Vibratory feeders play a pivotal role in material handling and processing industries, providing controlled and efficient transportation of bulk materials. This article explores the distinctions between electromagnetic and mechanical vibratory feeders, shedding light on their unique features, applications, and advantages.

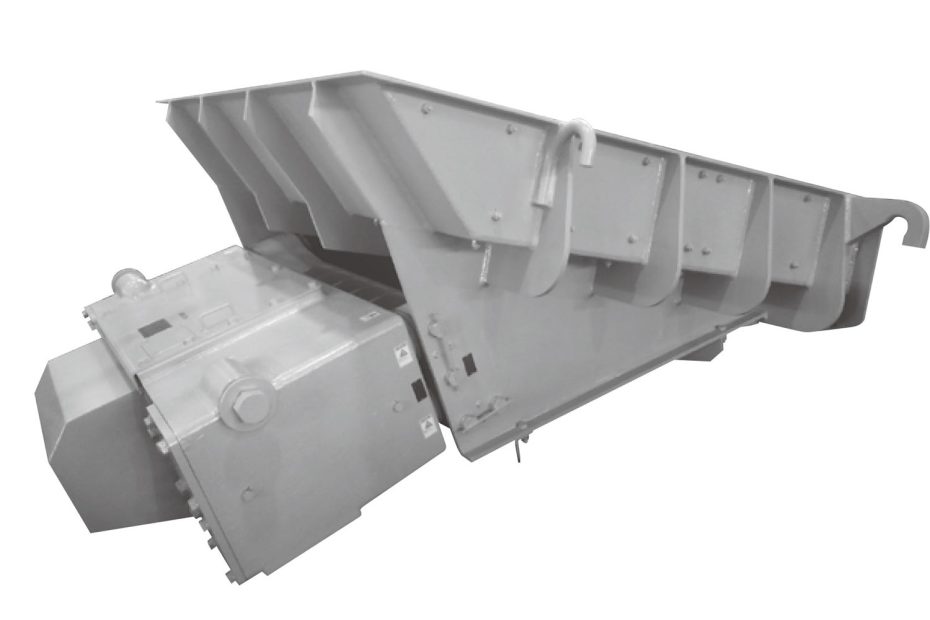

Overview Of Electromagnetic Vibratory Feeders

Working Principle

Electromagnetic vibratory feeders operate on the principle of electromagnetic vibrations. A coil is energized with a pulsating electrical current, creating a magnetic field that rapidly attracts and releases a armature, inducing vibrations. These vibrations transmit to the conveying deck, moving materials in a controlled manner.

Top 3 Advantages of Electromagnetic Vibratory Feeders

- Precise Control: Electromagnetic feeders offer fine-tuned control over vibration intensity, allowing for precise material handling.

- Instantaneous Start-Stop: The electromagnetic mechanism enables instantaneous start and stop, enhancing operational efficiency.

- Variable Feed Rates: The adjustable vibration frequency facilitates variable feed rates, accommodating diverse material requirements.

Electromagnetic Vibratory Feeders : Top 3 Applications

- Food Processing: Electromagnetic feeders excel in applications where precise ingredient dosing and gentle material handling are crucial, such as in the food industry.

- Pharmaceuticals: The ability to control vibration intensity makes electromagnetic feeders ideal for pharmaceutical processes requiring accuracy.

- Packaging: In packaging lines, these feeders contribute to controlled and consistent material flow, optimizing the packaging process.

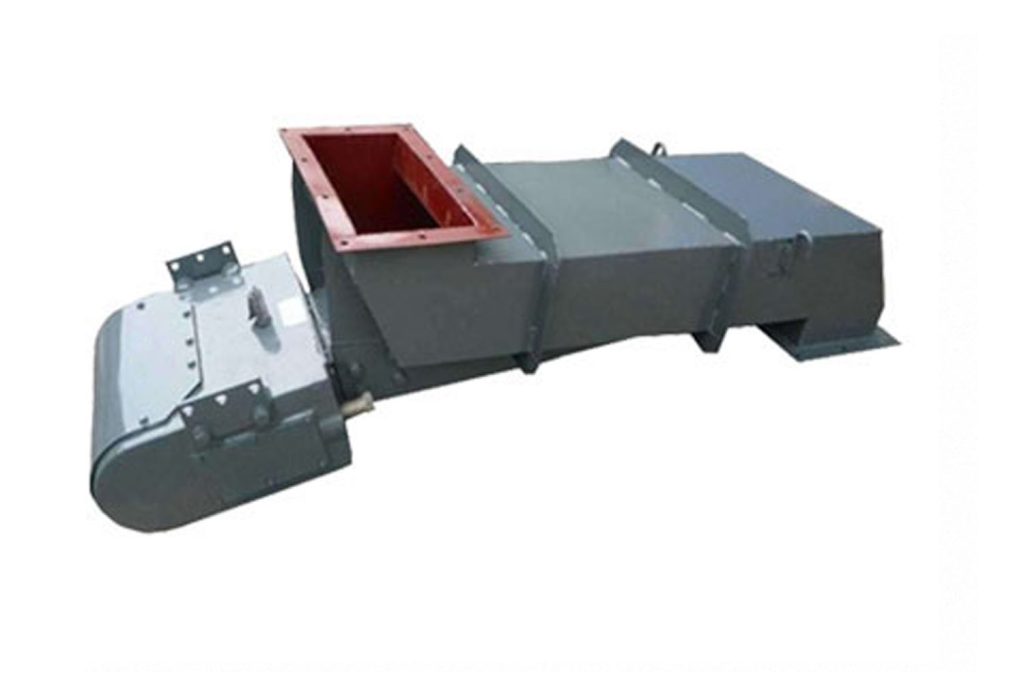

Overview Of Mechanical Vibratory Feeders

Working Principle

Mechanical vibratory feeders rely on eccentric shafts with unbalanced weights attached to generate vibrations. These vibrations transfer to the conveying deck, moving materials forward. The adjustment of the unbalanced weights regulates the amplitude of the vibrations.

Top 3 Advantages of Mechanical Vibratory Feeders

- Sturdy and Robust: Mechanical feeders are known for their robust construction, making them suitable for heavy-duty applications.

- Low Maintenance: The simplicity of the mechanical design often results in lower maintenance requirements, reducing downtime.

- High Capacity: Mechanical feeders are capable of handling larger volumes of materials, making them suitable for high-capacity operations.

Mechanical Vibratory Feeders : Top 3 Applications

- Mining: Mechanical feeders are widely used in the mining industry, handling bulk materials with high throughput requirements.

- Aggregates: In the production of aggregates, mechanical feeders contribute to the efficient transportation of materials for further processing.

- Steel Manufacturing: The robust nature of mechanical feeders suits them for the harsh environments of steel manufacturing plants.

Electromagnetic vs. Mechanical: A Comparative Table

| Criteria | Electromagnetic Vibratory Feeders | Mechanical Vibratory Feeders |

|---|---|---|

| Working Principle | Electromagnetic vibrations | Eccentric shafts with unbalanced weights |

| Control of Vibrations | Precise control | Adjustable unbalanced weights for amplitude control |

| Start-Stop Capability | Instantaneous start-stop | Gradual start-stop |

| Maintenance | Moderate | Low |

| Suitability for Heavy-Duty Operations | Limited | Excellent |

| Applications | Food, Pharmaceuticals, Packaging | Mining, Aggregates, Steel Manufacturing |

Conclusion

In conclusion, the choice between electromagnetic and mechanical vibratory feeders hinges on the specific requirements of the material handling application. Electromagnetic feeders offer precision and flexibility, making them ideal for industries demanding accurate material control. On the other hand, mechanical feeders thrive in heavy-duty environments with high-volume material handling needs. Understanding the nuances of each type empowers industries to make informed decisions, aligning their vibratory feeder choice with operational demands.