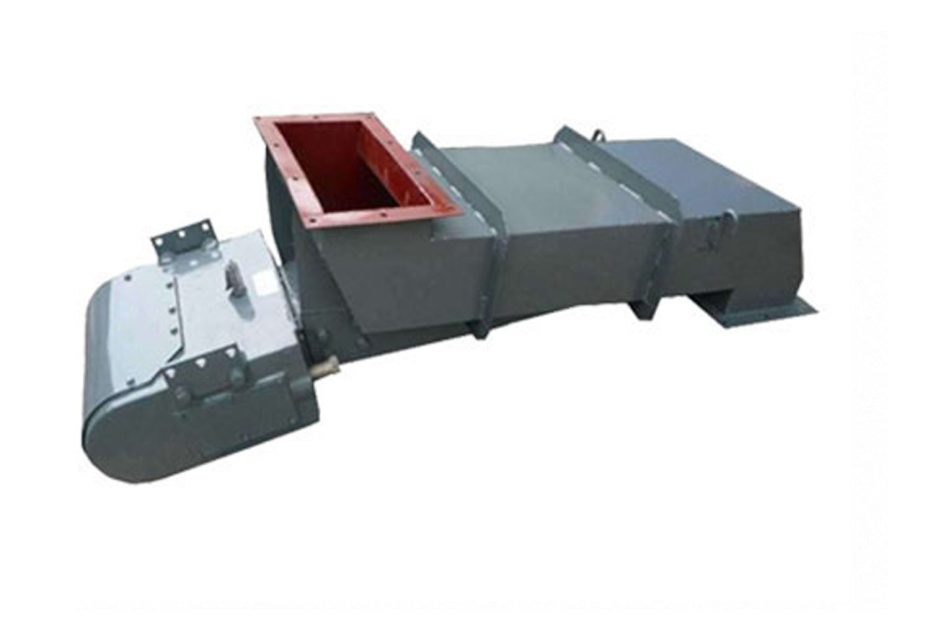

The electromagnetic vibrating feeder is used to uniformly or quantitatively supply materials from the storage bin or other storage equipment to the receiving equipment. It is an essential equipment for the automation of flow operations.

The electromagnetic vibrating feeder has a simple structure, is easy to operate, does not require lubrication, and consumes little power. The ore feeding amount can be adjusted evenly. This equipment is mainly used for quantitative or continuous supply of block, granular or powdery materials. Widely used in mining, metallurgy, coal, electric power, chemical industry, food, glass, refractory materials and other industries.

Electromagnetic vibrating feeders play a crucial role in various industries, ensuring a steady and controlled flow of materials. However, like any complex machinery, they are prone to encountering problems.

Three Common Problems And Solutions For Electromagnetic Vibrating Feeders

1. Inconsistent Material Flow

One prevalent issue users encounter is inconsistent material flow. This problem can be attributed to irregular vibrations caused by factors like uneven material distribution or improper feeder settings.

Solution: Adjusting Feeder Settings

To tackle inconsistent material flow, carefully adjust the feeder’s settings such as vibration intensity and frequency. Additionally, ensure that the material is evenly distributed across the feeder tray to promote a smoother flow.

2. Electromagnetic Interference

Electromagnetic interference can disrupt the normal functioning of vibrating feeders, leading to operational inefficiencies.

Solution: Shielding and Isolation Techniques

Implementing electromagnetic shielding around the feeder system can minimize interference. Additionally, consider isolating the feeder from other electronic equipment to reduce the impact of external electromagnetic sources.

3.Overheating Issues

Excessive heat generation in electromagnetic vibrating feeders can result from prolonged operation or inadequate cooling mechanisms.

Solution: Optimize Cooling Systems

Ensure that the feeder has adequate cooling mechanisms in place. This may involve improving ventilation or incorporating cooling fans to prevent overheating during extended usage.

The Importance of Regular Maintenance

Regular maintenance is key to preventing and addressing potential issues with electromagnetic vibrating feeders. Neglecting maintenance can lead to the exacerbation of common problems and may result in costly repairs.

| Maintenance Task | Frequency |

|---|---|

| Check for loose connections | Weekly |

| Lubricate moving parts | Monthly |

| Inspect electrical components | Quarterly |

| Clean and remove debris | Biannually |

Conclusion

Addressing common problems in the application of electromagnetic vibrating feeders involves a combination of proper initial setup, troubleshooting techniques, and consistent maintenance. By adjusting feeder settings, implementing shielding measures, optimizing cooling systems, and adhering to a regular maintenance schedule, users can ensure a smooth and efficient material feeding process.