembled for installation, care must be taken to carefully tighten the connecting bolts between the exciter and the tank when installing the vibrator on the tank.

- For hanging installation, the four shock absorbers must be adjusted and balanced, and the horizontal level of the tank body should be checked, otherwise the material will shift to one side during the feeding process.

- Since the vibrating feeder may sway during operation, keep a certain distance between the vibrating feeder and other nearby objects to avoid collisions. The minimum vertical spacing is 50-100 mm, and the minimum horizontal spacing is 25-50 mm.

- After the installation is completed, the inspection screws on the upper and lower sides of the exciter housing must be loosened for the electric vibration feeder. Otherwise, the vibration of the electric vibration feeder will be hindered when driving.

- The casing of the electric vibration feeder and the control box shall be grounded according to the installation regulations of electrical equipment.

Conclusion

Proper installation of vibratory feeders is paramount for their efficient and safe operation. By following these guidelines, encompassing various installation aspects, from whole-unit installation to electrical grounding, industries can ensure the optimal performance and longevity of their vibratory feeders. Adherence to these practices promotes a seamless integration of this essential equipment into the industrial workflow.