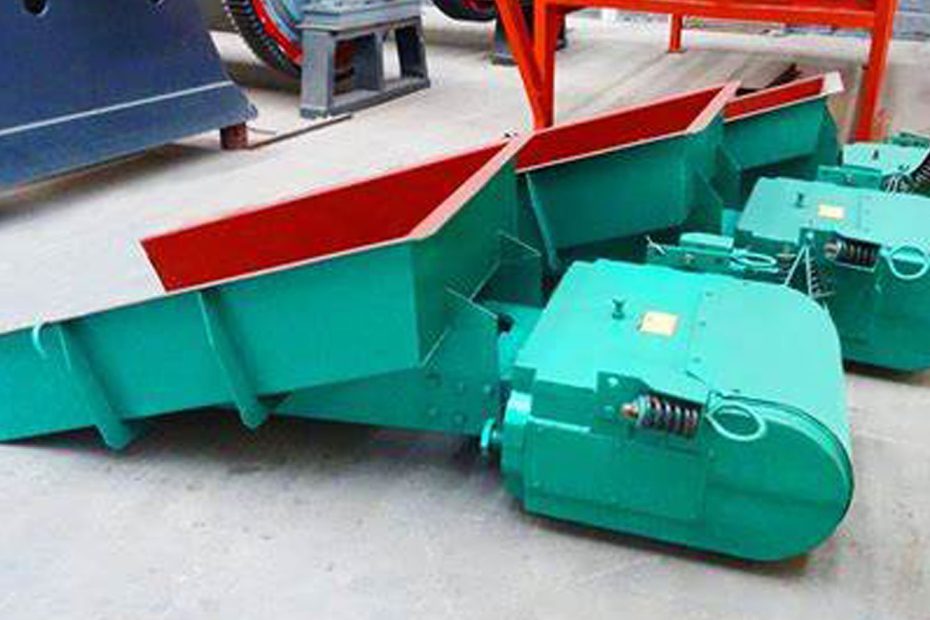

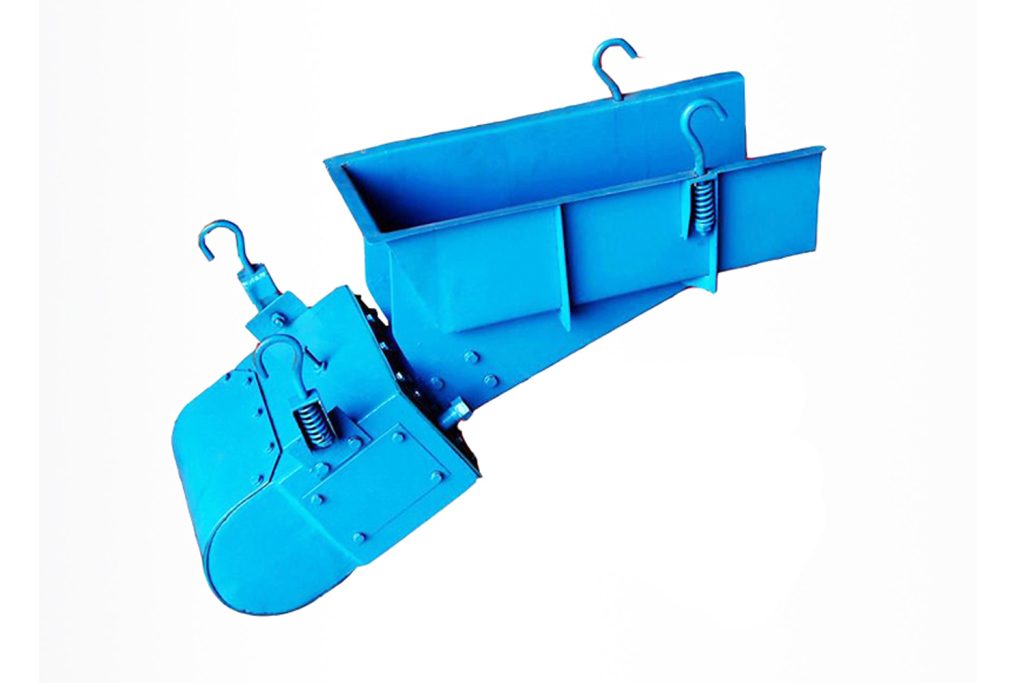

In the dynamic landscape of industrial automation, the electromagnetic vibratory feeder stands out as a vital component facilitating the seamless movement of materials.

The electromagnetic vibrating feeder is used to uniformly or quantitatively supply block, granular or powdery materials from storage silos or other storage equipment to the receiving equipment. It is an essential equipment for the automation of flow operations.

The electromagnetic vibrating feeder has a simple structure, small size, easy installation and operation, no rotating parts, no need for lubrication, easy maintenance, and low power consumption. The ore feeding amount can be adjusted evenly. This equipment is widely used in mining, metallurgy, coal, electric power, chemical industry, food, glass, refractory materials and other industries.

Operational Principles

Electromagnetic vibratory feeders operate on the principle of electromagnetic vibrations to convey materials. A coil, energized with alternating current, generates a magnetic field that interacts with an armature attached to the feeder’s tray. This interaction produces linear vibrations, propelling the material forward. The amplitude and frequency of these vibrations can be precisely controlled, allowing for tailored feeding in various industrial settings.

Advantages of Electromagnetic Vibratory Feeders

1. Precise Material Handling :The precision achieved with electromagnetic vibratory feeders is unparalleled. By controlling the intensity and frequency of vibrations, these feeders can handle a wide range of materials, from fine powders to larger particles, with exceptional accuracy. This level of precision is particularly crucial in industries like pharmaceuticals and electronics, where precise material placement is paramount.

2. Low Maintenance Requirements:Electromagnetic vibratory feeders boast a simple design with fewer mechanical components, translating to lower maintenance requirements. The absence of belts, pulleys, and other traditional wear-prone parts reduces the likelihood of breakdowns, ensuring consistent operation over extended periods. This feature makes them a cost-effective choice for industries with high-volume material handling needs.

Industrial Applications of Electromagnetic Vibratory Feeders

1. Food Processing Industry :

In the food processing industry, where hygiene and precision are paramount, electromagnetic vibratory feeders find extensive use. These feeders facilitate the controlled and sanitary movement of ingredients, ensuring accurate dosing in processes such as mixing, packaging, and filling. The versatility of these feeders allows them to handle a wide range of food products, from granules to powders.

Key Features Benefiting the Food Processing Industry

- Hygienic Design: Easy-to-clean surfaces and stainless-steel construction ensure compliance with food safety standards.

- Accurate Dosing: Precise control over vibrations enables accurate dosing of ingredients, reducing waste and ensuring product consistency.

Comparison of Vibratory Feeder Types

| Feeder Type | Operational Principle | Advantages | Industrial Applications |

|---|---|---|---|

| Electromagnetic Vibratory | Electromagnetic vibrations | Precise material handling, low maintenance | Food processing, Pharmaceuticals |

| Mechanical Vibratory | Mechanical vibrations through eccentric drives | Robust design, suitable for heavy-duty applications | Mining, Construction, Recycling |

| Vibrating Grizzly | Vibrations produced by eccentric weights | Efficient screening, handling large volumes | Mining, Aggregate processing, Construction |

2. Pharmaceutical Industry

In pharmaceutical manufacturing, where stringent regulations govern every aspect of production, electromagnetic vibratory feeders shine. Their ability to handle powders and granules with precision makes them ideal for processes like tablet pressing and capsule filling. The hygienic design ensures compliance with industry standards, contributing to the overall quality of pharmaceutical products.

Conclusion

In conclusion, the electromagnetic vibratory feeder stands as a beacon of efficiency in industrial material handling. Its precise operational principles, coupled with low maintenance requirements, make it a preferred choice in various industries. The inclusion of a list highlighting key features beneficial to the food processing industry, a comparative table detailing different vibratory feeder types, and a case study in automotive manufacturing adds depth to the exploration of these feeders. As technology continues to evolve, electromagnetic vibratory feeders are poised to play an even more significant role in shaping the future of industrial automation, providing efficient solutions for material handling challenges across diverse sectors.