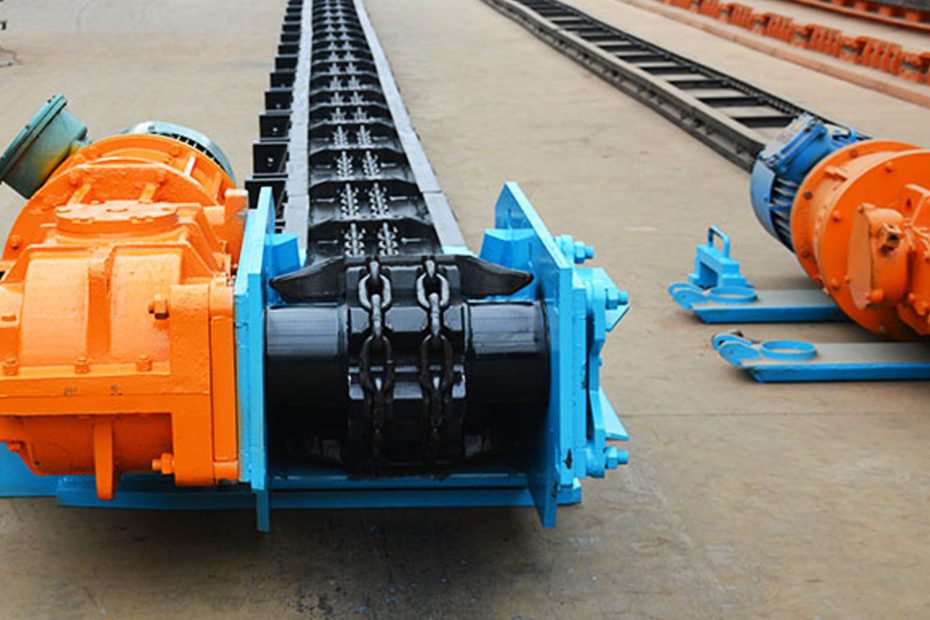

Scraper conveyor is a continuous conveying machine with flexible traction components, which can be used to convey bulk materials such as dust, small particles and small blocks in horizontal, inclined and vertical directions. It is often used in coal mines, metallurgy, building materials, chemicals, etc. Various industrial fields.

Scraper conveyor is a commonly used material conveying equipment. It uses scraper traction machinery to move materials from one place to another. It can convey materials in a sealed manner, with high work efficiency, energy saving and environmental protection.

7 key points for maintaining scraper conveyors

Regular maintenance and replacement of parts are indispensable links in the use of scraper conveyors. Maintenance and replacement of effective parts can ensure the normal operation of the transmission system, thereby avoiding accidents caused by equipment failure. The following will introduce how to maintain and replace parts correctly from the following aspects.

- Lubrication and maintenance: Fill the transmission system of the scraper conveyor with an appropriate amount of lubricating oil to reduce wear and noise of parts

- Replace the scraper: usually observe the use of the scraper, detect the wear degree of the scraper in time and replace it.

- Chain replacement: timely detect the use of the chain, and replace the severely worn chain in time.

- Cleaning: The scraper conveyor should be cleaned frequently during use to clean up the accumulated materials and dust, especially the easily polluted parts such as the scraper and sprocket of the scraper conveyor should be cleaned in time, otherwise it will affect the normal operation of the equipment .

- Reinforcement: Frequently check the fastening of important parts and reinforce loose parts in time to ensure that the equipment does not fail unexpectedly during operation.

- Detection of equipment failure: The detection and elimination of equipment failure is an important part of the maintenance of scraper conveyors. When the equipment fails, it needs to be eliminated in time, and the cause of the failure and the solution should be recorded, so as to better improve the operating efficiency of the equipment.

- Replacement of accessories: Repair and maintain the accessories of the scraper conveyor, such as drive motors, reducers, bearings, etc., and replace damaged accessories in time to ensure the normal operation of the equipment.

In Summary

During the use of the scraper conveyor, attention should be paid to the safety of the equipment, regular maintenance and replacement of parts are required to ensure the normal operation and working efficiency of the equipment.